High-cleanness composite biodiesel and preparation method thereof

A biodiesel, clean technology, applied in the fields of biofuel, petroleum industry, high-efficiency propulsion technology, etc., can solve the problems of poor low-temperature fluidity of biodiesel, and achieve the effects of improved low-temperature fluidity, efficient and simple preparation process, and favorable promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

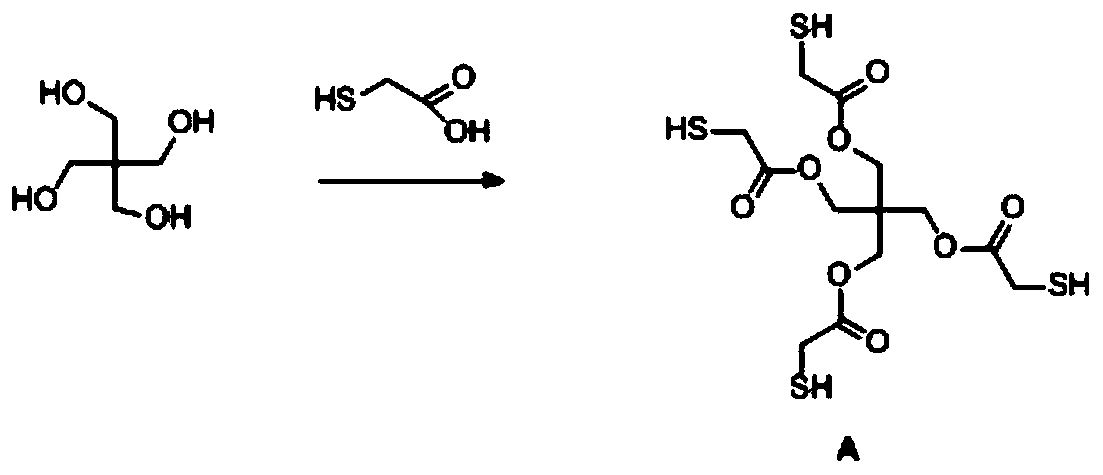

[0029] Step S1: Add 100 parts by weight of thioglycolic acid and 0.4 parts by weight of p-toluenesulfonic acid to the reaction vessel, and add THF to the reaction vessel at a ratio of 10 mL of tetrahydrofuran per gram of thioglycolic acid, and continuously feed nitrogen into the solution. The amount of adding 3mL tetrahydrofuran to 1 gram of pentaerythritol was uniformly miscible with 37 parts by weight of pentaerythritol and THF. Under the condition of the reaction temperature of 100°C, the THF solution of pentaerythritol was slowly added dropwise to the reaction vessel and stirred evenly. After 6 hours, the reaction was stopped and cooled. , Precipitate after rotary evaporation and concentration, filter and further wash and dry to obtain product A pentaerythritol mercaptoacetate;

