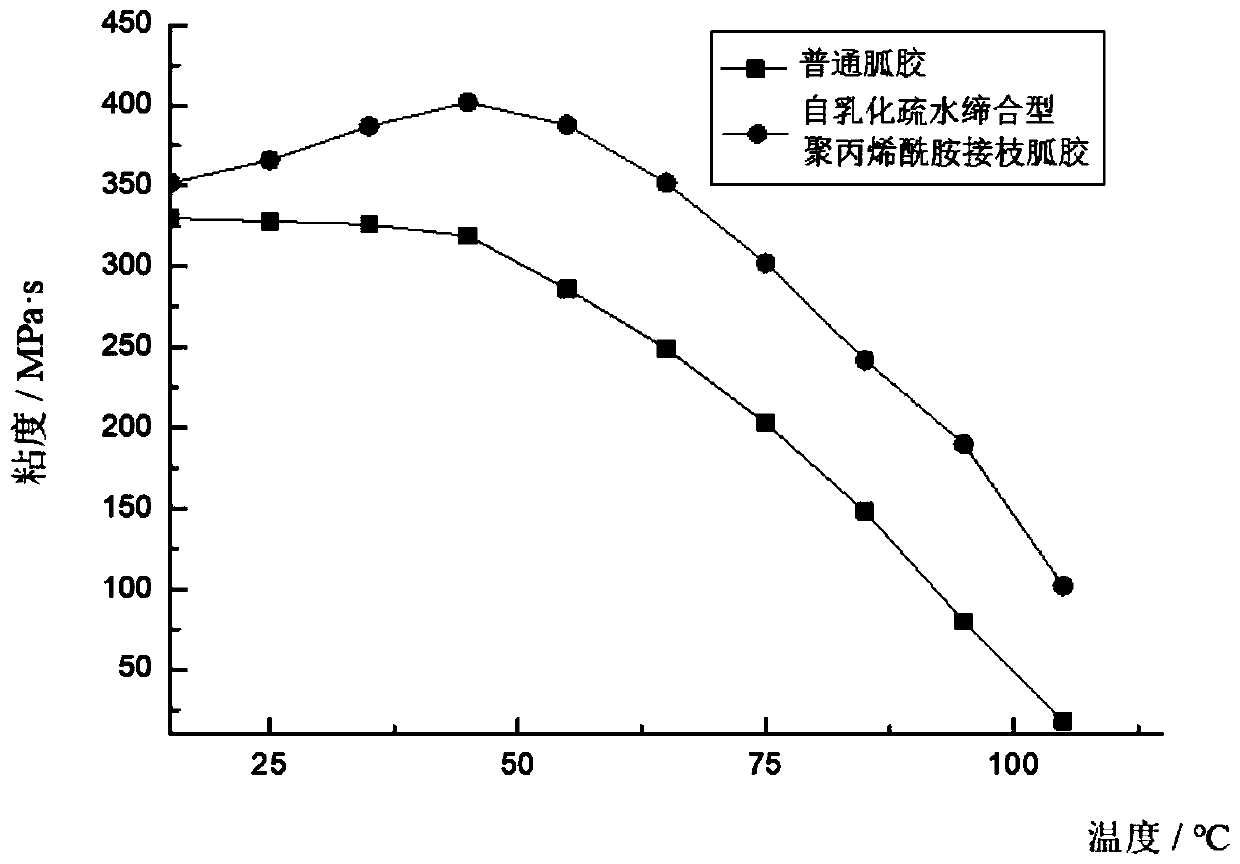

Self-emulsifying hydrophobic association type polyacrylamide grafted guanidine gum, preparation method thereof and application thereof in oil field

A technology of polyacrylamide and hydrophobic association, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve problems such as poor mineralization resistance, poor temperature resistance of guar gum, and large residue content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

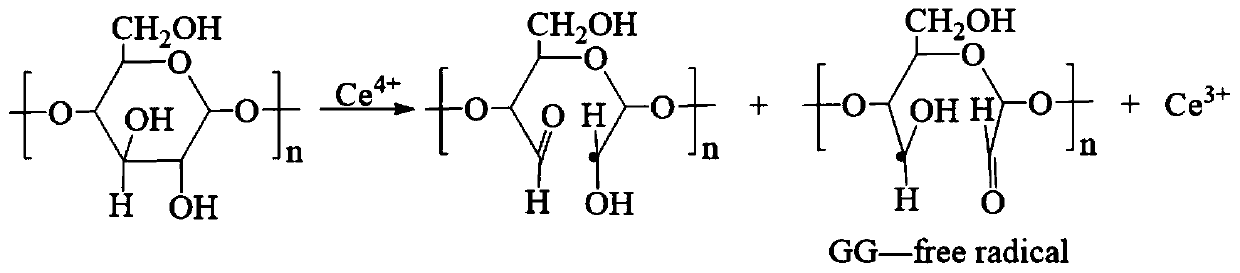

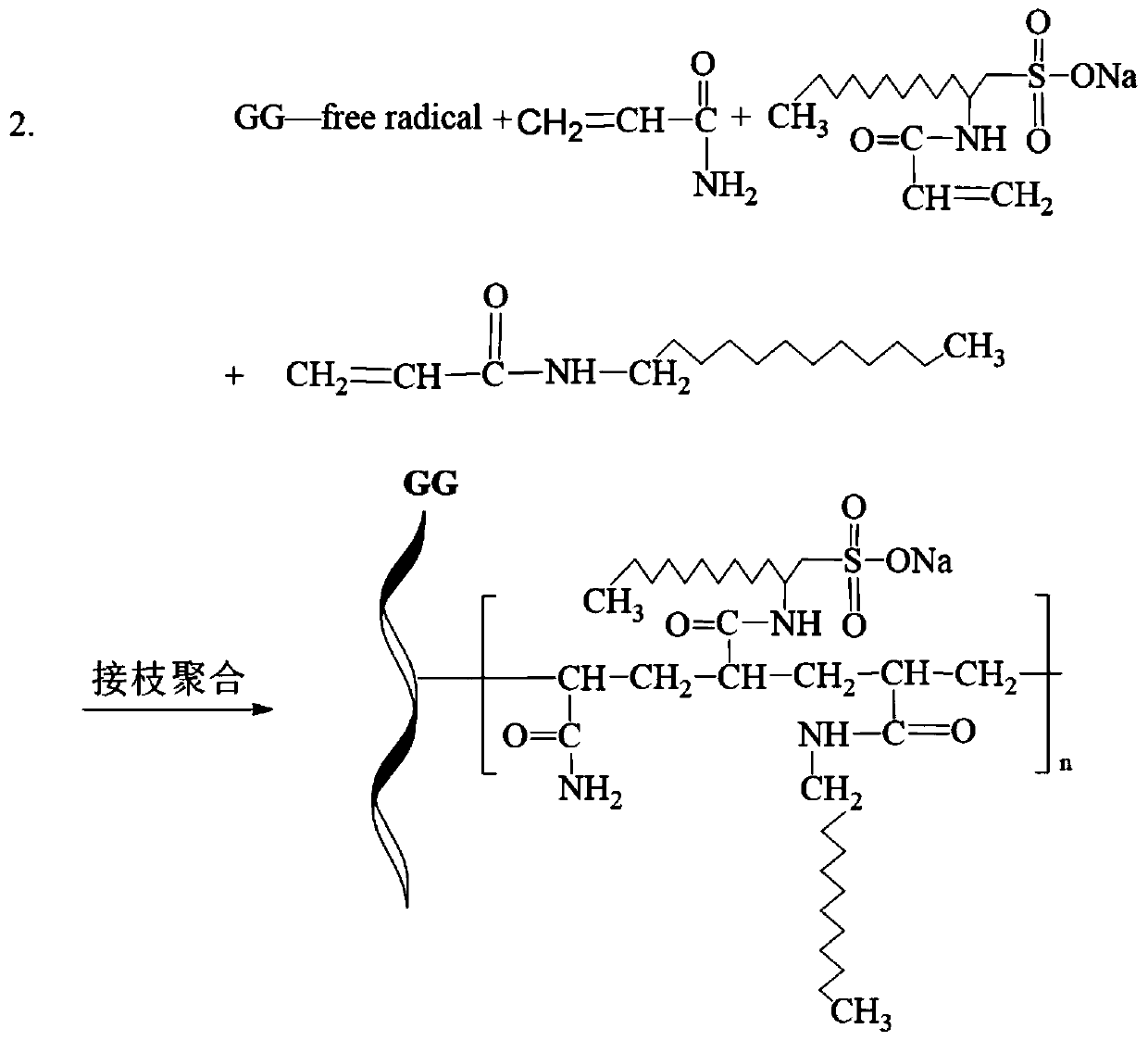

[0037] Concrete preparation process realizes by following reaction:

[0038]

[0039] Concrete, a kind of preparation method and application of self-emulsifying hydrophobic association type polyacrylamide grafted guar gum of the present invention comprise the following steps:

[0040] 1) Take 100g of paraffin and add it to a 250mL beaker, then add 10g of Span 80 (Span-80) / polyoxyethylene octylphenol ether-10 (OP-10) compound emulsifier and 3.3g of cetyl alcohol , heated and stirred to completely dissolve cetyl alcohol to obtain an oil phase. Slowly add 50-100 g of guar gum (GG) aqueous solution with a mass fraction of 2.5% into the oil phase under stirring state, and continue to stir for a period of time to obtain a reverse emulsion of guar gum.

[0041] 2) Transfer the inverse emulsion to a 250mL three-neck flask, place it in a water bath, turn it on and stir it, blow in nitrogen for 20 minutes, weigh and add 0.2-0.6g of acrylamide solution (AM), 0.2-0.6g of 2-acrylamide ...

Embodiment 1

[0049] Weigh 100g of paraffin and add it to a 250mL beaker, then add 10g of Span 80 (Span-80) / polyoxyethylene octylphenol ether-10 (OP-10) composite emulsifier and 3.3g of cetyl alcohol, and heat and stirring, so that the cetyl alcohol is completely dissolved to obtain an oil phase. Under the state of stirring, 50 g of guar gum aqueous solution with a mass fraction of 2.5% was slowly added into the oil phase, and continued to stir for a period of time to prepare the inverse