Collagen hydrophobic modifier, preparation method thereof and method for modifying collagen

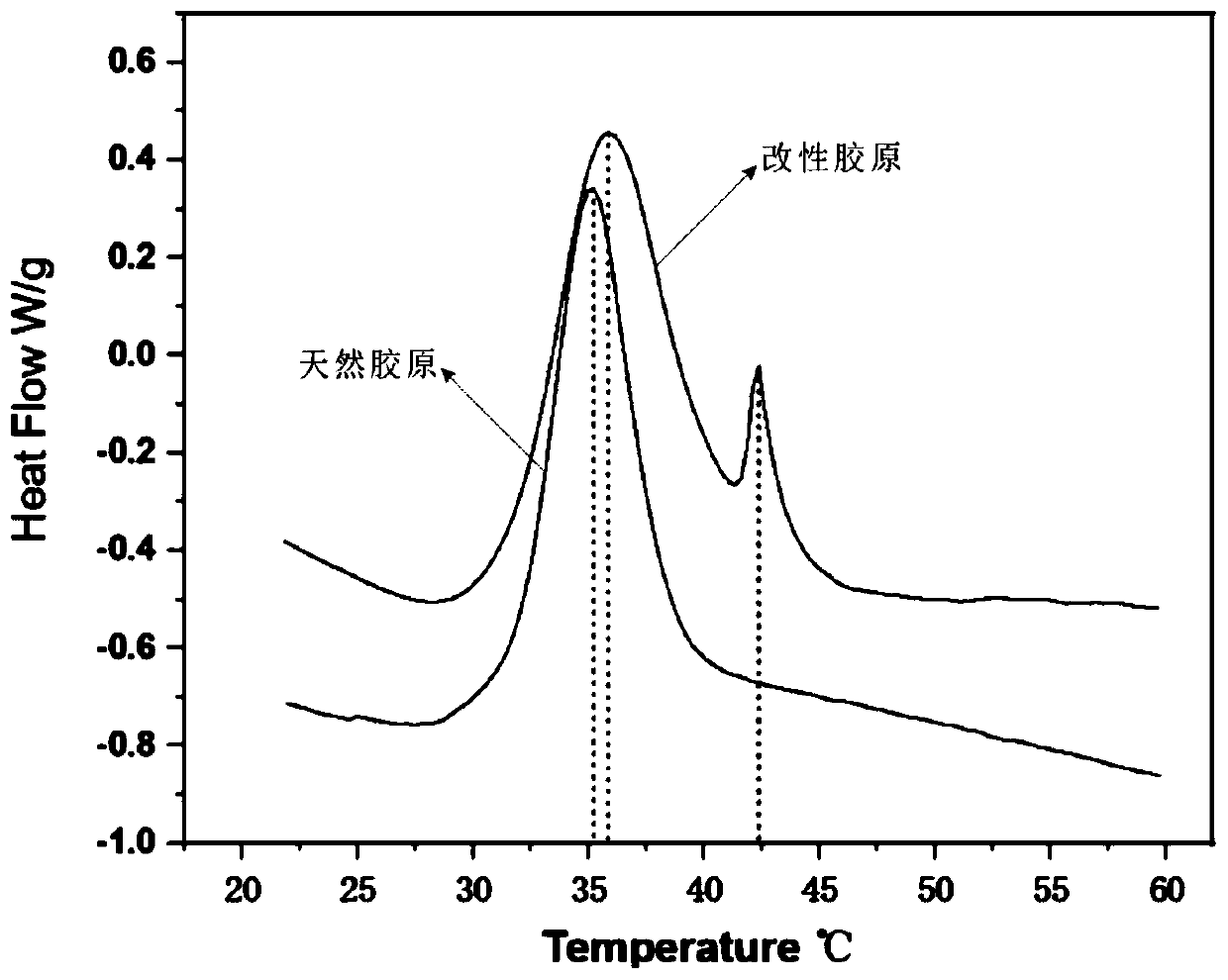

A hydrophobic modifier and collagen technology, applied in textiles and papermaking, single-component protein rayon, fiber chemical characteristics, etc., can solve the problems of easy introduction of toxicity by organic solvents, low modification efficiency, and difficulty in control, and achieve improvement Structural stability and electrostatic spinnability, improving hydrophobicity, and reducing denaturation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

