High-strength polyurethane heat preservation cushion block bi-component raw material for refrigeration house and preparation method thereof

A high-strength, polyurethane technology, which is used in the design of steel structure cold storage column foot insulation, heat preservation pads and its preparation, can solve the problems of cold storage steel structure column foot breaking cold, low thermal conductivity, high strength insulation pads, etc. To achieve the effects of rapid demoulding, reduced dosage, and increased rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

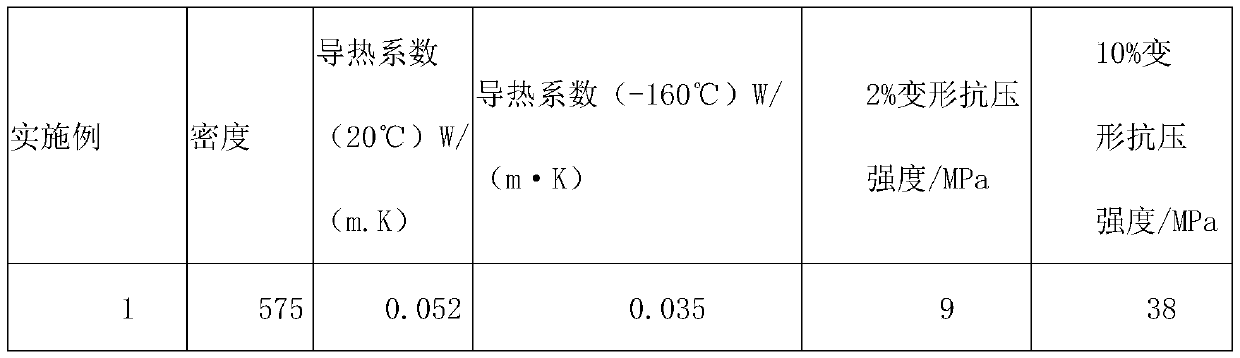

Examples

Embodiment 1

[0029] The two-component raw material of a high-strength polyurethane insulation pad for cold storage in this embodiment includes component A and component B.

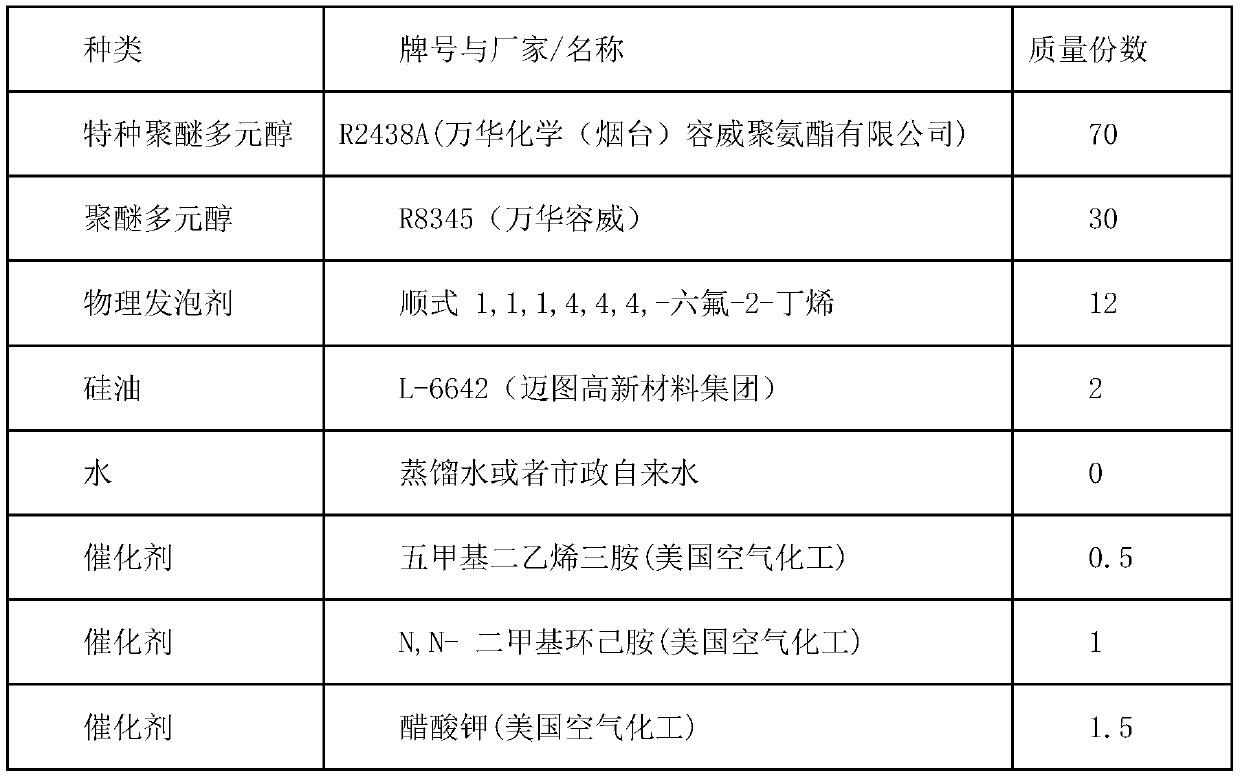

[0030] A component:

