Chitosan with high deacetylation degree and high molecular weight and preparation method thereof

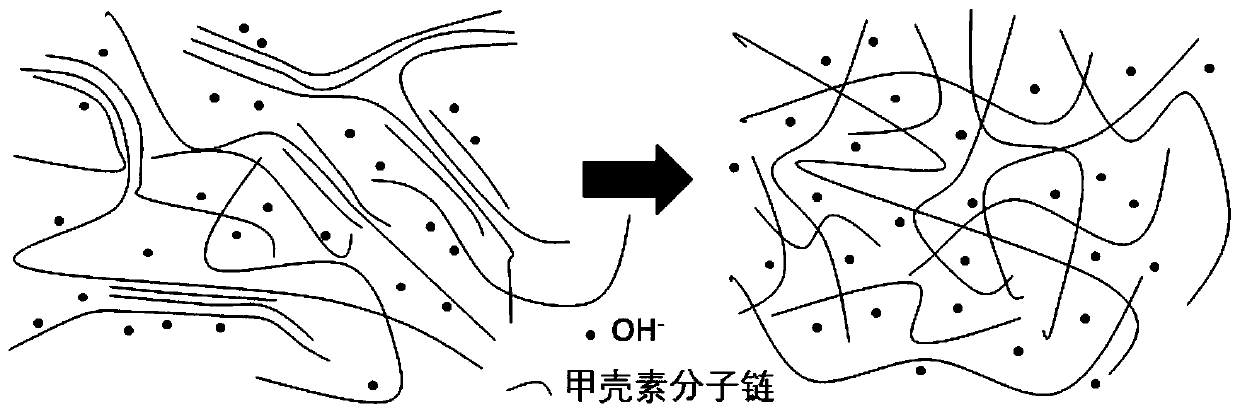

A technology with high degree of deacetylation and high molecular weight, which is applied in the field of chitosan with high degree of deacetylation and high molecular weight and its preparation, can solve the problems of cumbersome operation, high alkali concentration and reaction temperature, and low molecular weight of chitosan. Achieve the effect of increasing deacetylation concentration, mild reaction conditions and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of chitosan with high degree of deacetylation and high molecular weight, the steps are as follows:

[0032] (1) After adding chitin powder into a KOH solution with a KOH content of 18wt% to obtain a dispersion, freeze it at -30°C for 6.5 hours, filter out the undissolved part to obtain a chitin-strong alkali solution, in which the chitin The average particle size of the plain powder is 80 meshes, the degree of deacetylation is 15%, the degree of crystallinity is 45%, and the content of chitin powder in the dispersion is 4wt%;

[0033] (2) Under the condition that the temperature is 0°C, add KOH solution to the chitin-strong alkali solution, so that the KOH content in the chitin-strong alkali solution is increased to 41wt%;

[0034] (3) Carry out deacetylation reaction under the condition of 100 ℃ in temperature, make the chitosan of high degree of deacetylation and high molecular weight, wherein deacetylation reaction is carried out in microwave rea...

Embodiment 2

[0045] A preparation method of chitosan with high degree of deacetylation and high molecular weight, the steps are as follows:

[0046] (1) After adding chitin powder into a KOH solution with a KOH content of 15wt% to obtain a dispersion, freeze it at -33°C for 8 hours, filter out the undissolved part to obtain a chitin-strong alkali solution, in which chitin The average particle size of the powder is 60 mesh, the degree of deacetylation is 5%, the degree of crystallinity is 50%, and the content of chitin powder in the dispersion is 3wt%;

[0047] (2) under the condition that the temperature is 5°C, add KOH solution to the chitin-strong alkali solution, so that the KOH content in the chitin-strong alkali solution is increased to 35wt%;

[0048] (3) Carry out deacetylation reaction under the condition of 70 ℃ in temperature, make the chitosan of high degree of deacetylation and high molecular weight, wherein deacetylation reaction is carried out in microwave reactor, microwave ...

Embodiment 3

[0051] A preparation method of chitosan with high degree of deacetylation and high molecular weight, the steps are as follows:

[0052] (1) After adding chitin powder into a KOH solution with a KOH content of 22wt% to obtain a dispersion, freeze it at -34°C for 7 hours, and centrifuge the undissolved part to obtain a chitin-strong alkali solution, in which chitin The average particle size of the powder is 50 meshes, the degree of deacetylation is 10%, the degree of crystallinity is 45%, and the content of chitin powder in the dispersion is 6wt%;

[0053] (2) under the condition that the temperature is 10°C, add KOH solution to the chitin-strong alkali solution, so that the KOH content in the chitin-strong alkali solution is increased to 45wt%;

[0054] (3) Carry out deacetylation reaction under the condition of 90 ℃ in temperature, make the chitosan of high degree of deacetylation and high molecular weight, wherein deacetylation reaction is carried out in microwave reactor, mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of deacetylation | aaaaa | aaaaa |

| degree of deacetylation | aaaaa | aaaaa |

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com