Polyionic liquid nano hydrogel plugging agent and water-based drilling fluid

A nano-hydrogel, polyionic liquid technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as wellbore instability, and achieve the effect of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

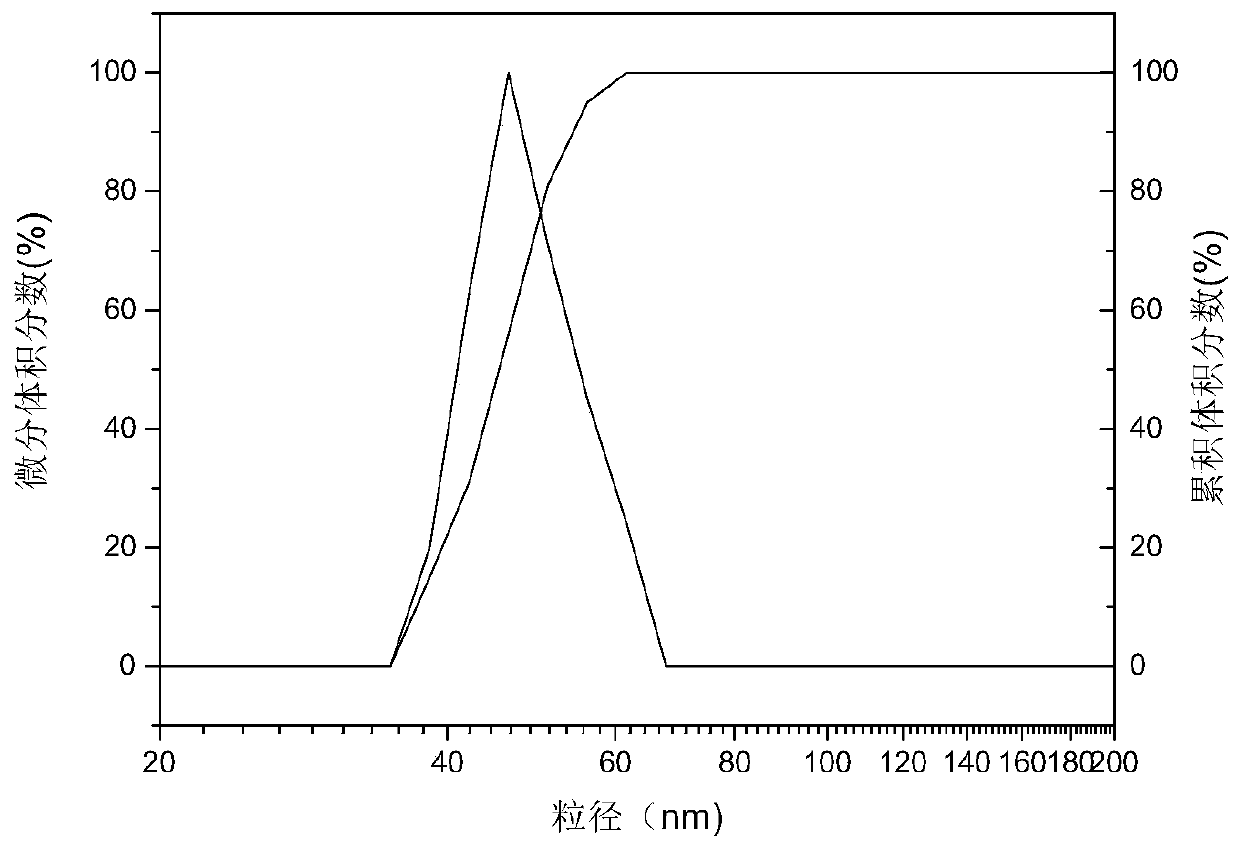

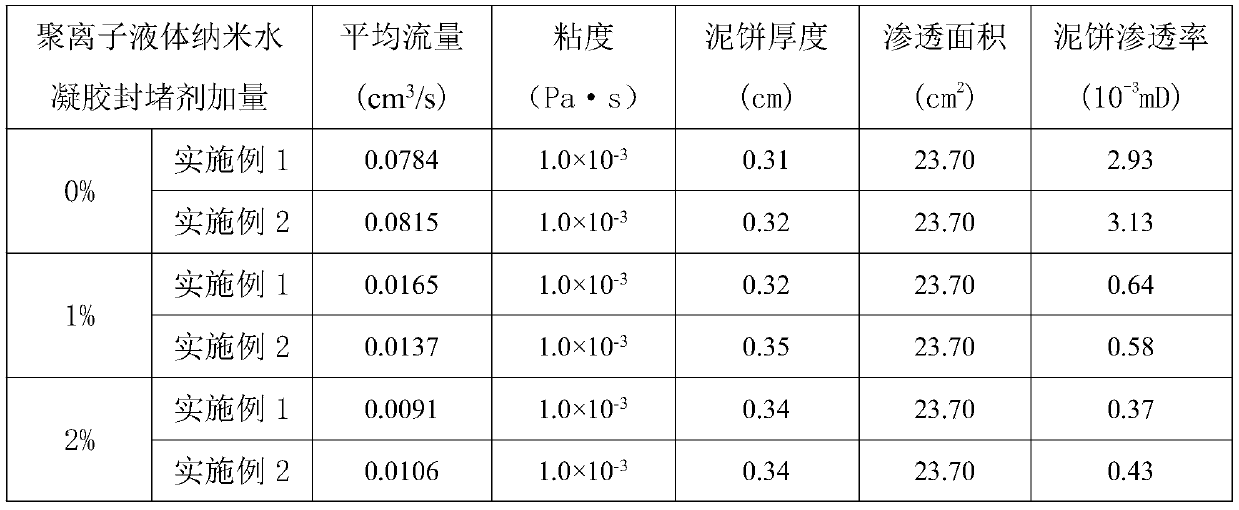

Embodiment 1

[0021] 1. Synthesis of polyionic liquid nano hydrogel plugging agent: add 2.5g of 1-isopropyl-2-methylimidazole and 3.1g of 4-vinylbenzyl chloride into the reactor, and then add 20mL of deionized Water, nitrogen gas was introduced at 25°C to stir the reaction for 6h, after the reaction was completed, it was left to stand for 24h, then washed with 15mL ether to remove impurities, then transferred to a rotary evaporator, and rotated at 25°C for 40min to remove the solvent, Repeated 3 times to obtain 1-isopropyl 3-(4-vinylbenzyl) imidazole chloride;

[0022] Weigh 24g of sodium hydroxide solid and dissolve it in a reaction vessel filled with 120mL of deionized water, then add 28g of acrylic acid to stir and neutralize, so that the neutralization degree of the acrylic acid solution reaches 0.65;

[0023] Add 3.5g of 1-isopropyl 3-(4-vinylbenzyl)imidazole chloride and 0.077g of N,N'-methylenebisacrylamide to the above solution, stir for 40min under nitrogen protection and then plac...

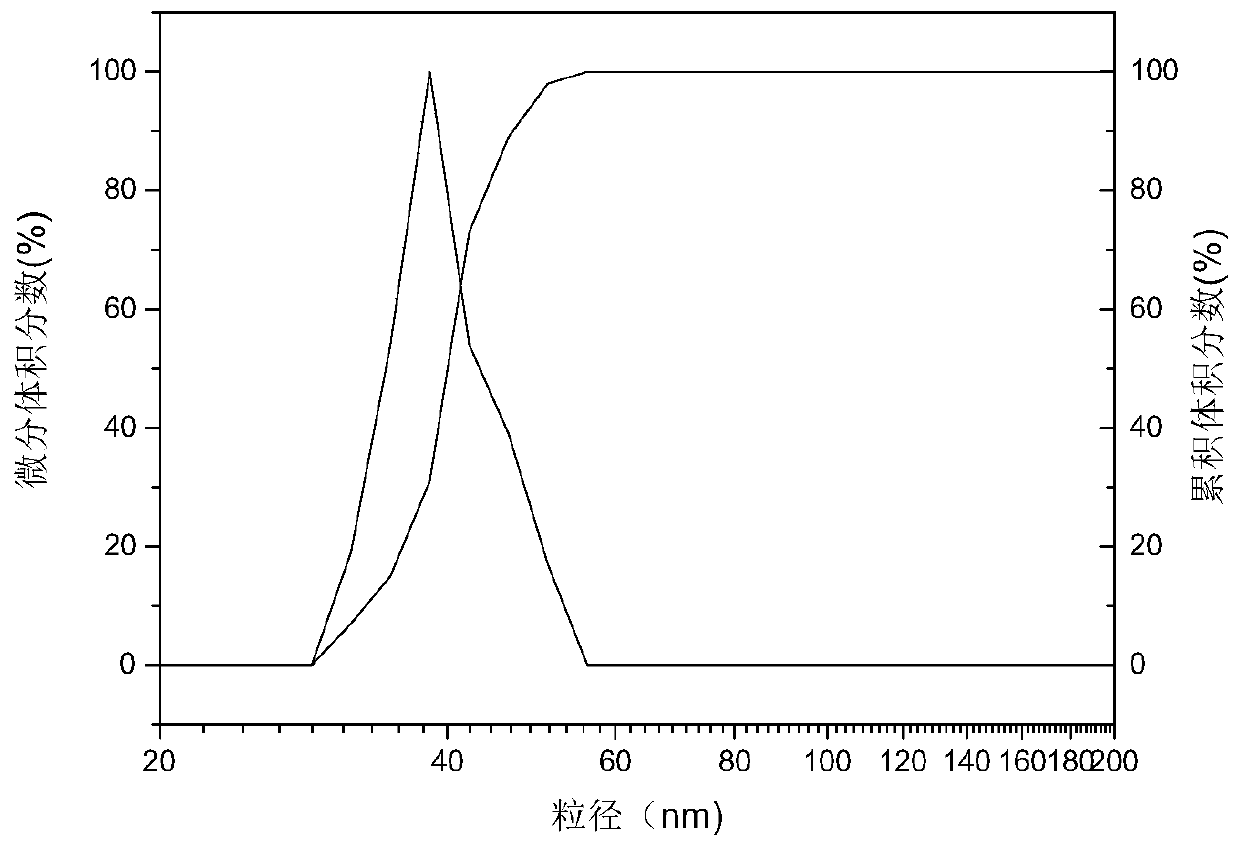

Embodiment 2

[0027] 1. Synthesis of polyionic liquid nano hydrogel plugging agent: add 3.5g of 1-isopropyl-2-methylimidazole and 4.4g of 4-vinylbenzyl chloride into the reactor, and then add 30mL of deionized Water, nitrogen gas was introduced at 30°C to stir the reaction for 8h, after the end of the reaction, it was left to stand for 24h, then washed with 20mL ether to remove impurities, and finally transferred to a rotary evaporator, and rotated at 30°C for 50min to remove Solvent, repeated 3 times to obtain 1-isopropyl 3-(4-vinylbenzyl) imidazole chloride;

[0028] Weigh 20g of sodium hydroxide solid and dissolve it in a reaction vessel filled with 100mL of deionized water, then add 29g of acrylic acid to stir and neutralize, so that the neutralization degree of the acrylic acid solution reaches 0.8;

[0029] Add 4.5g of 1-isopropyl 3-(4-vinylbenzyl)imidazole chloride and 0.12g of N,N'-methylenebisacrylamide to the above solution, stir for 45min under nitrogen protection and then place ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com