Lipstick production process

A production process and lipstick technology, which is applied in pharmaceutical formulations, cosmetic preparations, cosmetics, etc., can solve the problems of poor moisturizing and moisturizing properties, dry lips and other problems, and achieve good moisturizing and moisturizing properties, good durability, and production high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

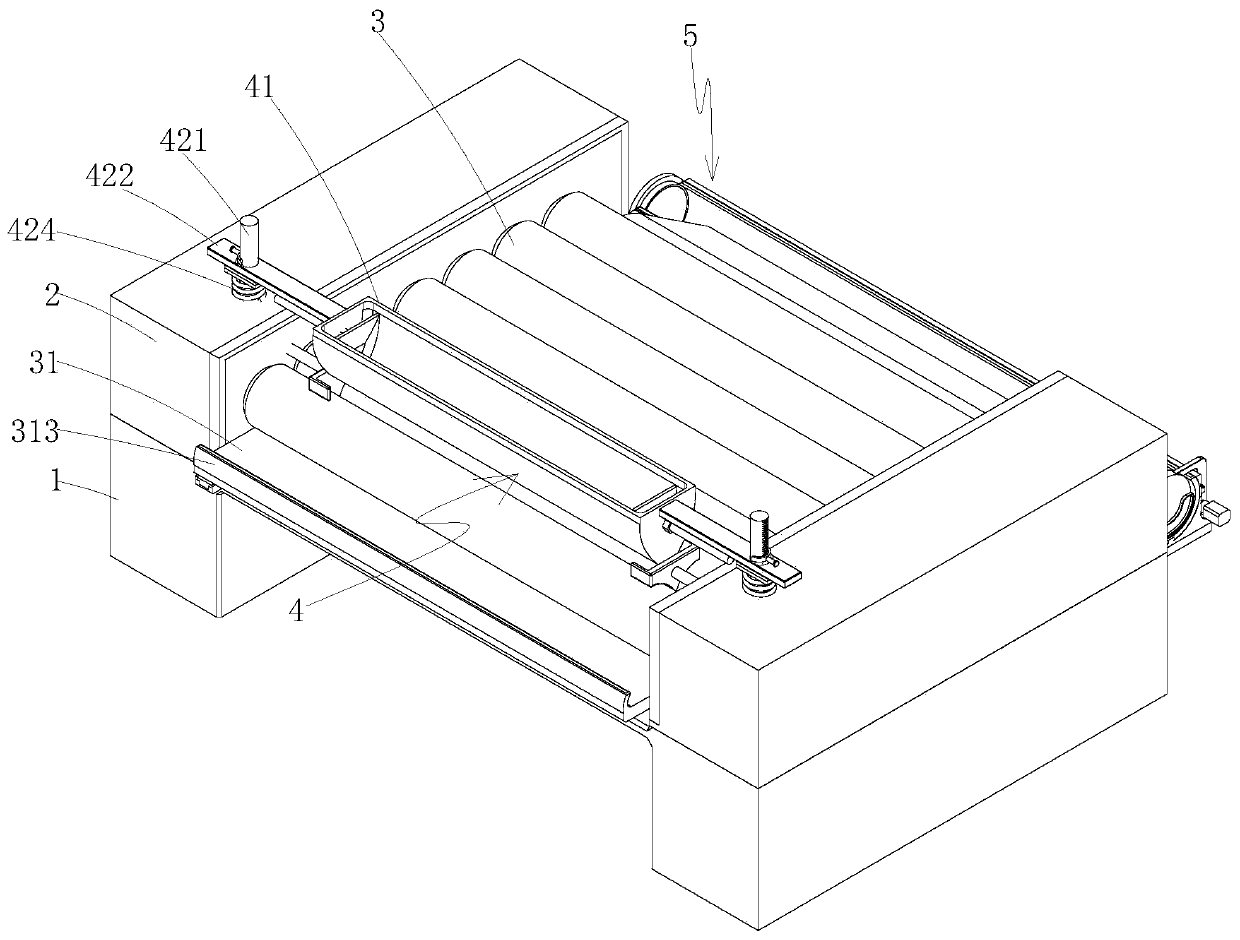

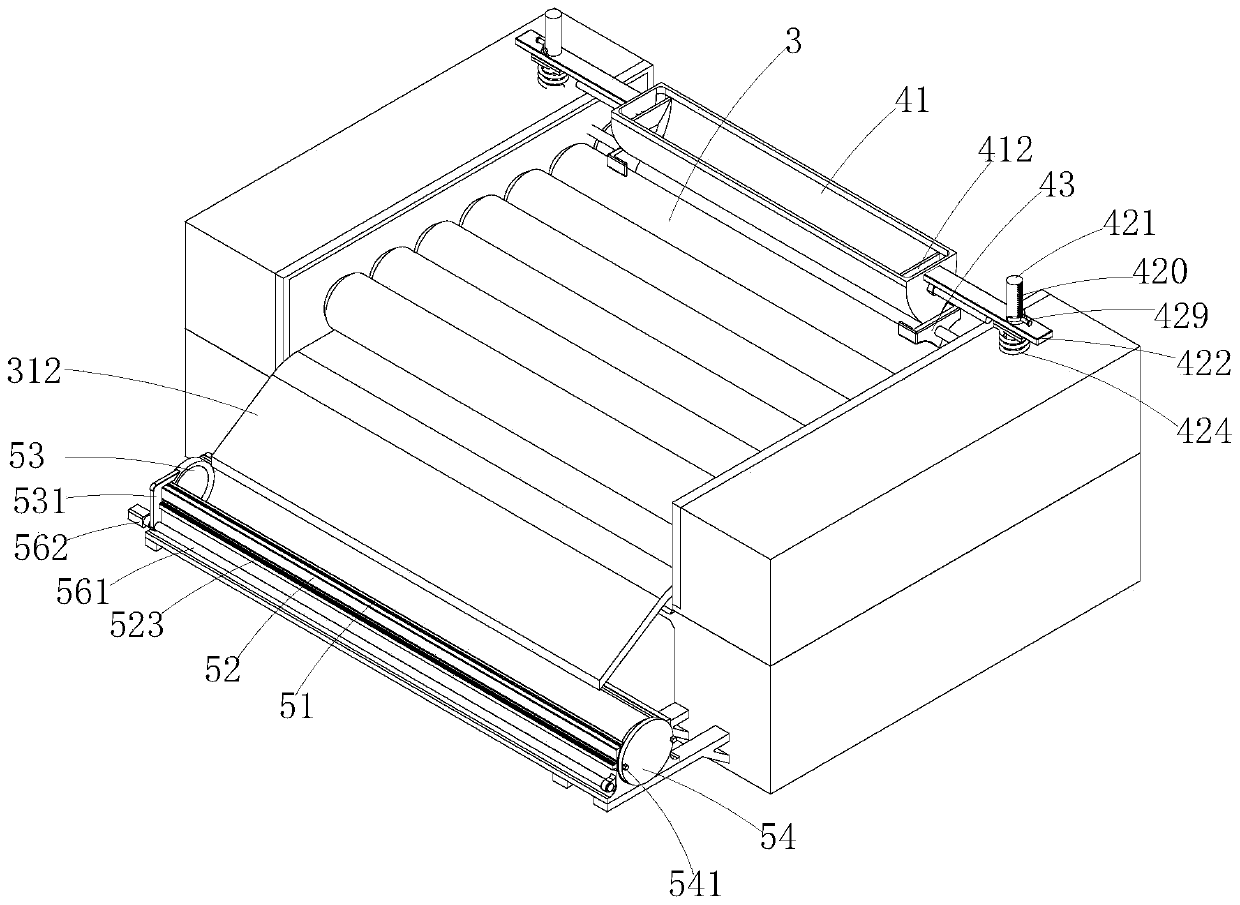

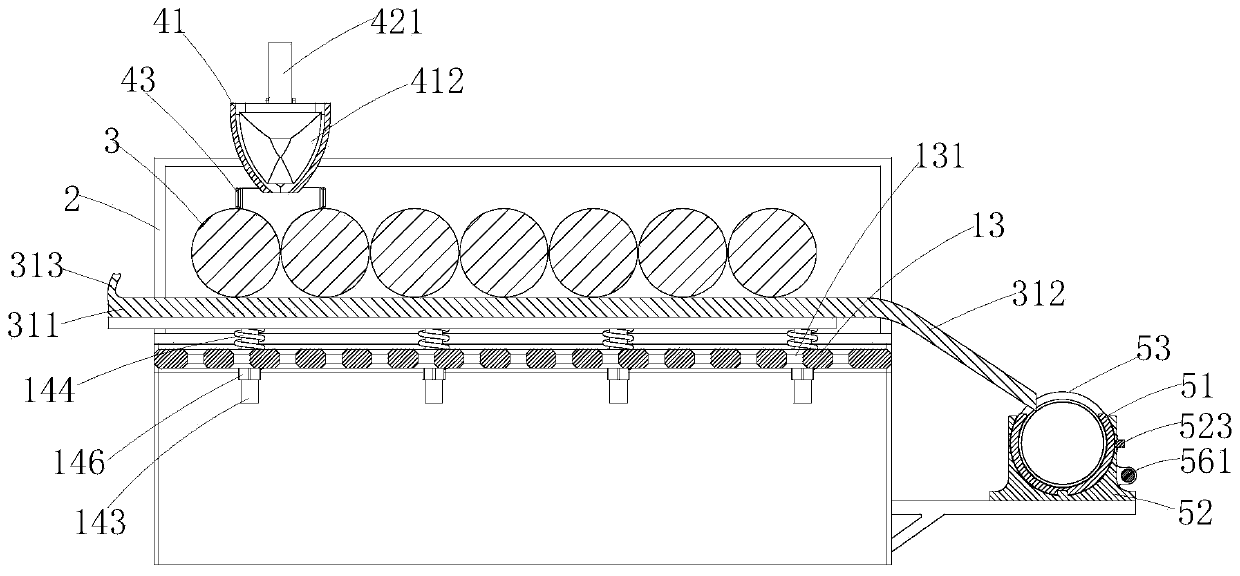

Image

Examples

Embodiment 1

[0037] A lipstick production process, comprising the following components according to weight percentage:

[0038]

[0039] Each of the above groups includes the following processing steps:

[0040] 1) take each component in proportion;

[0041] 2) Add octyldodecanol, polyethylene butylene, dibutyl lauryl glutamine, dibutyl ethyl hexyl glutamine into the stirring tank, and then add tridecyl alcohol Among trimellitic acid esters, heat and stir to obtain a mixed material;

[0042] 3) Pour the mixed material into the grinder for circular grinding, and circulate the grinding four times;

