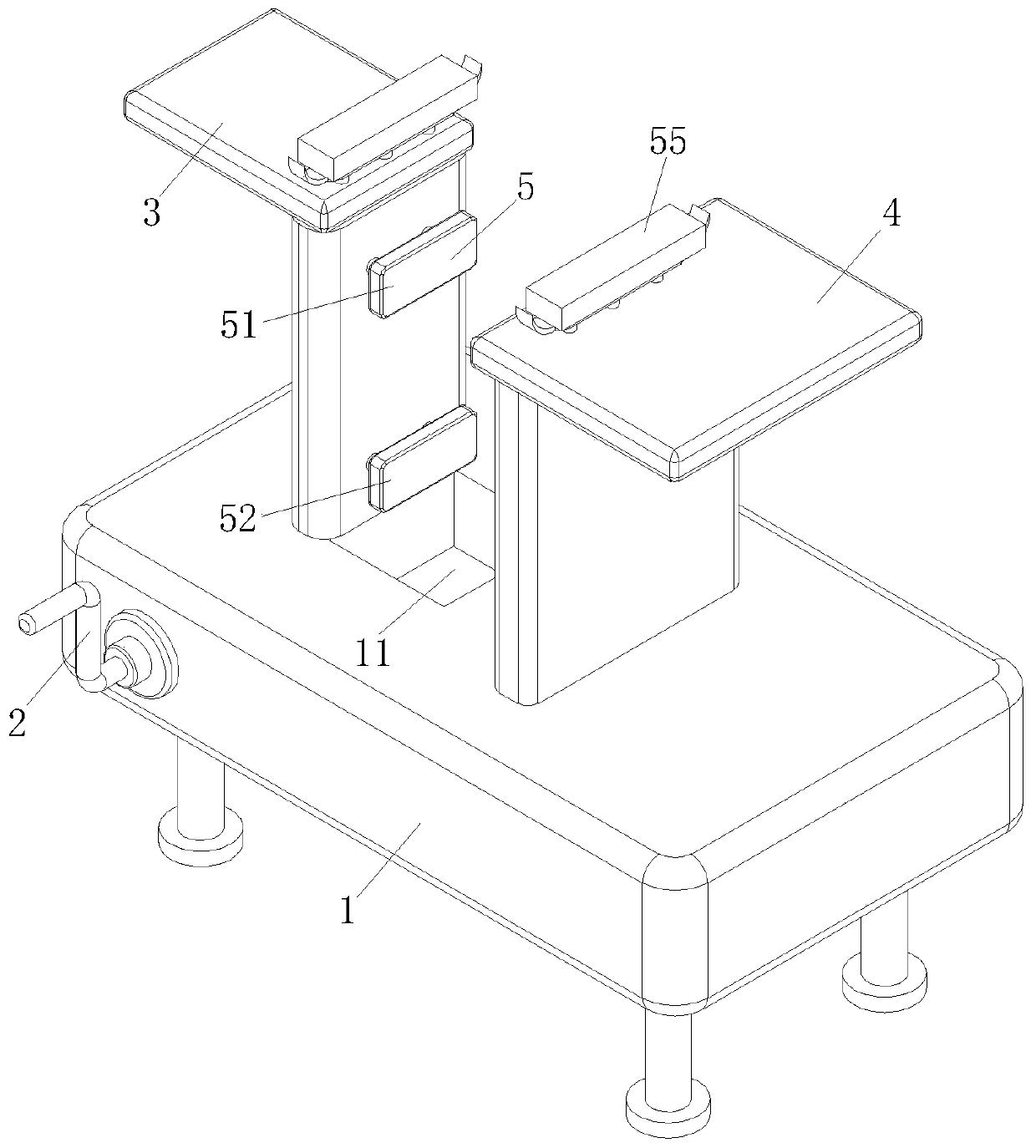

Brazing welding tool

A welding tooling and brazing technology, used in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of not being able to remove the oxide film of the billet in time, affecting the quality of brazing welding, etc., to strengthen clamping, reduce Welding difficulty, the effect of enhancing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