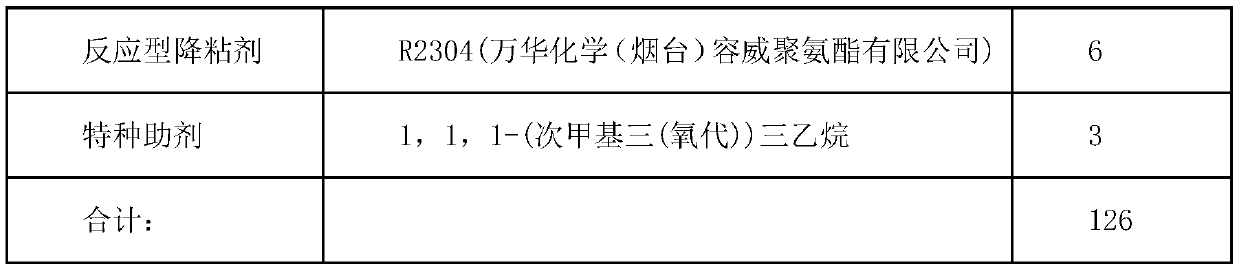

[0031]

[0032]

[0033] Isocyanate component: polymethylene polyphenyl isocyanate PM-400 (Wanhua Chemical Group Co., Ltd.);

[0034] The mass ratio of isocyanate component to polyol component is 140:100;

[0035] 1,1,1-(Methylenetri(oxo))triethane accounts for 2.4% of polyol A component; blowing agent cis 1,1,1,4,4,4,- The proportion of hexafluoro-2-butene is 9.5%;

[0036] The measured moisture of polyol A component is 0.02%;

[0037] Production steps:

[0038] (1) Heat the 300*300*50 steel mold to 40 degrees;

[0039] (2) Pre-mix component A, stir for more than 15 minutes, and let stand overnight;

[0040] (3) The isocyanate component and the polyol component are mixed under a pressure of 28MPa, so that the polyol component and the isocyanate component are fully mixed, and then pour...

Embodiment 2

[0046] The two-component raw material of a high-strength polyurethane insulation pad for cold storage in this embodiment includes component A and component B.

[0047] A component:

[0048]

[0049]

[0050] Isocyanate component: polymethylene polyphenyl isocyanate PM-400 (Wanhua Chemical Group Co., Ltd.);

[0051] The mass ratio of isocyanate component to polyol component is 150:100;

[0052] 1,1,1-(Methylenetri(oxo))triethane accounts for 1.6% of polyol A component; blowing agent cis 1,1,1,4,4,4,- The proportion of hexafluoro-2-butene is 8.1%;

[0053] The measured moisture of polyol A component is 0.05%;

[0054] Production steps:

[0055] (1) Heat the 300*300*50 steel mold to 40 degrees;

[0056] (2) Pre-mix component A, stir for more than 15 minutes, and let stand overnight;

[0057] (3) The isocyanate component and the polyol component are mixed under a pressure of 26MPa, so that the polyol component and the isocyanate component are fully mixed, and then poured...

Embodiment 3

[0063] The two-component raw material of a high-strength polyurethane insulation pad for cold storage in this embodiment includes component A and component B.

[0064] A component:

[0065] type Brand and manufacturer / name parts by mass Specialty Polyether Polyols TD405 (Guodu Chemical (Kunshan) Co., Ltd.) 30 Specialty Polyether Polyols R2438A (Wanhua Chemical (Yantai) Rongwei Polyurethane Co., Ltd.) 40 Polyether polyol 635 (Zibo Nuoli Chemical) 30 Physical blowing agent cis 1,1,1,4,4,4,-hexafluoro-2-butene 12 silicone oil L-6642 (Momentive Advanced Materials Group) 2 water Distilled water or municipal tap water 0 catalyst Pentamethyldiethylenetriamine (Air Chemicals, USA) 0.6 catalyst N,N-Dimethylbenzylamine (Air Chemicals, USA) 0.9 catalyst Potassium acetate (Air Chemicals, USA) 1.5 Reactive viscosity reducer R2304 (Wanhua Chemical (Yantai) Rongwei Polyurethane Co., Ltd.) 6 Speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com