A preparation method of aluminum alloy extruded material for subway rigid suspension busbar

A technology of aluminum alloy and extruded material, which is applied in the field of preparation of aluminum alloy extruded material, can solve problems such as insufficient corrosion resistance of aluminum alloy extruded material, achieve excellent mechanical properties, prolong service life, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

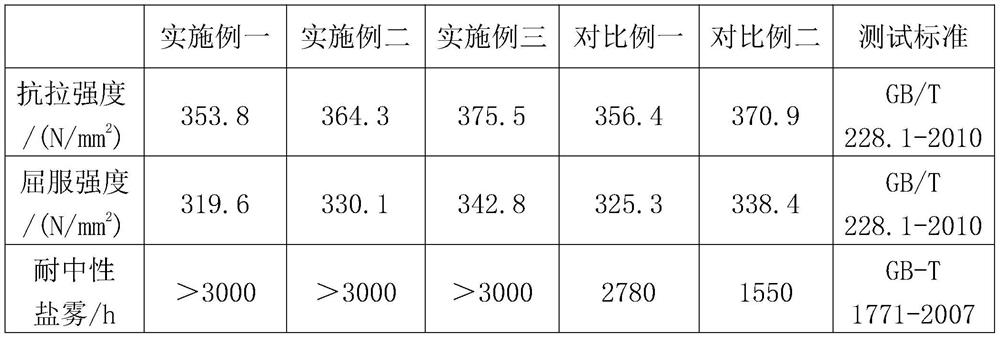

Examples

Embodiment 1

[0024] A method for preparing an aluminum alloy extruded material used for subway rigid suspension busbars, the mass fractions of the elements in the aluminum alloy extruded material are respectively: 0.65% Mg, 0.6% Si, 0.15% Zn, 0.03% Fe , 0.06% Cu, 0.06% Mn, 0.02% Cr, 0.01% Zr, 0.02% La, 0.03% Sc, 0.015% Y, and the balance is Al. The preparation method comprises the following steps:

[0025] (1) Melting and casting: heat up the melting furnace to 725°C, add aluminum ingots and fast-melting silicon, stir and remove slag, add other components after the aluminum ingots are completely melted, and pass nitrogen and refining agents for refining after all the furnace materials are melted , refined for 25 minutes, and sampled and analyzed after slag removal, if the composition is qualified, then stand for 30 minutes, then cast into aluminum rods, and then homogenize the cast rods for 15 hours, and the temperature is controlled at 515°C; if the composition is unqualified , continue t...

Embodiment 2

[0031] A method for preparing an aluminum alloy extruded material used for subway rigid suspension busbars, the mass fractions of each element in the aluminum alloy extruded material are: 0.7% Mg, 0.7% Si, 0.1% Zn, 0.04% Fe , 0.07% Cu, 0.05% Mn, 0.01% Cr, 0.03% Zr, 0.04% La, 0.02% Sc, 0.025% Y, and the balance is Al. The preparation method comprises the following steps:

[0032] (1) Melting and casting: heat up the melting furnace to 735°C, add aluminum ingots and fast-melting silicon, stir and remove slag, add other components after the aluminum ingots are completely melted, and pass nitrogen and refining agents for refining after all the furnace materials are melted , refined for 28 minutes, and sampled and analyzed after slag removal, if the composition is qualified, then stand for 35 minutes, then cast into aluminum rods, and then homogenize the cast rods after casting for 12 hours, and the temperature is controlled at 525°C; if the composition is unqualified , continue to...

Embodiment 3

[0038] A method for preparing an aluminum alloy extruded material used for subway rigid suspension bus bars, the mass fractions of the elements in the aluminum alloy extruded material are respectively: 0.8% Mg, 0.75% Si, 0.12% Zn, 0.02% Fe , 0.08% Cu, 0.04% Mn, 0.03% Cr, 0.02% Zr, 0.03% La, 0.01% Sc, 0.02% Y, and the balance is Al. The preparation method comprises the following steps:

[0039] (1) Melting and casting: heat up the melting furnace to 745°C, add aluminum ingots and fast-melting silicon, stir and remove slag, add other components after the aluminum ingots are completely melted, and pass nitrogen and refining agents for refining after the furnace materials are completely melted , refined for 30 minutes, and sampled and analyzed after slag removal, if the composition is qualified, then stand for 40 minutes, then cast into aluminum rods, and then homogenize the cast rods for 10 hours, and the temperature is controlled at 535 °C; if the composition is unqualified , co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com