Preparation method of grass carp fish scale gelatin hydrolysate antifreeze agent

A technology of fish scale gelatin and hydrolyzate, which is applied in the direction of freezing/cooling to preserve meat/fish, etc., can solve the problem that fish scales cannot be fully utilized, and achieve the effects of increasing economic added value, prolonging storage time, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of grass carp fish scale gelatin hydrolyzate antifreeze agent, comprising the following steps:

[0027] (1) Pretreatment: Soak the dried fish scales in a small amount of deionized water, mash them with a wet method to remove the silvery substance on the surface of the fish scales, wash and drain to obtain material A;

[0028] (2) Decalcification: add food-grade citric acid solution with a mass fraction of 4% to material A, stir for 2 hours to decalcify, then rinse with water until the pH reaches 7.0, and drain to obtain material B;

[0029] (3) Gelatin extraction: add deionized water to material B, use 0.5% hydrochloric acid to adjust the pH to 5, extract at 50°C for 4 hours, filter with gauze and freeze-dry to obtain sample C;

[0030] (4) Enzymolysis: add 1% flavored protease aqueous solution to sample C, adjust the pH to 6 with sodium hydroxide, stir and heat in a water bath at 50°C for 4 hours, and boil for 10 minutes to inactivate the enzyme; ...

Embodiment 2

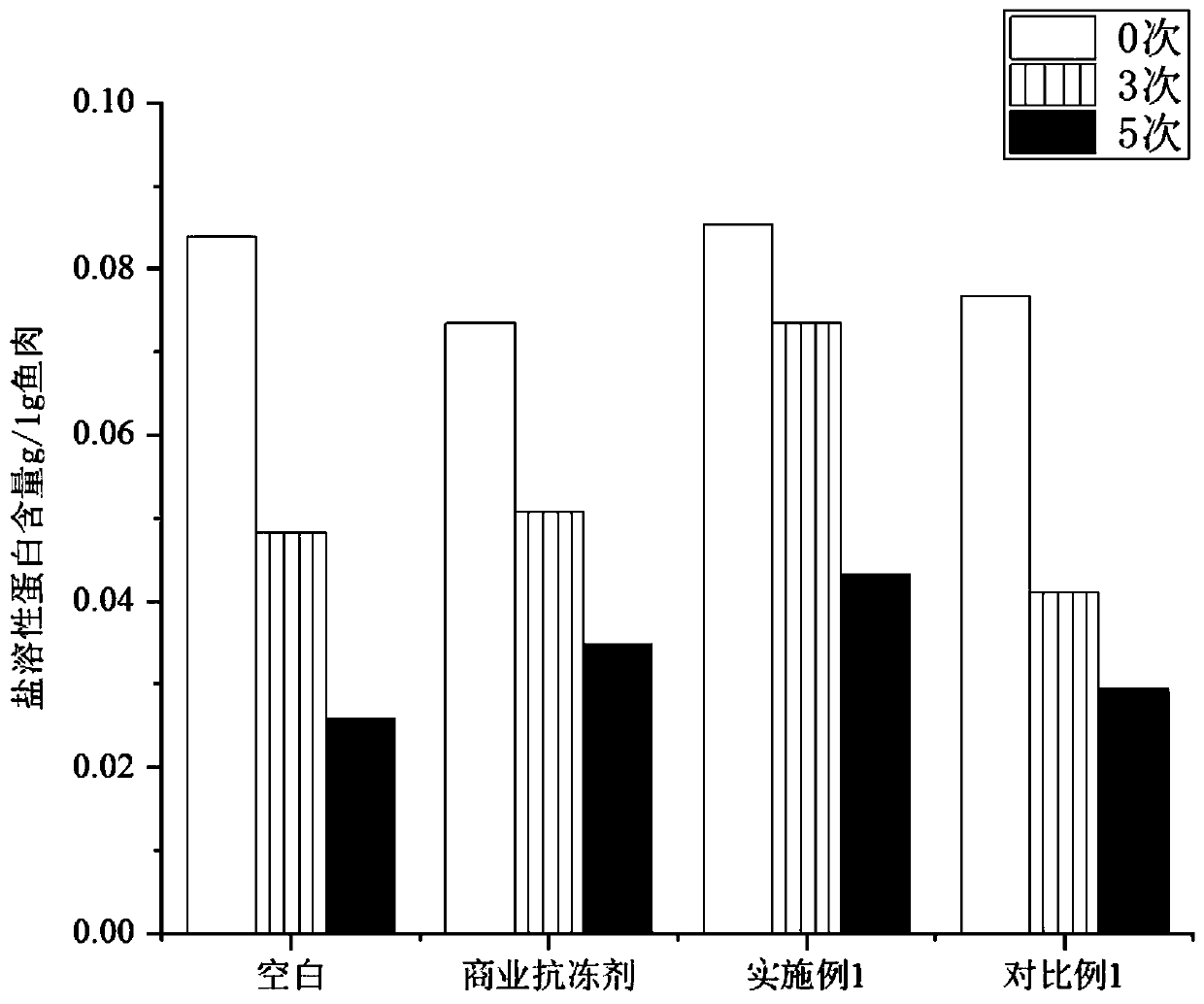

[0042] The fresh grass carp is killed by the same treatment method and transported back to the laboratory within 30 minutes. After washing, take the white meat part, grind it with a meat grinder, rinse it twice, wring out the water with gauze, and apply 8% (w / w) The antifreeze agents prepared in Example 1 and Comparative Example 1 were respectively added to the fish meat, stirred evenly with a disposable spoon, subpacked at 2 g per bag, and then subjected to low-temperature freeze-thaw treatment (stored at -20°C for 20 hours, stored at 4°C for 4 hours), added to commercial The samples of antifreeze (4% sucrose, 4% sorbitol) and the samples without antifreeze were used as comparison. The samples that were frozen and thawed 0, 3, and 5 times were taken respectively, and the content of salt-soluble protein was determined, and the results were as follows: figure 1 shown.

[0043] figure 1 It reflects the change of salt-soluble protein content of grass carp meat in the process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com