Extraction method and extraction equipment for farmland soil microplastics

An extraction method and technology for microplastics, which are used in the preparation, sampling, and analysis of materials for testing, and can solve problems that are not conducive to the true and accurate assessment of microplastic health risks, the interference of microplastic abundance and species, and the influence of microplastic properties. Larger problems, to achieve the effect of reducing loss, accurate experiment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Preparation of microplastic standard products: Take the agricultural mulch film purchased from the farm tool market and cut it. After cutting, pass through 40 mesh, 20 mesh, and 10 mesh sieves in turn to obtain microplastic standard products with particle sizes of 0.45mm, 1mm, and 2mm. .

[0055] (2) Sample collection: According to the "Technical Specifications for Soil Environment Monitoring" (HJ / T166-2004) and "Technical Specifications for Farmland Soil Environmental Quality Monitoring" (NY / T395-2012), the sampling points are reasonably arranged, and the five-point method is used to collect farmland soil samples;

[0056] (3) Pretreatment: Air-dry the soil sample collected in step (2) after removing foreign matter, and the dried soil sample is ground through a 20-mesh sieve to obtain a pretreatment sample;

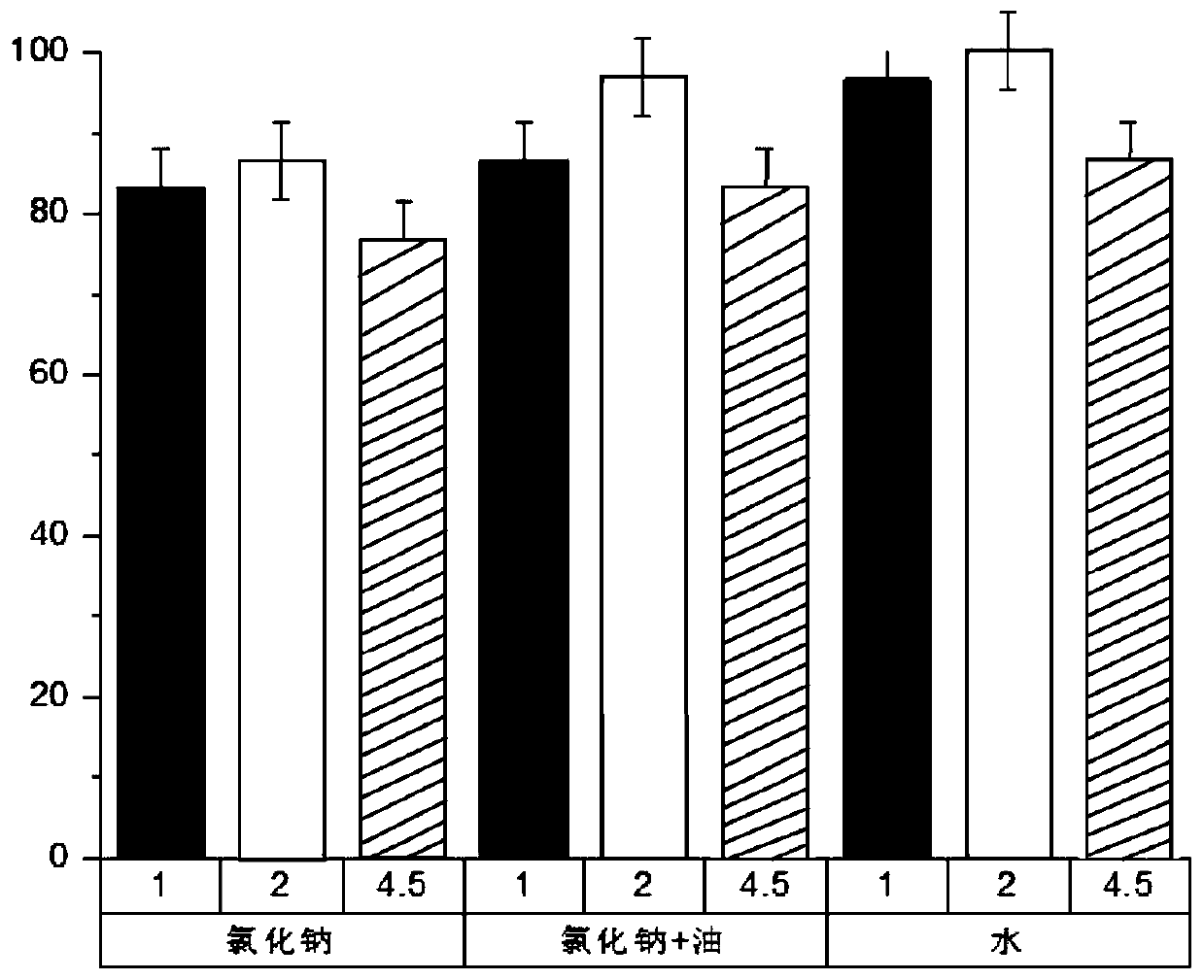

[0057] (4) Flotation: Weigh 100g of the pretreated soil sample obtained in step (3), transfer it to a beaker, add 10 microplastic standard items with a parti...

Embodiment 2

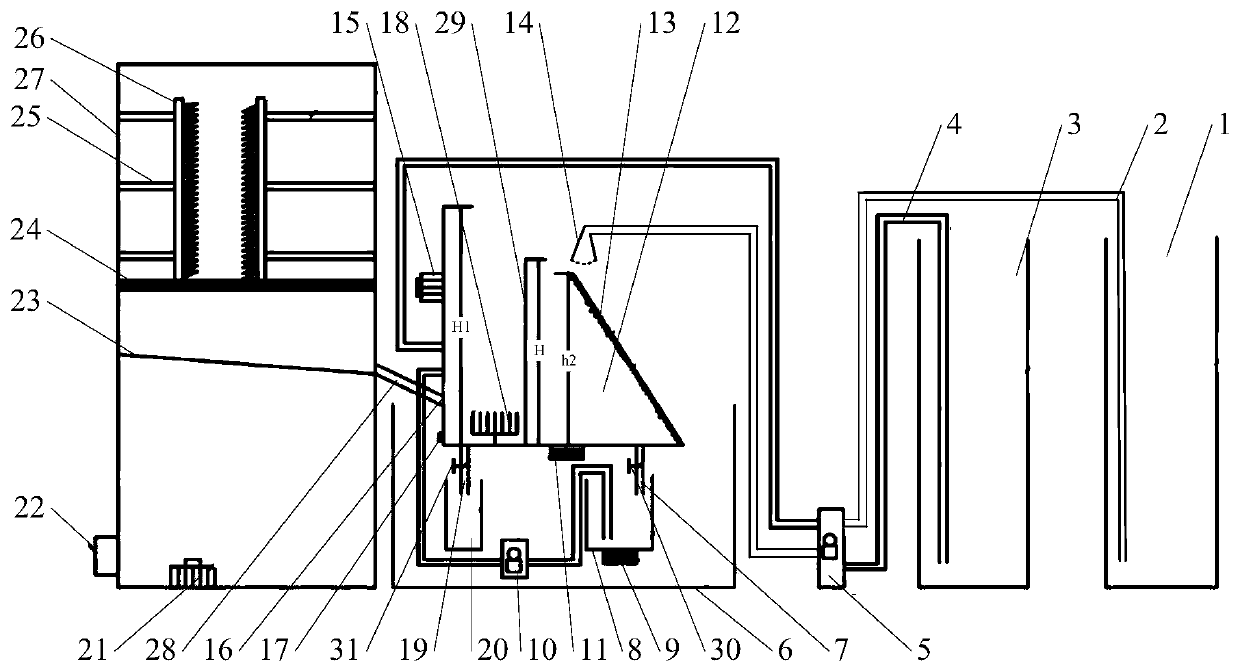

[0119] The casing (27) is arranged directly above the sample storage tank (23). A grinder (26) is arranged in the casing (27), and the grinder (26) is controlled by a motor B (21) at the bottom of the sample storage tank (23) through a telescopic rod (25).

[0120] The crushing and screening layer (24) is double-layered, and the sequence is stainless steel plate-sieve mesh, and is controlled by the control panel at the bottom of the sample storage tank (23). Set the time on the control panel, for example, sieve once every 15 minutes, then within 15 minutes, the mill (26) drives the telescopic rod (25) to work through the motor B (21), and the crushing and screening layer (24) is still stainless steel Plate-sieve cloth; After 15 minutes, motor B (21) stopped supplying power to the mill (26), the mill (26) stopped working, and the stainless steel plate in the broken sieving layer (24) moved slowly to one side, The sieve does not move, so as to achieve the purpose of sieving.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com