Double-fermentation drinking type yoghourt and preparation method thereof

A drinking-type, double-fermentation technology, applied in the direction of bacteria and applications used in milk preparations and food preparation, can solve the problems of single nutrient composition, general flavor, difficult to meet the nutrient-rich needs of healthy food, etc., to improve fat Excessive, reducing the incidence of diseases, beneficial to the health of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

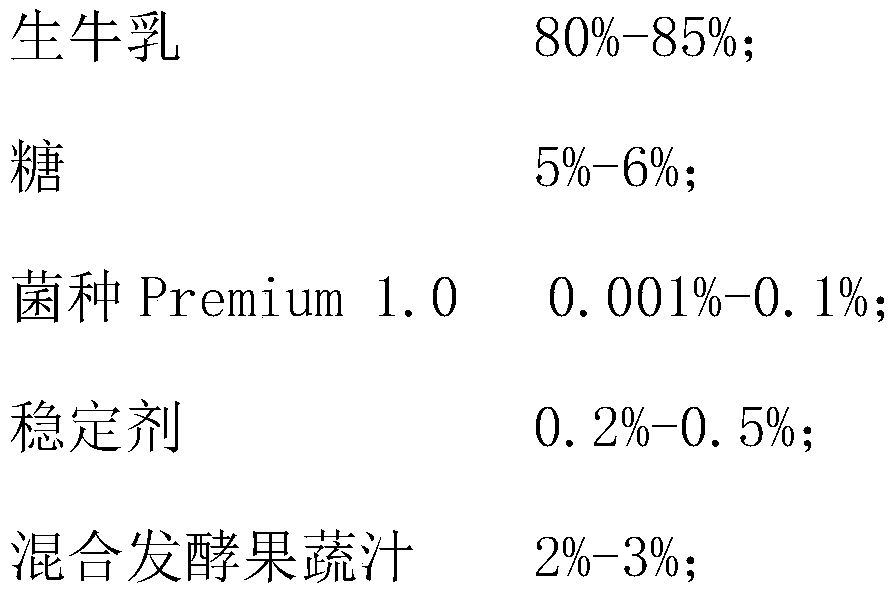

[0072] A double fermented drinking yogurt comprising the following ingredients:

[0073] Raw milk, sugar, strain Premium 1.0, stabilizer, mixed fermented fruit and vegetable juice, water.

[0074] In embodiments 1-4, white granulated sugar is used as sugar, and sucrose, fructose, etc. can also be used in other embodiments.

[0075] In Examples 1-4, pectin is used as the stabilizer, and modified starch E1442, modified starch E1414, etc. can also be used in other embodiments.

[0076] In embodiment 1-4, mixed fermented fruit and vegetable juice is formed by compound fermentation of carrot juice, papaya juice, mango juice, tomato juice, apple juice, can also adopt carrot juice, papaya juice, mango juice, Tomato juice, apple juice and other vegetable juices and fruit juices are compounded and fermented by one or more kinds.