[0043] 4) Heating and melting the beeswax to obtain a beeswax melt, then adding the mixed material into the beeswax melt for stirring, and continuously heating until the material is completely dissolved while stirring, wherein the stirring rate is 50 rpm, and the heating during stirring The temperature is 100°C; a semi-finished product is obtained;

[0044] 5) Wait for the semi-finished pr...

Embodiment 2

[0048] A lipstick production process, comprising the following components according to weight percentage:

[0049]

[0050] Each of the above groups includes the following processing steps:

[0051] 1) take each component in proportion;

[0052] 2) Add octyldodecanol, polyethylene butylene, dibutyl lauryl glutamine, dibutyl ethyl hexyl glutamine into the stirring tank, and then add tridecyl alcohol Among trimellitic acid esters, heat and stir to obtain a mixed material;

[0053] 3) Pour the mixed material into the grinder for circular grinding, and circulate the grinding four times;

[0054] 4) Heat and melt the beeswax to obtain a beeswax melt, then add the mixed material into the beeswax melt for stirring, and continue heating until the material is completely dissolved while stirring, wherein the stirring rate is 50-80 rpm, and when stirring The heating temperature is 100-120°C; semi-finished products are obtained;

[0055] 5) Wait for the semi-finished product to cool ...

Embodiment 3

[0059] A lipstick production process, comprising the following components according to weight percentage:

[0060]

[0061] Each of the above groups includes the following processing steps:

[0062] 1) take each component in proportion;

[0063] 2) Add octyldodecanol, polyethylene butylene, dibutyl lauryl glutamine, dibutyl ethyl hexyl glutamine into the stirring tank, and then add tridecyl alcohol Among trimellitic acid esters, heat and stir to obtain a mixed material;

[0064] 3) Pour the mixed material into the grinder for circular grinding, and circulate the grinding four times;

[0065] 4) Heating and melting the beeswax to obtain a beeswax melt, then adding the mixed material into the beeswax melt for stirring, and continuously heating until the material is completely dissolved while stirring, wherein the stirring rate is 80 rpm, and the heating during stirring The temperature is 120°C; a semi-finished product is obtained;

[0066] 5) Wait for the semi-finished pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com