Contactless Slingshot Gearbox

A non-contact, gearbox technology, applied in the field of gearboxes, can solve the problems of large operating loss of clutches and gears, difficulty in taking into account speed changes, and aggravating the burden of high speeds, etc., to achieve the effects of low cost, weight reduction, and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

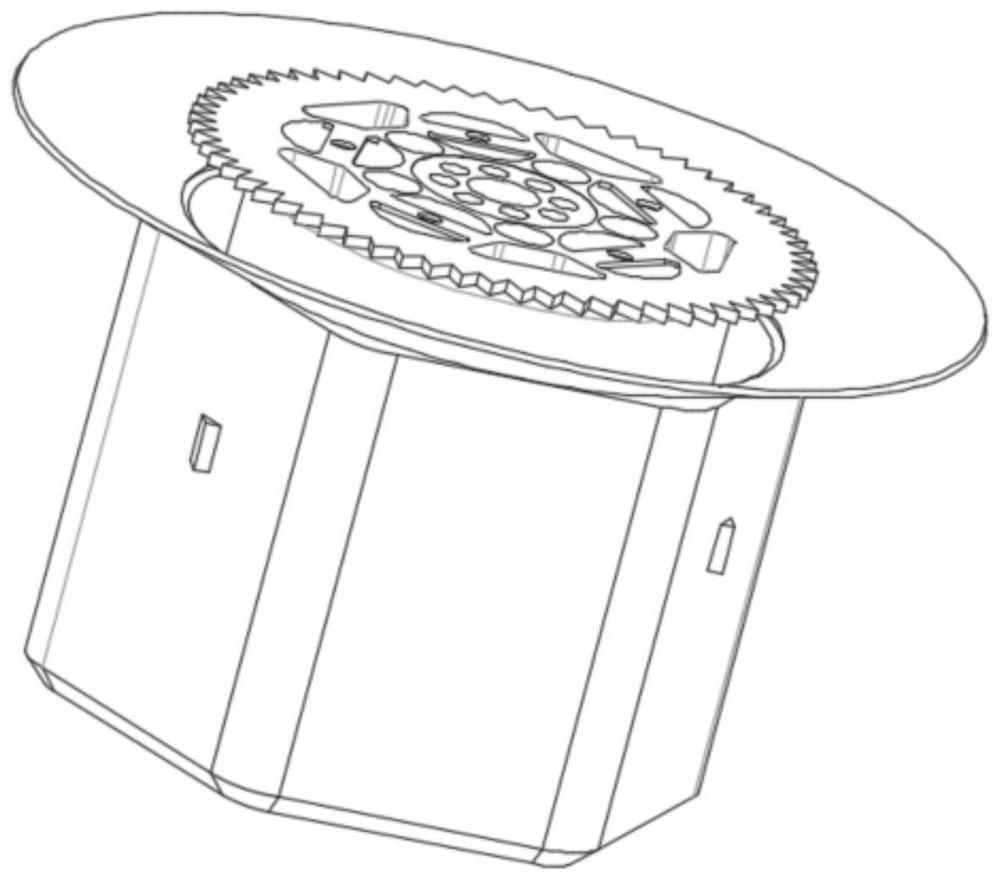

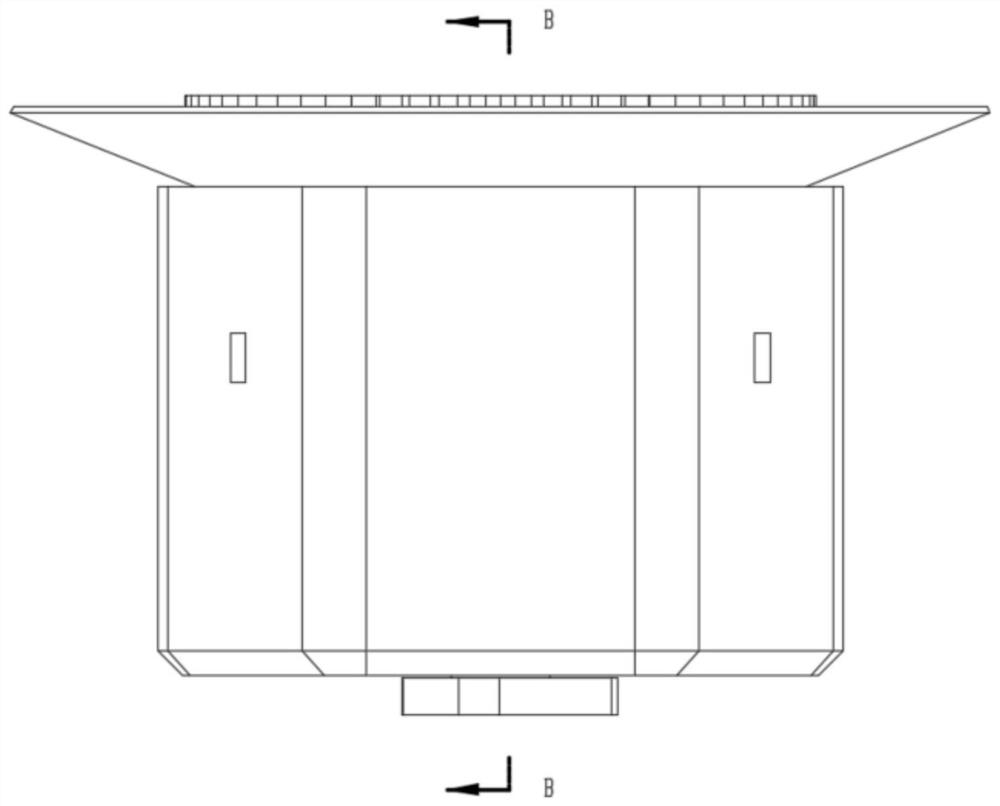

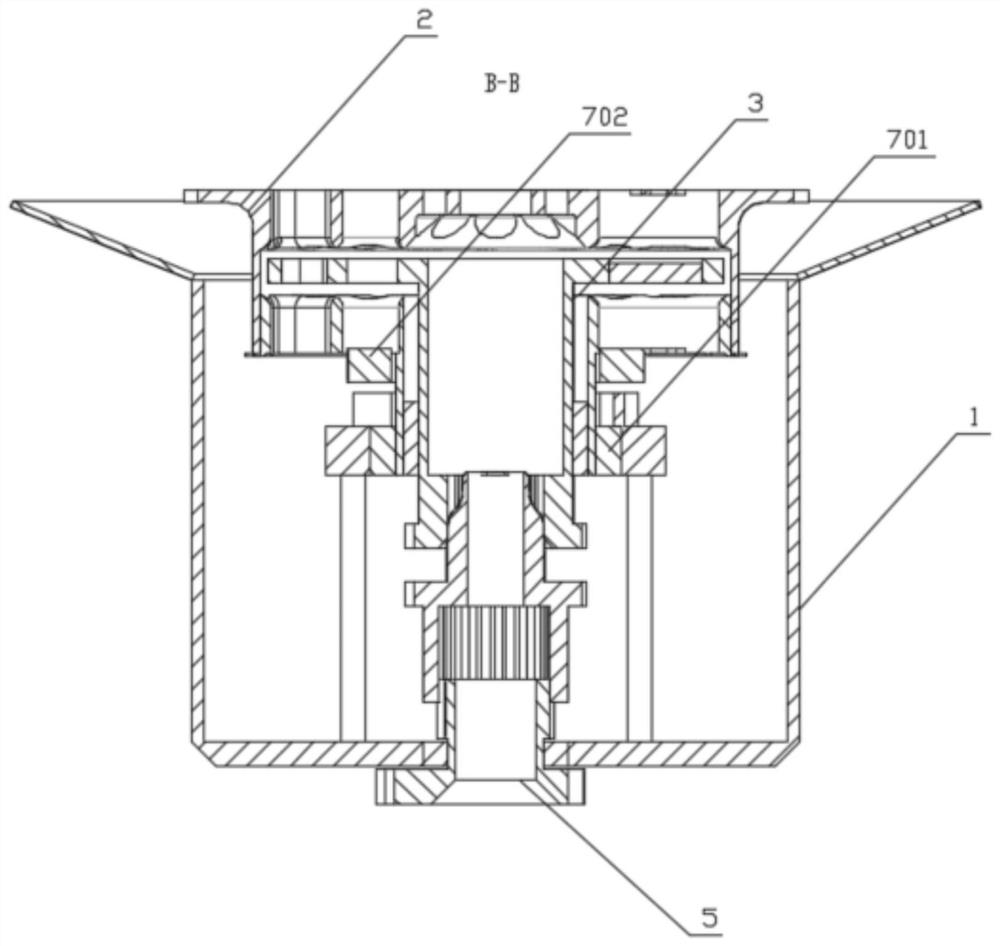

[0045] refer to Figure 1-6 , a non-contact slingshot gearbox, including a housing 1, the casing 1 is provided with a power input end 2 and a power output end 5, and the gearbox includes:

[0046] Several electromagnets 6 are arranged on the power input end 2, and the electromagnet used in the present embodiment is a DC sucker type electromagnet 5030 (commercially available);

[0047] A power supply system, electrically connected to the plurality of electromagnets 6, for supplying power to the plurality of electromagnets 6;

[0048] The magnetic part 4 is used to attract each other with the electromagnet 6 when energized, and the magnetic part 4 includes a silicon steel sheet;

[0049] Output disc 3, the output disc 3 is provided with the magnetic part 4, the output disc 3 is correspondingly arranged inside the input end 2, the output disc 3 is connected to the output end 5, the output disc 3 is used to receive the magnetic field of the electromagnet 6 and follow the rotatio...

Embodiment 2

[0060] This embodiment is basically the same as Embodiment 1, the difference lies in:

[0061] The electromagnet installation groove of the outer input disk 201 and the electromagnet installation groove of the inner input disk 202 are arranged in a misaligned manner.

Embodiment 3

[0063] Use of a contactless slingshot gearbox as an induction motor.

[0064] When the stator 701 conducts alternating current, the frequency and voltage of the alternating current are adjusted, and the rotor 702 and the stator 701 form an induction motor.

[0065] working principle:

[0066] The traditional induction motor uses the principle of electromagnetic induction to generate a rotating magnetic field through the stator current, and interacts with the induced current in the rotor winding to generate electromagnetic torque for energy conversion. In a traditional induction motor, the rotor is inside the stator. In this embodiment, refer to image 3 , the rotor 702 is under the stator 701, the stator 701 generates a changing magnetic field under the drive of alternating current, the rotor 702 cuts the changing magnetic field to generate a changing current, and the changing current inside the rotor 702 further generates a changing magnetic field, the magnetic field of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com