Anti-chemical decontamination device

A decontamination and decontamination agent technology, applied to chemical instruments and methods, cleaning methods using liquids, cleaning methods and appliances, etc., can solve the problems of limited continuous working time, harsh working environment, low working efficiency, etc., to achieve Improve the efficiency of chemical defense and decontamination, reduce the amount of input, and reduce the effect of decontamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

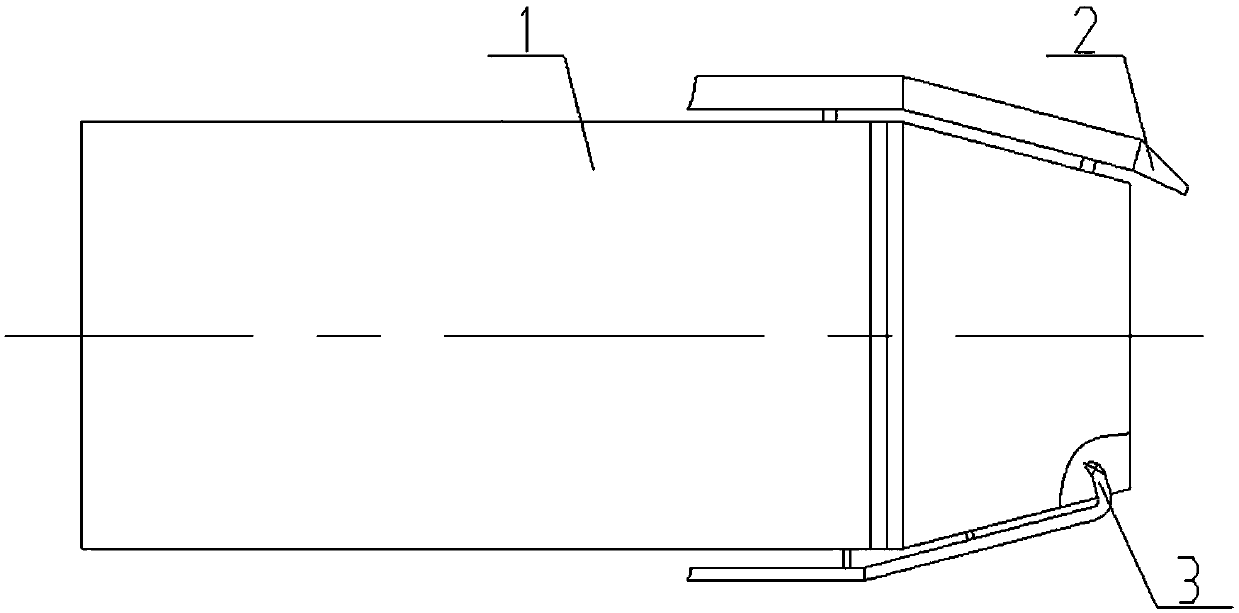

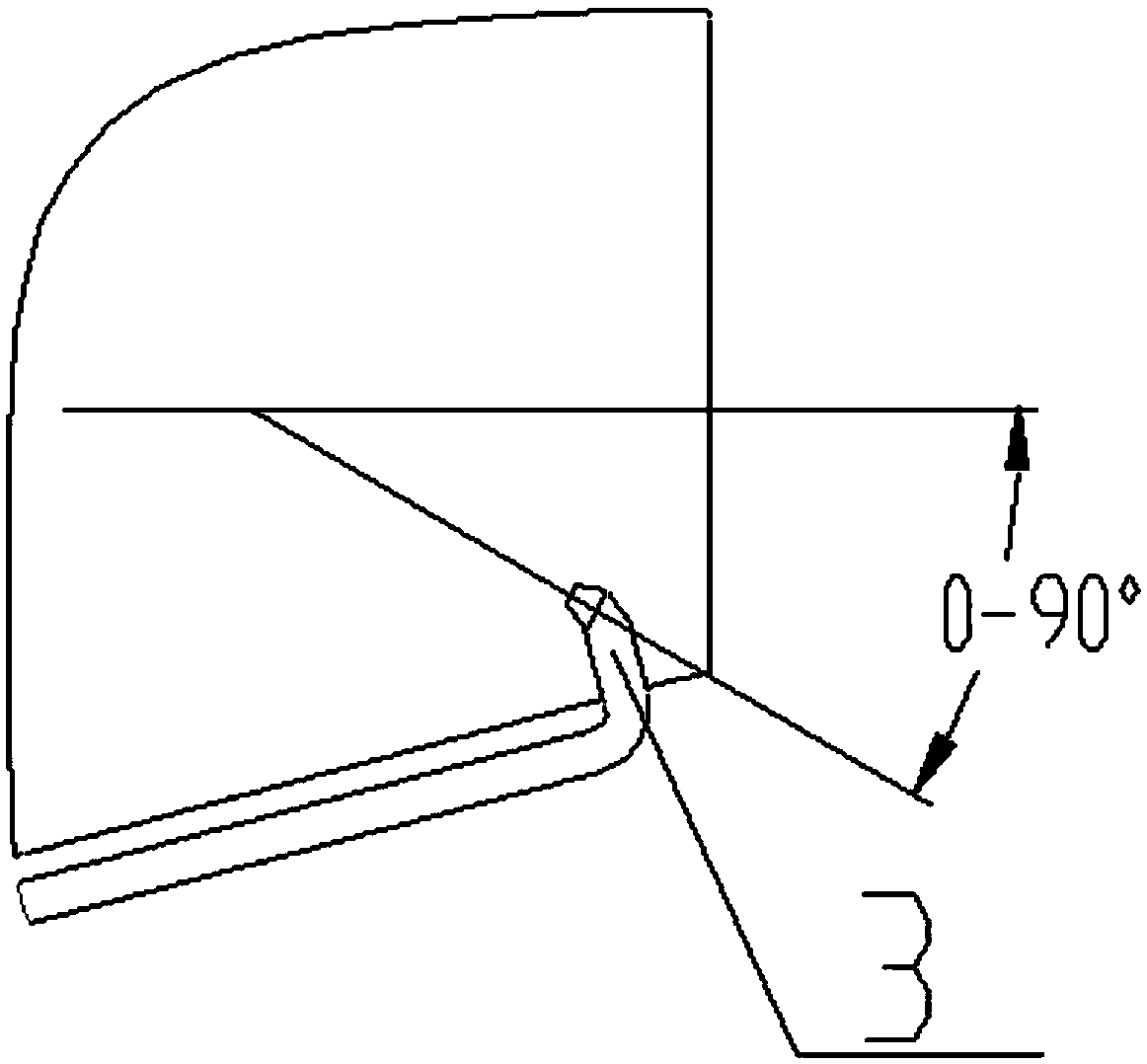

[0018] Please combine figure 1 and figure 2 Shown: a chemical-proof decontamination device provided in this embodiment, including a gas jet device 1, a liquid-based decontamination agent nozzle 2 and a solid-based powder decontamination agent nozzle 3, and the liquid-based decontamination agent nozzle 2 is installed on the gas jet Behind the spout of device 1, solid-base powder decontamination agent nozzle 3 is installed on the inside of the spout of gas jet device 1, and the injection direction of solid-base powder decontamination agent nozzle 3 is opposite to the jet flow axis direction of gas jet device, and is in line with the air flow. The included angle of the axis is 0-90 degrees.

[0019] The gas jet device 1 can spray the air after pressurizing it, and can use a motor, a hydraulic motor or an internal combustion engine as a fan driven by an internal combustion engine. The fan can be integrated or split, and can be an axial flow fan or a centrifugal fan. Or Roots bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com