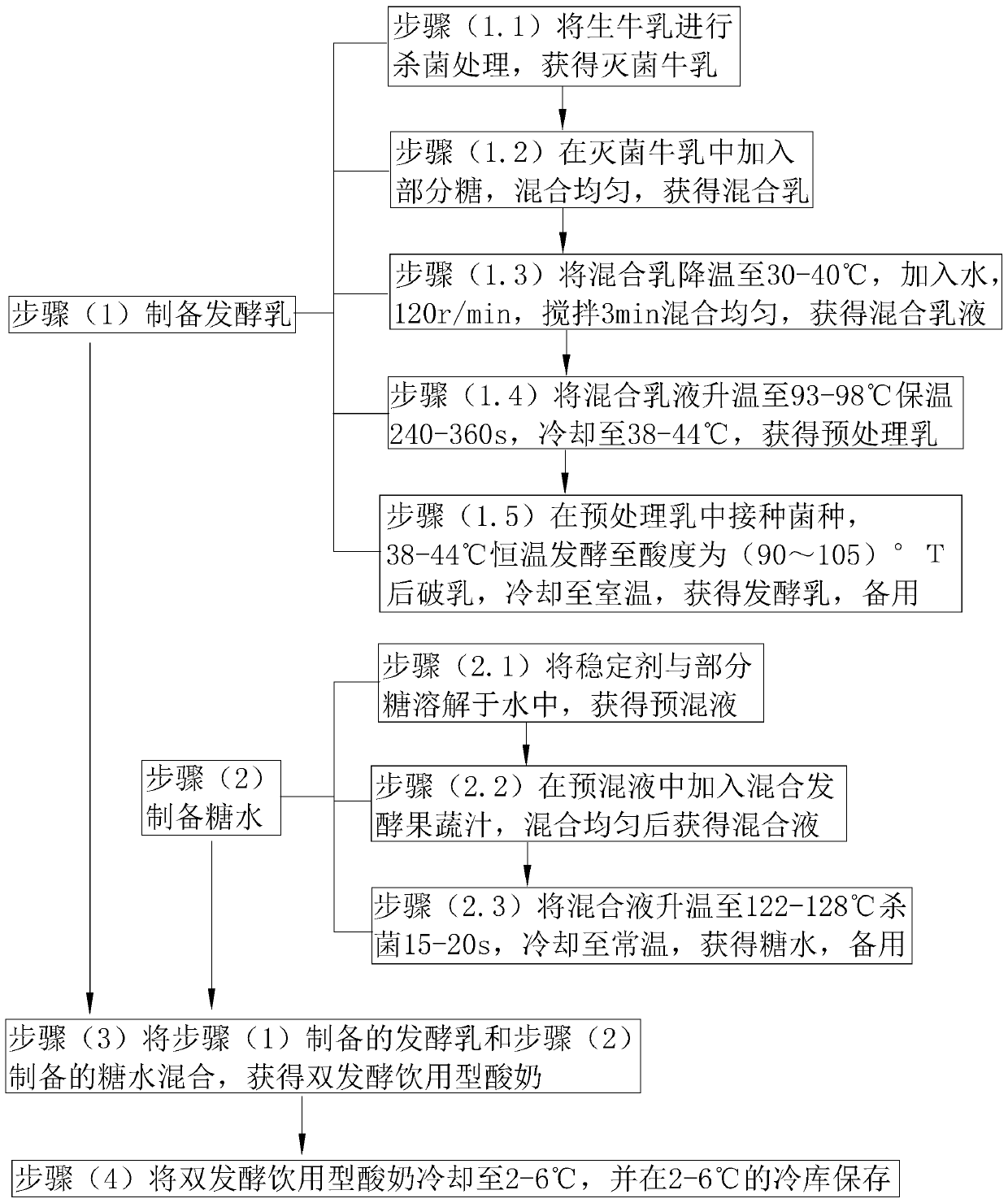

[0077] refer to figure 1 , is the preparation method of the double-fermented drinking yoghurt of embodiment 1-4, specifically comprises the following step...

Embodiment 5

[0096] Compared with embodiment 4, the difference only lies in:

[0097] Step (1.1) The raw milk sterilization temperature is 80°C;

[0098] Step (1.3) Cool down the mixed milk to 30°C and then add water;

[0099] Step (1.4) heating the mixed emulsion to 93°C for 360s, cooling to 38°C to obtain pretreated milk;

[0100] Step (1.5) inoculate the strain Premium 1.0 in the pretreated milk, ferment at a constant temperature at 38°C until the acidity is 90°T, and then break the emulsion;

[0101] In step (2.3), the mixed solution is heated to 122° C. for 20 seconds to sterilize;

[0102] Step (4) Cool the double-fermented drinking yoghurt to 2°C, fill it, and store it in a cold storage at 2°C.

Embodiment 6

[0104] Compared with embodiment 4, the difference only lies in:

[0105] Step (1.1) The raw milk sterilization temperature is 90°C;

[0106] Step (1.3) Cool down the mixed milk to 40°C and then add water;

[0107] Step (1.4) heating the mixed emulsion to 98°C for 240s, cooling to 44°C to obtain pretreated milk;

[0108] Step (1.5) inoculate the strain Premium 1.0 in the pretreated milk, ferment at 44°C at a constant temperature until the acidity is 105°T, and then break the emulsion;

[0109] In step (2.3), the mixed solution is heated to 128° C. for 15 seconds to sterilize;

[0110] Step (4): Cool the double-fermented drinking yoghurt to 6°C, fill it, and store it in a cold storage at 6°C.

[0111] The implementation principle of Examples 1-6 is: by adding white granulated sugar to milk, the fermented dry matter is increased in the milk, which is beneficial to the fermentation, makes the fermentation effect better, and the quality of the fermented milk obtained is better. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com