A kind of preparation technology of environment-friendly high-transparency hot-melt composite film

A preparation process and composite film technology, which is applied to synthetic resin layered products, devices for coating liquid on the surface, coatings, etc., can solve the problems of limited application range, poor transparency of hot-melt composite films, and transparency cannot be changed. , to improve mechanical properties, prevent volatilization loss, and improve anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

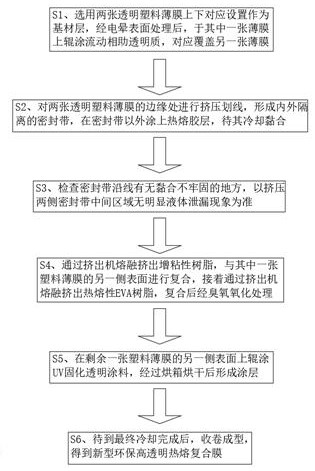

[0049] see figure 1 , a preparation process of an environmentally friendly high-transparency hot-melt composite film, comprising the following steps:

[0050] S1. Select two transparent plastic films and set them up and down correspondingly as the substrate layer. After corona surface treatment, roll-coat flow-assisted transparent substance on one of the films, and cover the other film correspondingly;

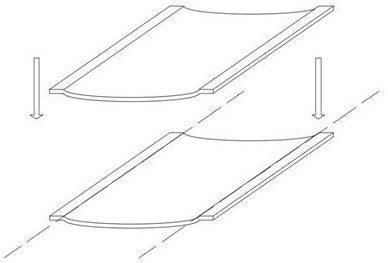

[0051] S2. Squeeze and mark the edges of the two transparent plastic films to form an internally and externally isolated sealing tape, coat the outside of the sealing tape with a hot-melt adhesive layer, and wait for it to cool and bond;

[0052] S3. Check whether there is any weak adhesion along the sealing belt, and the middle area of the sealing belt on both sides of the extrusion shall be subject to no obvious liquid leakage;

[0053] S4. Melt and extrude the tackifying resin through the extruder, compound it with the other side surface of one of the plastic films, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com