A kind of natural rubber/white carbon black composite material and its preparation method and application

A technology of natural rubber and composite materials, applied in the field of rubber, which can solve the problems of long production cycle of composite materials, waste of manpower and material resources, poor aging resistance and anti-vulcanization reversion of rubber materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a method for preparing the natural rubber / silica composite material described in the above technical solution, comprising the following steps:

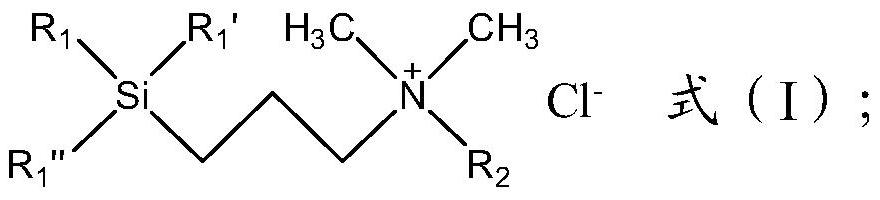

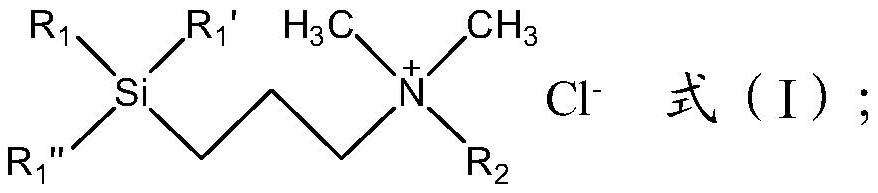

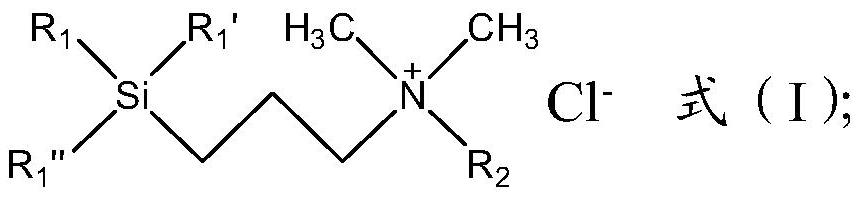

[0031] a) mixing natural rubber latex, white carbon black and a flocculant to obtain a floc gel; the flocculant used for the flocculation includes calcium chloride and organosilicon quaternary ammonium salt;

[0032] b) Dehydrating and drying the flocculated gel to obtain a natural rubber / silica composite material.

[0033] In the preparation method provided by the invention, firstly, natural latex, white carbon black and flocculant are mixed. Wherein, the flocculant includes calcium chloride and organosilicon quaternary ammonium salt, and the specific types of the organosilicon quaternary ammonium salt have been introduced above, and will not be repeated here. In the present invention, based on the dry weight of the natural rubber latex as 100 phr, the amount of the silica is preferably ≤10...

Embodiment 1

[0046] 1) Preparation of natural rubber / silica composite material

[0047] S1 prepares calcium chloride solution:

[0048] A calcium chloride aqueous solution with a concentration of 0.5wt% was prepared for subsequent use; the amount of calcium chloride used in the subsequent flocculation process was 2.7 phr based on the dry weight of the natural latex in the subsequent flocculation process as 100 phr.

[0049] Preparation of S2 natural rubber latex and silica premixed solution:

[0050] Get centrifugal concentrated natural latex, mix and dilute to natural latex solid content with white carbon black and be 18wt%, white carbon black fraction is 20phr (based on the dry weight of natural latex being 100phr), and add 0.2phr dimethyl octadecadecane Alkyl[3-(trimethoxysilyl)propyl]ammonium chloride, mechanical stirring (200rpm), ultrasonic (6000W) dispersion for 5 minutes, set aside.

[0051] S3 flocculation:

[0052] Under normal temperature and pressure, use a flow pump to cont...

Embodiment 2

[0061] 1) Preparation of natural rubber / silica composite material

[0062] S1 prepares calcium chloride solution:

[0063] A calcium chloride aqueous solution with a concentration of 0.7wt% was prepared for subsequent use; the amount of calcium chloride used in the subsequent flocculation process was 3.5 phr based on the dry weight of the natural rubber latex in the subsequent flocculation process as 100 phr.

[0064] Preparation of S2 natural rubber latex and silica premixed solution:

[0065] Get the fresh latex in the field, mix and dilute to latex solid content with white carbon black and be 22wt%, white carbon black fraction is 40phr (the dry weight of natural rubber latex is 100phr), and add the dimethyl octadecyl of 0.3phr [3-(trimethoxysilyl)propyl]ammonium chloride, mechanical stirring (200rpm), ultrasonic wave (1500W) disperse for 15 minutes, set aside.

[0066]S3 flocculation:

[0067] Under normal temperature and pressure, use a flow pump to continuously convect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com