Preparation and application of hierarchical pore-low valent iron Fenton sludge-based heterogeneous catalyst

A heterogeneous catalyst, low-valent iron technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of low reaction mass transfer efficiency and slow rate , secondary pollution and other problems, to achieve the effect of reducing disposal and resource utilization, high efficiency, and small secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation steps of Fenton sludge-based heterogeneous catalyst are as follows:

[0030] (1) Dry the Fenton sludge at 105°C, crush and grind it and pass through a 120-mesh sieve to make Fenton sludge raw material;

[0031] (2) Take the sieved Fenton sludge as raw material, add biochemical sludge as an auxiliary carbon source, mix the two evenly in proportion and place them in a fixed-bed reactor;

[0032] (3) Feed nitrogen into the fixed bed reactor at a gas flow rate of 100-120ml / min, control the heating rate of the reactor to be 3-10°C / min, the pyrolysis temperature to be 400-900°C, and the pyrolysis time to be 30 -90min, Fe3+ in Fenton sludge is reduced by reducing gas generated by pyrolysis to obtain low-priced iron Fenton sludge-based biochar;

[0033] (4) After the obtained low-priced iron Fenton sludge-based biochar is cooled, the biochar is transferred to the steam explosion tank, and after maintaining for 10 minutes under the conditions of the set temperat...

Embodiment 1

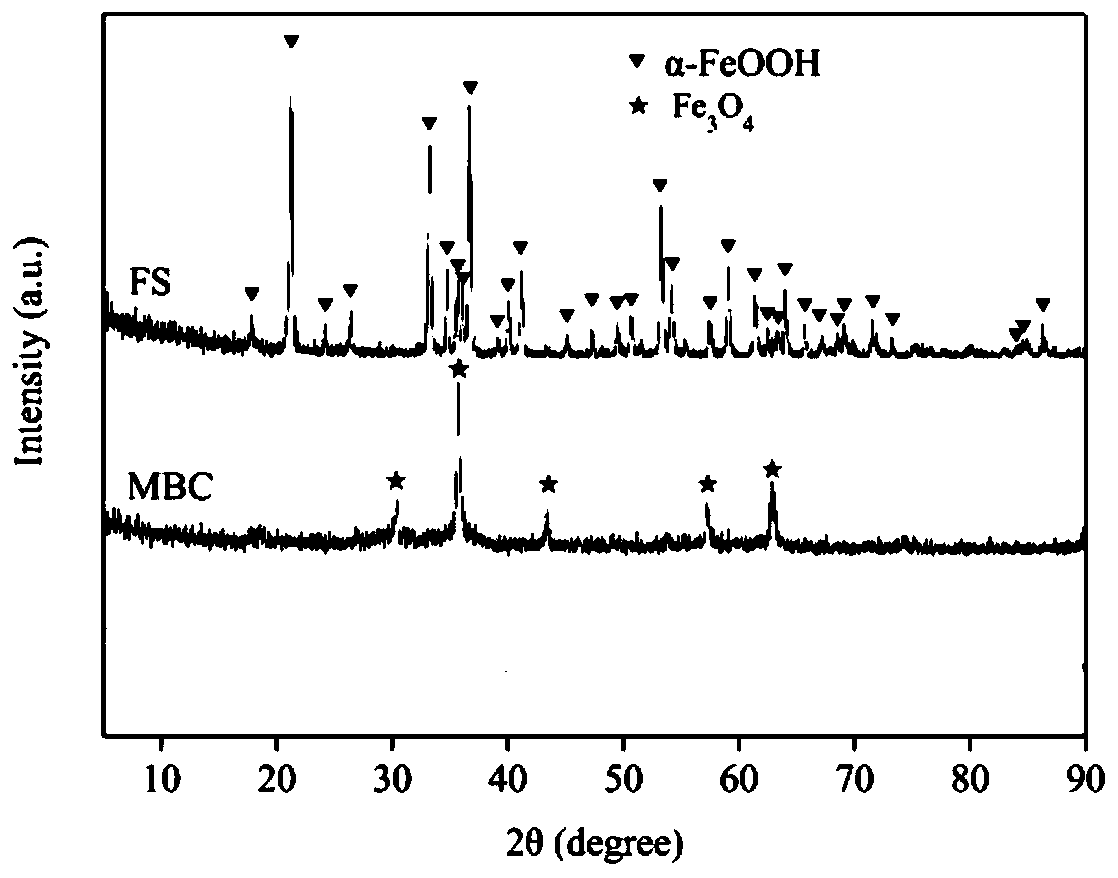

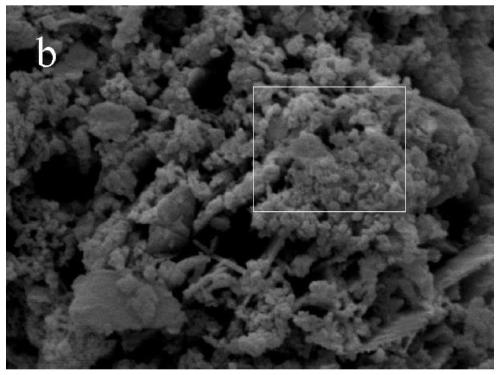

[0040] Example 1: Preparation and characterization process of low-temperature Fenton sludge-based heterogeneous catalyst and its application

