Aluminum-containing negative electrode material, negative electrode plate and lithium ion secondary battery

A technology of negative electrode material and negative electrode sheet, which is applied in the direction of secondary battery, secondary battery repair/maintenance, battery electrode, etc., can solve the problems of poor battery cycle performance and low battery energy density, and achieve high energy density and good cycle The effect of stability and high security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033]The preparation method of the secondary battery can employ various methods well known to those skilled in the art, for example, may include the following steps:

[0034] (1) Preparation of a positive electrode: Positive pole slurry is applied to the preparation of a positive electrode sheet in the positive electrode current collector of the aluminum foil;

[0035] (2) Preparation of negative electrode sheet: It is called the amount of different components, first of all, the binder PVDF and / or NMP is first formed into colloquilis (such as using PVDF and NMP, the proportion of the two can be used by the art. The person is set), then the modifier is mixed, then the aluminum powder is stirred and dispersed to obtain a modified aluminum powder, and then the conductive agent is added to stir dispersion, so that the aluminum powder is uniformly dispersed in the conductive agent, and finally add graphite negative electrode active materials. The stirring dispersion forms a uniform ...

Embodiment 1

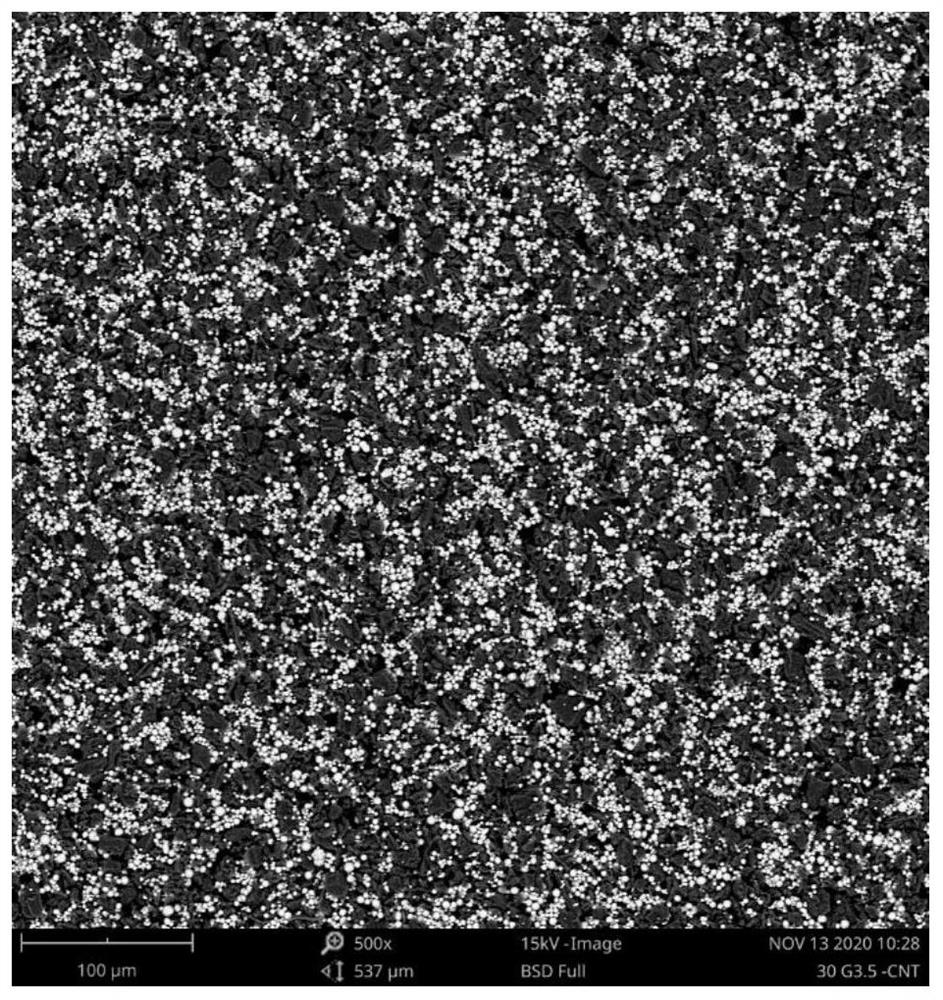

[0039] Example 1: Lithium ion secondary battery of an aluminum-containing negative electrode sheet obtained by an aluminum-containing negative electrode material of the present invention