emulsion of guar gum. Move the inverse emulsion to a 250mL three-necked flask, place it in a water bath, turn it on and stir, and blow nitrogen gas for 20 minutes, then weigh 0.2g of acrylamide solution, 0.3g of 2-acrylamido sodium dodecanesulfonate solution and 0.3g of N- The n-dodecylacrylamide solution was added into the three-necked flask, and the nitrogen gas was continued for 20 minutes. Add 0.02 g of the prepared initiators, stir under the condition of nitrogen gas flow, stop the nitrogen gas flow a...

Embodiment 2

[0051] Weigh 100g of paraffin and add it to a 250mL beaker, then add 10g of Span 80 (Span-80) / polyoxyethylene octylphenol ether-10 (OP-10) composite emulsifier and 3.3g of cetyl alcohol, and heat and stirring, so that the cetyl alcohol is completely dissolved to obtain an oil phase. Under the state of stirring, 50 g of guar gum aqueous solution with a mass fraction of 2.5% was slowly added into the oil phase, and continued to stir for a period of time to prepare the inverse emulsion of guar gum. Move the inverse emulsion to a 250mL three-necked flask, place it in a water bath, turn it on and stir, and blow nitrogen for 20min, then weigh 0.25g of acrylamide solution, 0.27g of 2-acrylamido sodium dodecanesulfonate solution and 0.28g of N - Add the n-dodecylacrylamide solution into the three-necked flask, and continue to pass nitrogen gas for 20 minutes. Add 0.02 g of the configured initiators, stir under the condition of nitrogen gas flow, stop the nitrogen gas flow after 30 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com