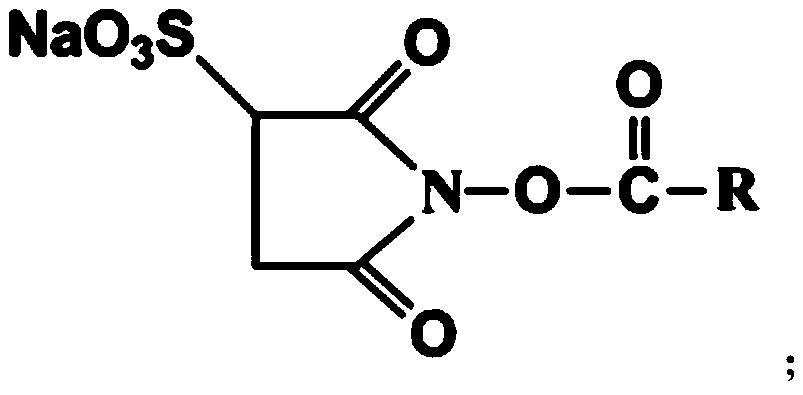

[0034] A preparation method of collagen hydrophobic modifier, comprising the following steps:

[0035] Dissolve 0.1 part of lauric acid in 1 part of dimethylformamide (DMF) and place in a 100 mL round bottom flask. Afterwards, weigh 0.5 part of thio-NHS and 0.5 part of dicyclohexylcarbodiimide, add them in sequence to the DMF solution of lauric acid, keep stirring under closed conditions, and react at room temperature for 2 hours. After the reaction was over, the insoluble matter was removed by filtration and the filtrate was collected. Add 0.5 parts of ethyl acetate, let it stand for 48 hours, precipitate out, filter the filter cake, dry in air, and obtain lauric acid-thio NHS ester.

[0036] A method for modifying collagen, comprising the steps of:

[0037] Weigh 10 parts of fish skin collagen and dissolve in 5 parts of 0.1 mol / L acetic acid solution. After the collagen is completely dissolved, add 0.5 mol / L NaOH solution to adjust the pH to 9-10. Add 0.01 part of lauric ...

Embodiment 2

[0039] A preparation method of collagen hydrophobic modifier, comprising the following steps:

[0040] 10 parts of octanoic acid was dissolved in 20 parts of dimethylformamide (DMF) and placed in a 100 mL round bottom flask. Afterwards, 20 parts of thio-NHS and 30 parts of dicyclohexylcarbodiimide were weighed, added sequentially to the DMF solution of octanoic acid, stirred under airtight conditions, and reacted at room temperature for 2 hours. After the reaction was over, the insoluble matter was removed by filtration and the filtrate was collected. Add 50 parts of ethyl acetate, let it stand for 2 hours, precipitate out, collect the filter cake by filtration, and dry in air to obtain octanoic acid-thio NHS ester.

[0041] A method for modifying collagen, comprising the steps of:

[0042] Weigh 150 parts of porcine cartilage collagen and dissolve in 50 parts of 0.1 mol / L acetic acid solution. After the collagen is completely dissolved, add 5 mol / L NaOH solution to adjust t...

Embodiment 3

[0044] A preparation method of collagen hydrophobic modifier, comprising the following steps:

[0045] 5 parts of palmitic acid were dissolved in 10 parts of dimethylformamide (DMF) and placed in a 100 mL round bottom flask. Afterwards, weigh 10 parts of thio-NHS and 15 parts of dicyclohexylcarbodiimide, add them in order to the DMF solution of palmitic acid, keep stirring under closed conditions, and react at room temperature for 13 hours. After the reaction was over, the insoluble matter was removed by filtration and the filtrate was collected. Add 25 parts of ethyl acetate, let it stand for 24 hours, precipitate out, collect the filter cake by filtration, and dry in air to obtain palmitic acid-thio NHS ester.

[0046] A method for modifying collagen, comprising the steps of:

[0047]Weigh 80 parts of cowhide collagen and dissolve in 25 parts of 0.1 mol / L acetic acid solution. After the collagen is completely dissolved, add 3 mol / L NaOH solution to adjust the pH to 9-10. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com