A quenched and tempered high-quality coiled tube and its manufacturing method

A manufacturing method and technology for coiled tubing, applied in manufacturing tools, furnace types, furnaces, etc., can solve the problems affecting the bending fatigue life of coiled tubing products of the whole coil, and the difference in weld structure, etc., to increase the service life and work safety. , Reduce the center segregation, improve the bending fatigue performance and the effect of stress corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

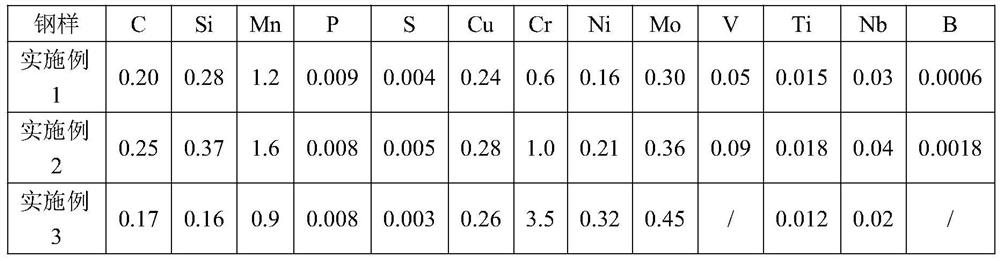

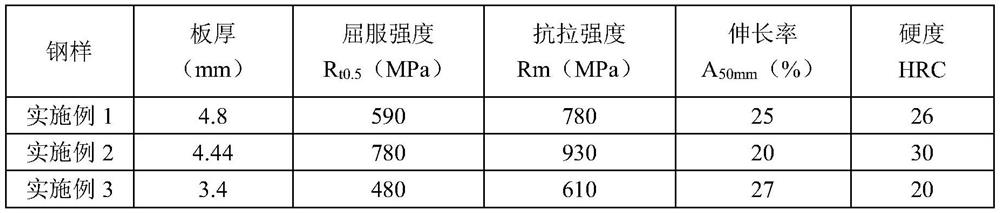

Examples

Embodiment 1

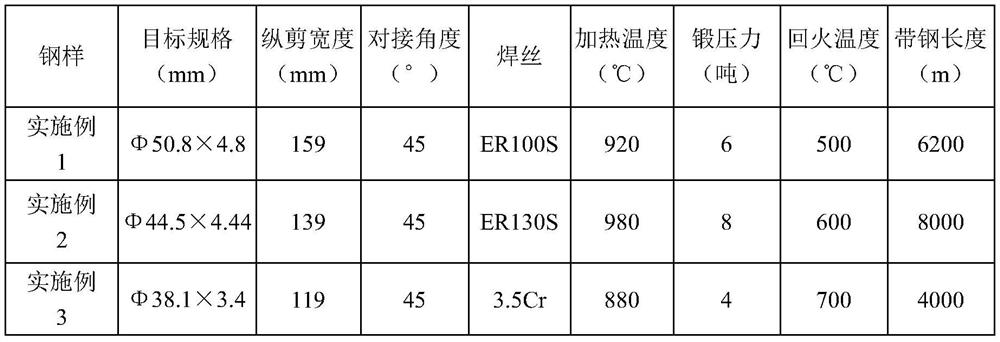

[0061] Embodiment 1, Embodiment 2 and Embodiment 3 were quenched, stress relieved and tempered according to the process shown in Table 5. Specifically take embodiment 1 as an example to illustrate:

[0062] Table 5 Quenching, stress relief and tempering treatment of pipe body

[0063]

[0064] Tube body quenching treatment: The tube blank is rapidly heated at a rate of 20-50°C / s by a composite heating method combining an intermediate frequency heating furnace and a muffle furnace. The heating temperature is A c3 +(30~50)℃, where Ac3=910-203[C%]1 / 2+44.7[Si%]+104[V%]+31.5[Mo%]

[0065] =910-203×0.21 / 2+44.7×0.28+104×0.05+31.5×0.3=846 The final tube heating temperature is 885°C. The heating time is t, t=A×δ=1.5×4.8=7.2≈7min, quenching is carried out after heating, the quenching medium is water, and the quenching termination temperature is room temperature.

[0066] Pipe body stress relief treatment: After drying the surface of the pipe body with cold air, quickly heat it to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com