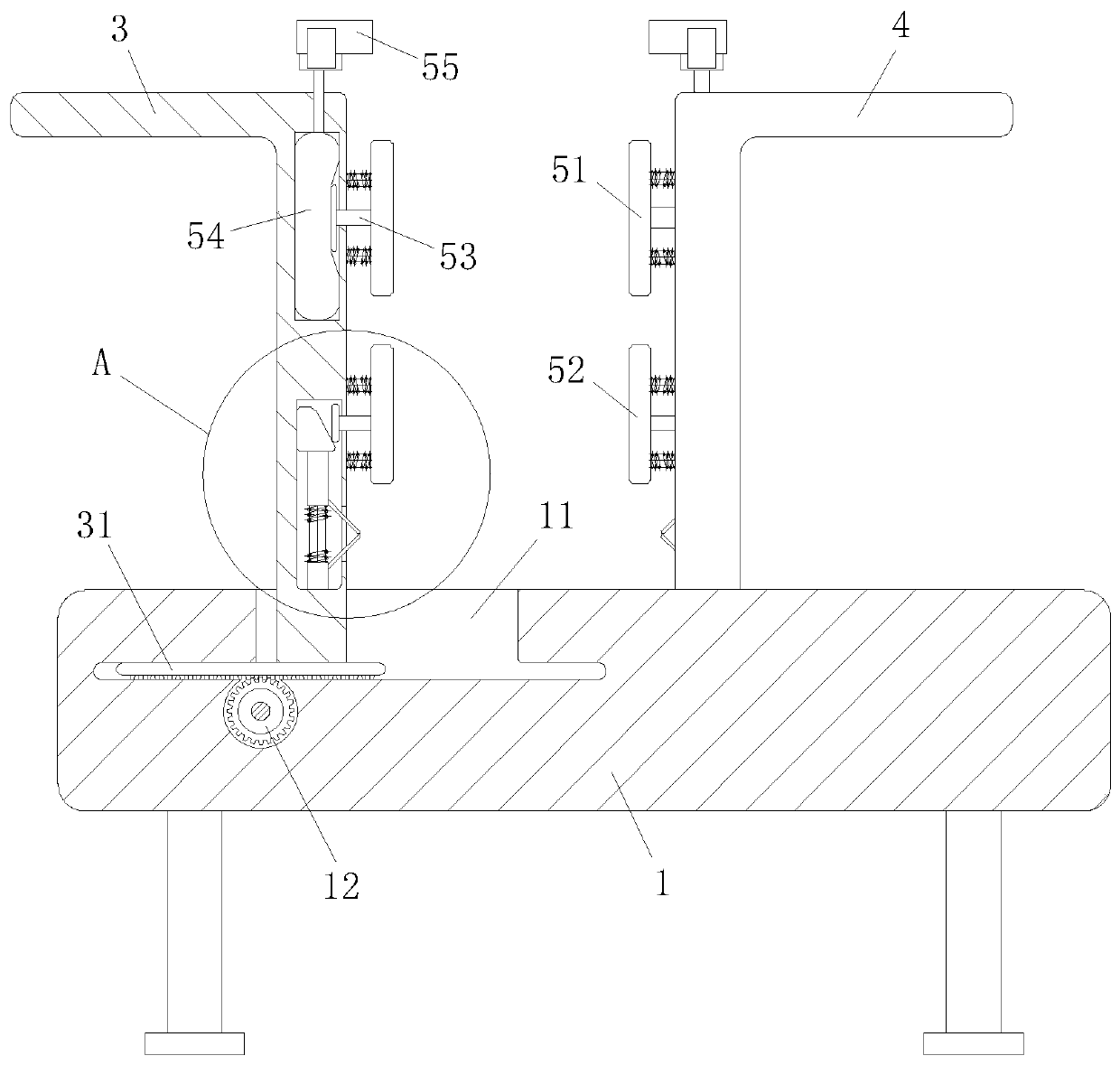

Method used

Image

Examples

Embodiment approach

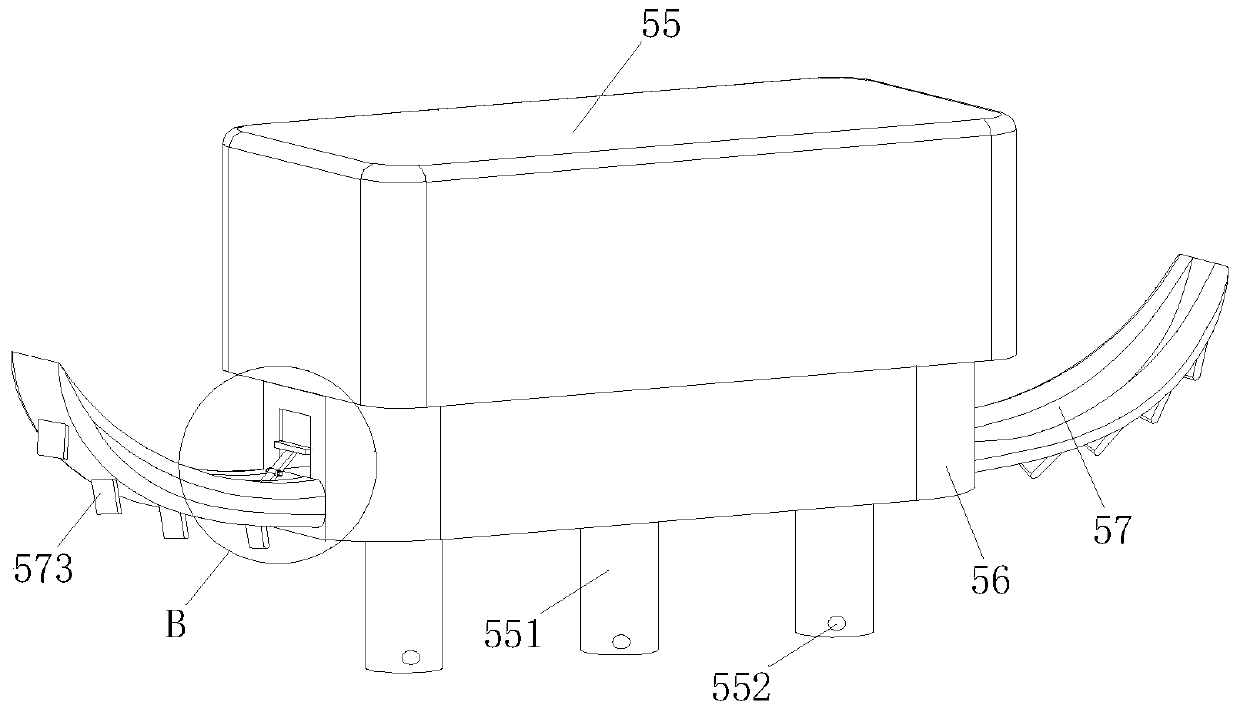

[0024] As an embodiment of the present invention, the inner wall of the scraper 57 is provided with a slide groove 571, and the slide groove 571 is hinged with a support rod 572 through a torsion spring near the side wall of the rubber bag 56; the rubber bag 56 There is a through hole 561 near the pole 572, and a baffle plate 562 is installed by a spring at the through hole 561, so that the bottom end of the baffle plate 562 is always in contact with the end of the pole 572; The cooperation of the support rod 572 and the baffle plate 562 realizes the collection of impurities on the surface of the billet; during operation, the rack 31 drives the extrusion plate 3 to slide in the direction close to the fixed plate 4 during the rotation of the gear 12 until it passes through the extrusion plate. 3 and the fixed plate 4 clamp the billet, at this time, the No. 1 pressing plate 51 is squeezed by the billet and moves, thereby driving the push rod 53 to squeeze the air bag 54, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap