Preparation method of lithium battery positive electrode material having high specific discharge capacity

A positive electrode material and lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low lithium ion diffusion coefficient and electronic conductivity, unsatisfactory material rate performance, and low initial charge and discharge efficiency. Achieve the effects of good high temperature and high current cycle characteristics, excellent rate cycle performance, and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

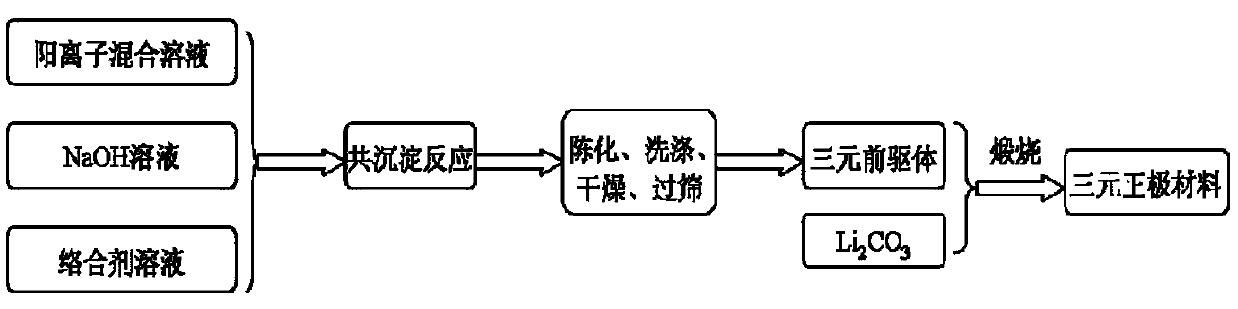

[0044] The present invention also provides a method for preparing the above-mentioned positive electrode material, comprising the following steps:

[0045] 1) Weigh the nickel source compound, cobalt source compound, and manganese source compound according to the stoichiometric ratio, and dissolve them in deionized water to prepare a cation mixed solution with a concentration of 2mol / L;

[0046] 2) According to the complexing agent and the cation concentration ratio in step 1) of 0.1-1.2:1, weigh the lactic acid complexing agent C 3 h 6 o 3 prepared as a solution;

[0047] 3) Weigh NaOH solution with a concentration of 2mol / L as a precipitant;

[0048] 4) Add the above three solutions into the reaction kettle at the same time through the peristaltic pump, adjust the feeding speed of the peristaltic pump to change the concentration ratio of the complexing agent and the cationic solution, and control the pH value of the mixed solution in the reaction kettle to always be kept ...

Embodiment 1

[0066] A preparation method of lithium battery cathode material with high discharge specific capacity is realized according to the following steps:

[0067] 1) Weigh a certain amount of nickel sulfate (NiSO 4 ·7H 2 O), cobalt sulfate (CoSO 4 ·6H 2 O) and manganese sulfate (MnSO 4 ·H 2 O), dissolved in deionized water to prepare a concentration of cation mixed solution of 2mol / L;

[0068] 2) Take a certain amount of lactic acid complexing agent C according to the ratio of complexing agent and cation concentration in step 1) of 1:1 3 h 6 o 3 prepared as a solution;

[0069] 3) Weigh a certain amount of NaOH solution with a concentration of 2mol / L as a precipitant;

[0070] 4) Add the above three solutions into the reaction kettle at the same time through the peristaltic pump, adjust the feeding speed of the peristaltic pump to change the concentration ratio of the complexing agent and the cationic solution, and control the pH of the mixed solution in the reaction kettle...

Embodiment 2

[0077] A preparation method of lithium battery cathode material with high discharge specific capacity is realized according to the following steps:

[0078] 1) Weigh a certain amount of nickel sulfate (NiSO 4 ·7H 2 O), cobalt sulfate (CoSO 4 ·6H 2 O) and manganese sulfate (MnSO 4 ·H 2 O), dissolved in deionized water to prepare a concentration of cation mixed solution of 2mol / L;

[0079] 2) Take a certain amount of lactic acid complexing agent C according to the ratio of complexing agent and cation concentration in step 1) of 1:1 3 h 6 o 3 prepared as a solution;

[0080] 3) Weigh a certain amount of NaOH solution with a concentration of 2mol / L as a precipitant;

[0081] 4) Add the above three solutions into the reaction kettle at the same time through the peristaltic pump, adjust the feeding speed of the peristaltic pump to change the concentration ratio of the complexing agent and the cationic solution, and control the pH of the mixed solution in the reaction kettle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com