[0041] (1) Take the printing and dyeing Fenton sludge and dry it at 105°C, crush it and pass it through a 120-mesh sieve;

[0042] (2) With sieved Fenton sludge as raw material, biochemical sludge as auxiliary carbon source, the two are mixed in a ratio of 3:1 and then filled in a boat-shaped crucible;

[0043] (3) Place the boat crucible in high temperature N 2 In the protective tube furnace, the heating rate was controlled to be 10°C / min, the pyrolysis temperature was 500°C, and the pyrolysis time was 60 minutes to obtain low-valent iron Fenton sludge-based biochar;

[0044] (4) After cooling the obtained biochar, under the conditions of 170°C temperature, 2.0MPa pressure and 10wt% water vapor content, the biochar was constructed by steam explosion method to obtain low-temperature Fenton sludge-based homogeneous catalyst.

[0045] ...

Embodiment 2

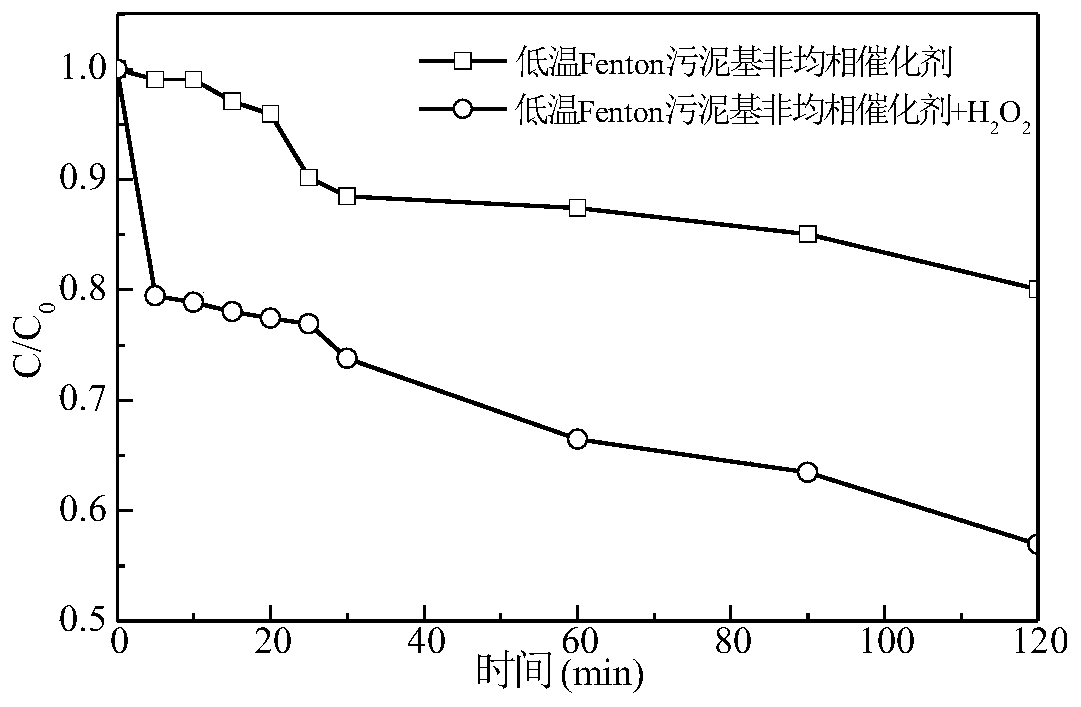

[0048] Example 2: High temperature Fenton sludge-based heterogeneous catalyst degradation methylene blue test

[0049] (1) Take the printing and dyeing Fenton sludge and dry it at 105°C, crush it and pass it through a 120-mesh sieve;

[0050] (2) With sieved Fenton sludge as raw material, biochemical sludge as auxiliary carbon source, the two are mixed in a ratio of 3:1 and then filled in a boat-shaped crucible;

[0051] (3) Place the boat crucible in high temperature N 2 In the protective tube furnace, the heating rate was controlled to be 5°C / min, the pyrolysis temperature was 800°C, and the pyrolysis time was 30 minutes to obtain low-valent iron Fenton sludge-based biochar;

[0052] (4) After cooling the obtained biochar, under the condition of temperature of 230°C, pressure of 2.7MPa and water vapor content of 15wt%, the biochar was constructed by steam explosion method to obtain high-temperature Fenton sludge-based homogeneous catalyst.

[0053] Prepare the methylene b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com