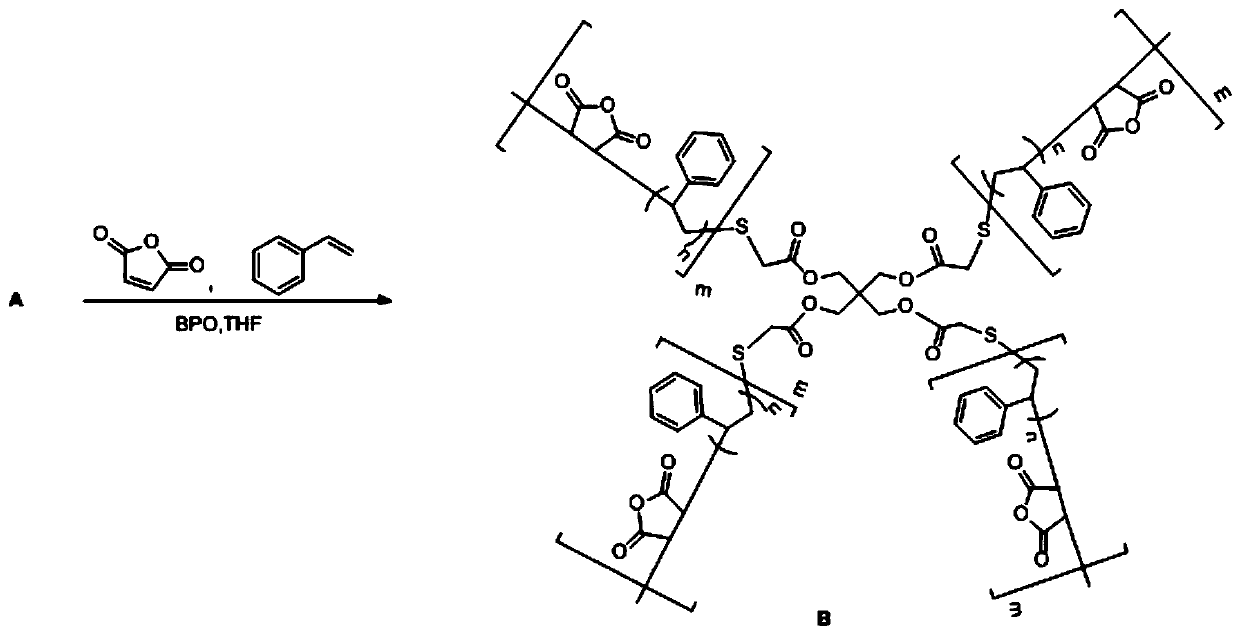

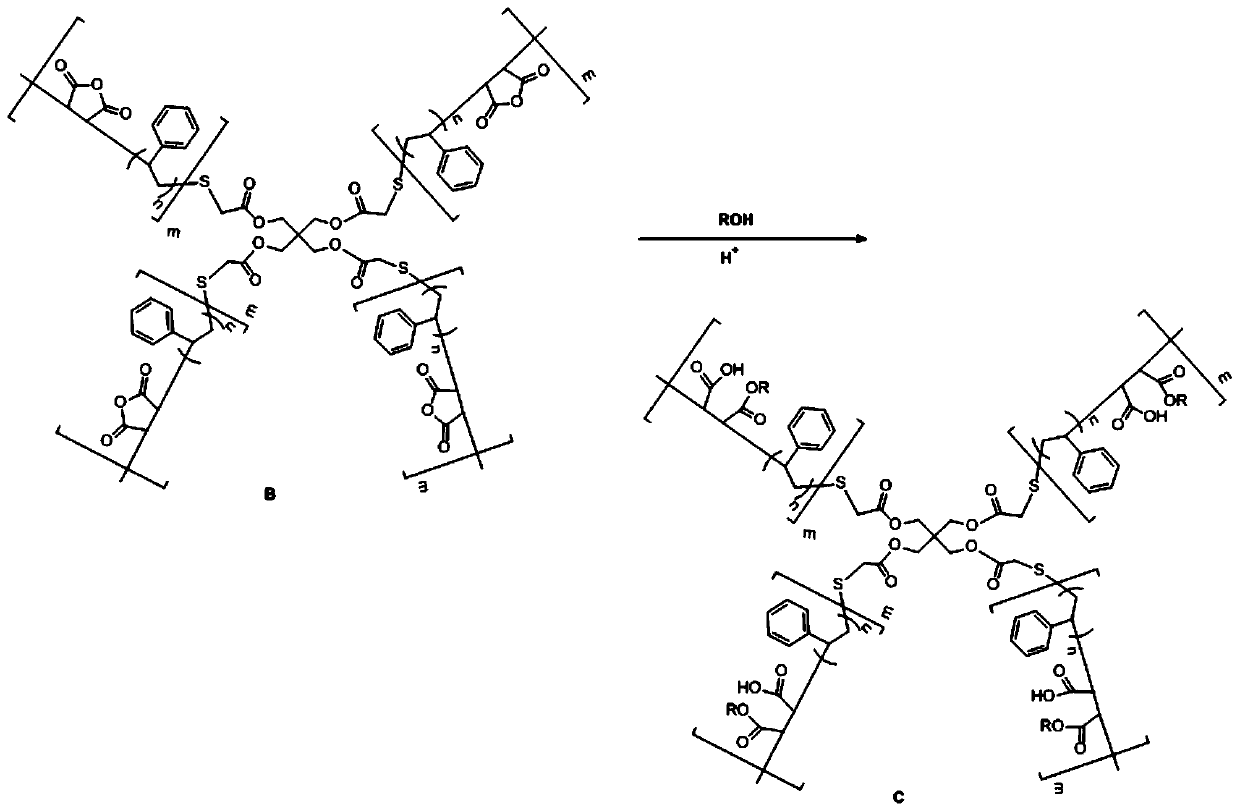

[0030] Step S2: Add 100 parts by weight of maleic anhydride to the reaction container, and add 10 mL of toluene per gram of maleic anhydride. For liquid B, 143 parts by weight of styrene, 43 parts...

Embodiment 2

[0035] Step S1: Add 100 parts by weight of thioglycolic acid and 0.5 parts by weight of p-toluenesulfonic acid to the reaction vessel, and add THF to the reaction vessel at a ratio of 11 mL of tetrahydrofuran per gram of thioglycolic acid, and continuously feed nitrogen into the solution. The dosage of adding 4mL tetrahydrofuran to 1 gram of pentaerythritol was uniformly miscible with 38.5 parts by weight of pentaerythritol and THF. Under the condition of reaction temperature of 100°C, the THF solution of pentaerythritol was slowly added dropwise to the reaction vessel and stirred evenly. After 7 hours, the reaction was stopped and cooled. , Precipitate after rotary evaporation and concentration, filter and further wash and dry to obtain product A pentaerythritol mercaptoacetate;

[0036] Step S2: Add 100 parts by weight of maleic anhydride to the reaction container, and add 11 mL of toluene per gram of maleic anhydride. For liquid B, 146.5 parts by weight of styrene, 44.5 par...

Embodiment 3

[0042] Step S1: Add 100 parts by weight of thioglycolic acid and 0.6 parts by weight of p-toluenesulfonic acid to the reaction vessel, and add THF to the reaction vessel at a ratio of 12 mL of tetrahydrofuran per gram of thioglycolic acid, and continuously feed nitrogen into the solution. 40 parts by weight of pentaerythritol and THF are homogeneously miscible. Under the condition of reaction temperature of 100°C, slowly drop the THF solution of pentaerythritol into the reaction vessel and stir evenly. After 8 hours, stop the reaction and cool , Precipitate after rotary evaporation and concentration, filter and further wash and dry to obtain product A pentaerythritol mercaptoacetate;

[0043] Step S2: Add 100 parts by weight of maleic anhydride to the reaction container, and add 12 mL of toluene per gram of maleic anhydride. For liquid B, 150 parts by weight of styrene, 46 parts by weight of dibenzoyl peroxide, and 3 parts by weight of product A are dissolved in toluene. The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com