Method for deodorizing steam condensate of still kettle in production process of calcium silicate board

A technology for steam condensate and production process, which is applied in chemical instruments and methods, neutralization water/sewage treatment, filtration treatment, etc. The effect of easy promotion, simple process flow and mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

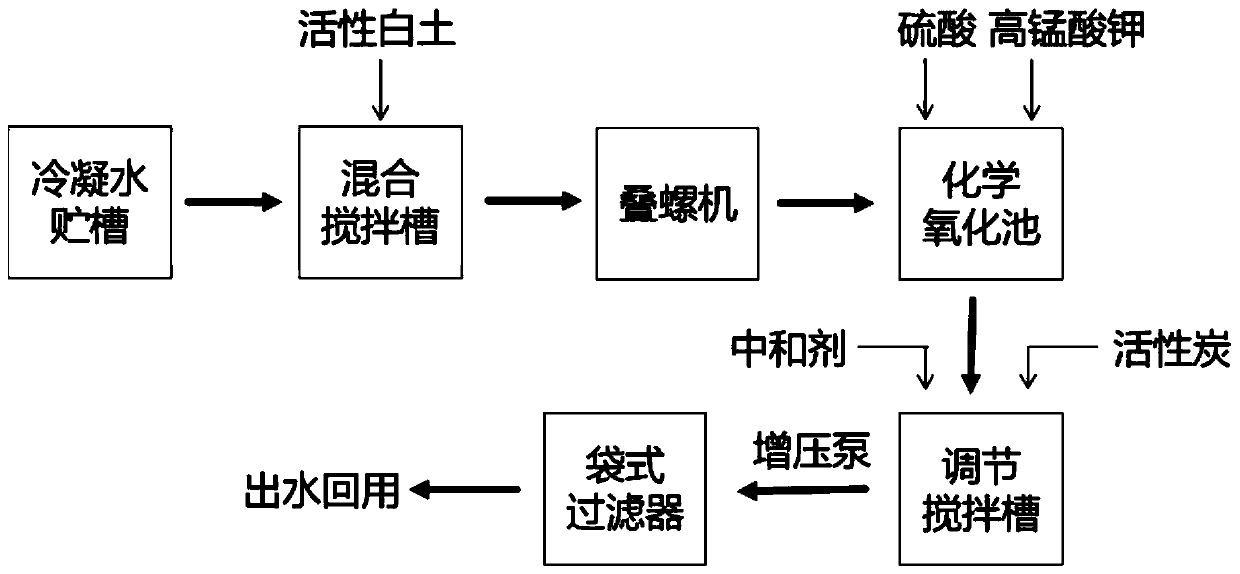

Method used

Image

Examples

Embodiment 1

[0031] The method for deodorizing the steam condensate in the autoclave during the production of the calcium silicate board provided in this embodiment includes:

[0032] S1: Add activated clay in an amount of 20g / L to the steam condensate water to be treated, stir for 75min, and press filter with a screw stacker to obtain filtered water.

[0033] S2: Add sulfuric acid solution with a mass fraction of 65% to the filtered water obtained in step S1, adjust the pH value to 1.85, then add potassium permanganate in an amount of 40 mg / L, stir evenly, and let stand for 24 hours.

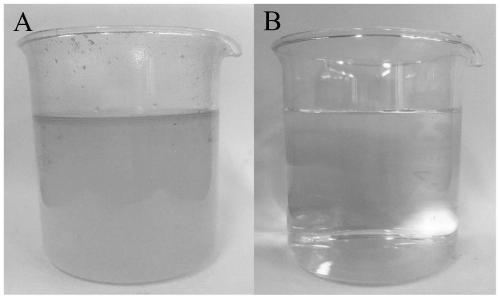

[0034] S3: Under continuous stirring, add 50 mg / L activated carbon to the water obtained in step S2, stir for 120 min, then slowly add barium carbonate, adjust the pH value to 7.75, and then pass through a bag filter (filter precision 1 μm) and a filter element filter (Filtration accuracy 0.45μm) secondary filtration system, the effluent is the water body after treatment, such as figure 2 Shown in B.

Embodiment 2

[0036] The method for deodorizing the steam condensate in the autoclave during the production of the calcium silicate board provided in this embodiment includes:

[0037] S1: Add activated clay in an amount of 13.3g / L to the steam condensate water to be treated, stir for 90min, and press filter with a screw stacker to obtain filtered water.

[0038] S2: Add sulfuric acid solution with a mass fraction of 65% to the filtered water obtained in step S1, adjust the pH value to 2.07, then add potassium permanganate in an amount of 21 mg / L, stir evenly, and let stand for 20 hours.

[0039] S3: under constant stirring, add consumption 30mg / L gac to the water that step S2 obtains, stir 90min, then add barium carbonate, adjust pH value to 7.23, pass through bag filter (filter precision 1 μ m) and filter core filter ( The secondary filtration system with a filtration accuracy of 0.45μm), the effluent is the water after treatment.

Embodiment 3

[0041] The method for deodorizing the steam condensate in the autoclave during the production of the calcium silicate board provided in this embodiment includes:

[0042] S1: Add activated clay in an amount of 5.2g / L to the steam condensed water to be treated, stir for 90min, and press filter with a screw stacker to obtain filtered water.

[0043] S2: Add sulfuric acid solution with a mass fraction of 65% to the filtered water obtained in step S1, adjust the pH value to 2.59, then add potassium permanganate in an amount of 30 mg / L, stir evenly, and let stand for 20 hours.

[0044] S3: Under constant stirring, add 42 mg / L activated carbon to the water obtained in step S2, stir for 90 minutes, then add calcium hydroxide, adjust the pH value to 7.09, and then pass through a bag filter (filter precision 3 μm) and a filter element filter (Filtration accuracy 0.45μm) secondary filtration system, the effluent is the water body after treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com