[0040] The positive electrode material uses lithium nickel-watery (NCM), and the negative electrode uses a new type of negative electrode material, wherein the aluminum powder in the novel negative electrode material is D50 6.0 um, the graphite is a human graphite of D50 15 um, and the current collector is an 8 um copper foil. Lithium nickel-channlate (NCM) positive electrode material with a capacity of 160 mAh / g, a PVDF, conductive carbon black, is applied to the double-sided aluminum foil as a positive electrode sheet; 340 mAh is 340 mAh G's artificial graphite negative electrode material and a total battery design of 750 mAh / g of aluminum powder, modifier polyacrylonitrile (PAN), conductive carbon black SP, binder PVDF Press 64: 30: 1: 2: 3 ratio And then the binder PVDF is first formed i...

Embodiment 2-6

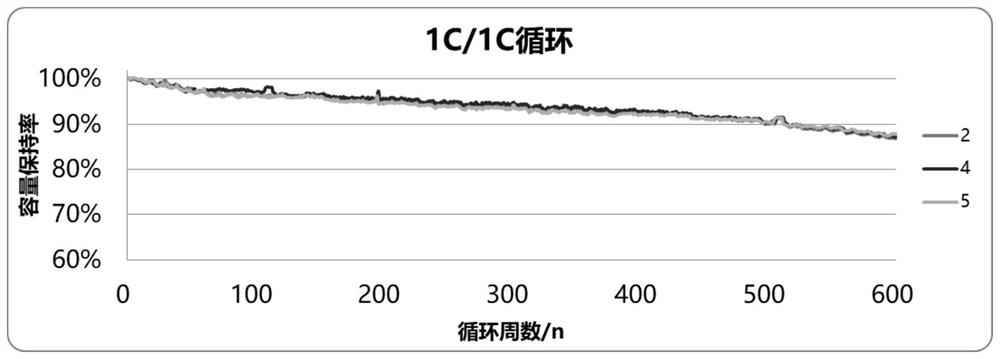

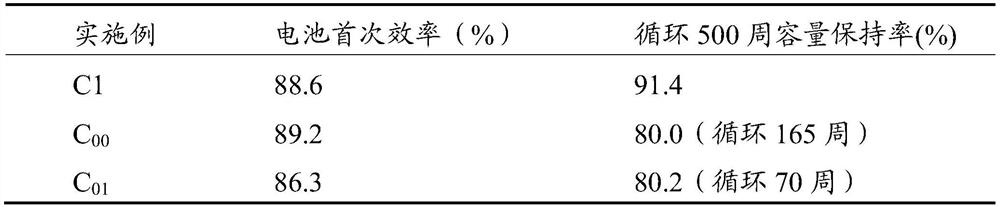

[0050] Example 2-6: Effect of different content ratios of modifier polyclinne (PAN) on battery performance

[0051] Example 2-6 Different in the first embodiment, the proportion of modified polyacrylonitrile (PAN) content in the negative electrode sheet, and the positive electrode, the negative electrode sheet, the electrolyte and the battery preparation step are the same, and polypropylene in the negative electrode plate The content ratio of nitrile (PAN) is 0.5% to 3%. The charging and discharge rate of the battery of Example 2-10 at 0.5 C is performed under the voltage range of 2.5 to 4.2 V, and the charge and discharge test is performed, and the test results are as follows: Table 2 below.

[0052] Table 2. Example 1-6 Battery Test Data

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com