Preparation method of antibacterial stainless steel tableware

An antibacterial stainless steel and stainless steel technology, applied in the direction of manufacturing tools, heat treatment equipment, furnace types, etc., can solve the problems that the surface coating wear or fall off can not be effectively solved, the waste of antibacterial stainless steel, increase the processing flow, etc., to achieve good antibacterial effect, High metallurgical bonding strength and strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

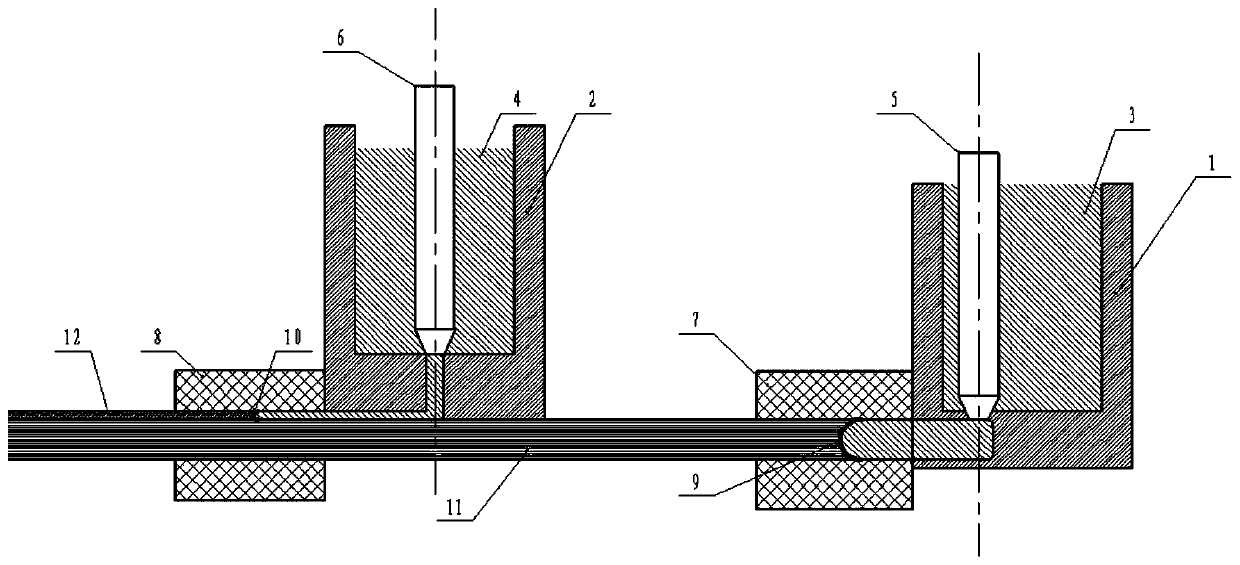

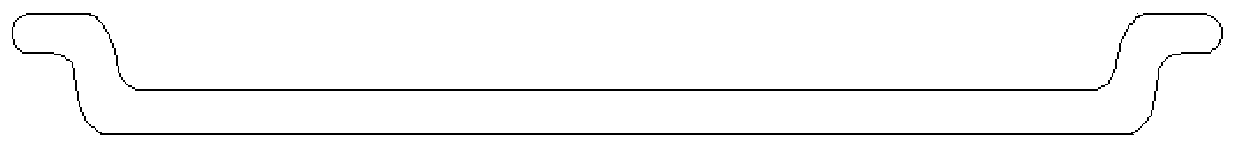

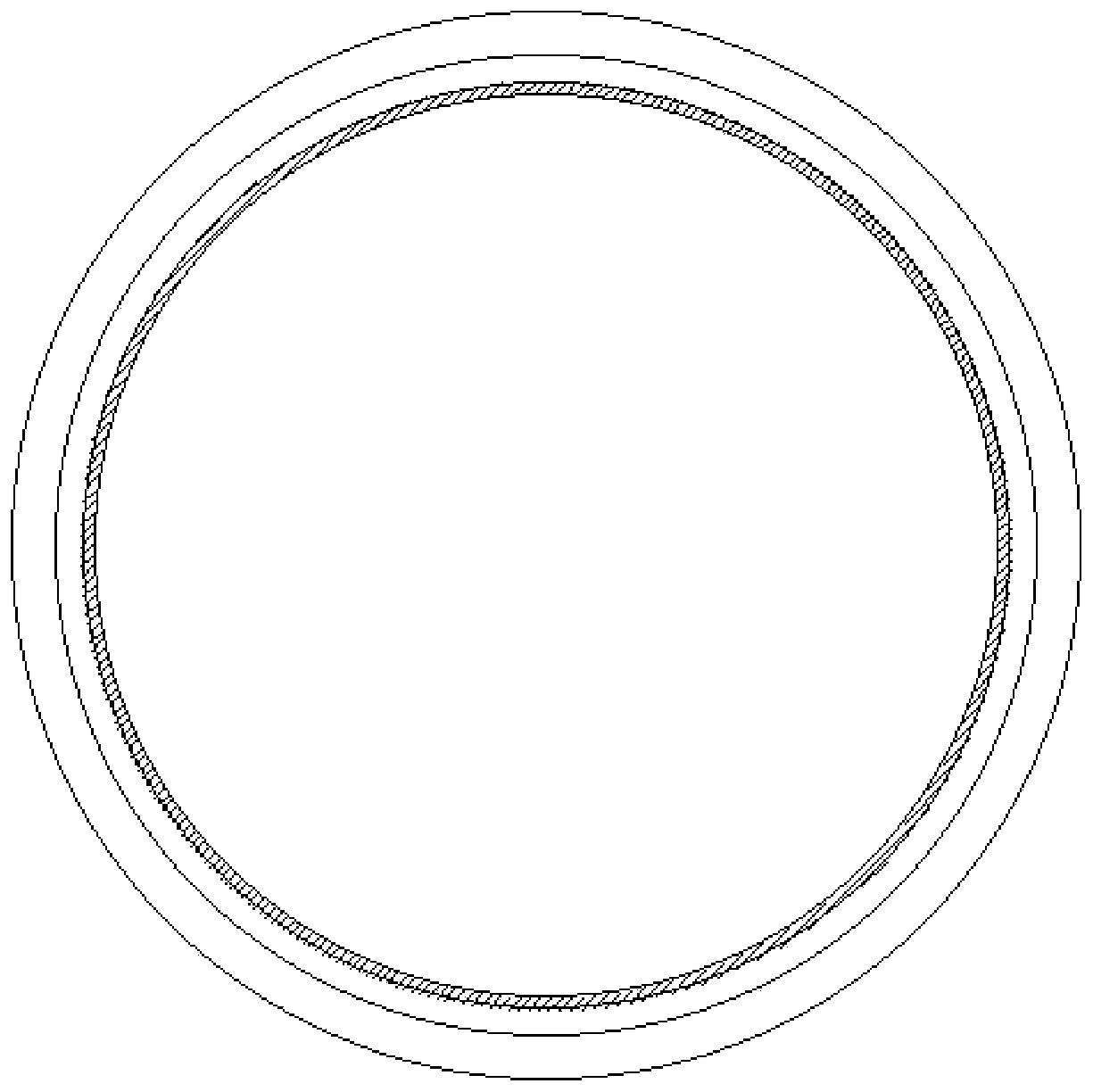

[0034] The following will clearly and completely describe the technical solutions in the embodiments of the present application with reference to the accompanying drawings in the embodiments of the present application. Obviously, the described embodiments are only for illustration, and are not intended to limit the present application.

[0035] The whole process of the preparation method of an antibacterial stainless steel tableware disclosed by the present invention is schematically described below.

[0036] (1) Structure and component design

[0037] The antibacterial stainless steel material for tableware provided by the present invention basically consists of a double-layer structure of steel forming a base and steel forming a surface antibacterial layer. Since the surface antibacterial layer is located on the surface of the substrate in the processed tableware products, the substrate is generally not in direct contact with food during use, so the strength performance and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com