Buckle type transmission grinding machine for stone floor and working method

A buckle-type, grinding machine technology, which is applied to machine tools, grinding racks, grinding machines, etc., which are suitable for grinding workpiece planes, and can solve the problems of many transmission parts of the grinding machine, fast wear of abrasive tools, and difficult operation of workers. , to achieve the effect of strong convenience, reduce dust, improve environment and personnel safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

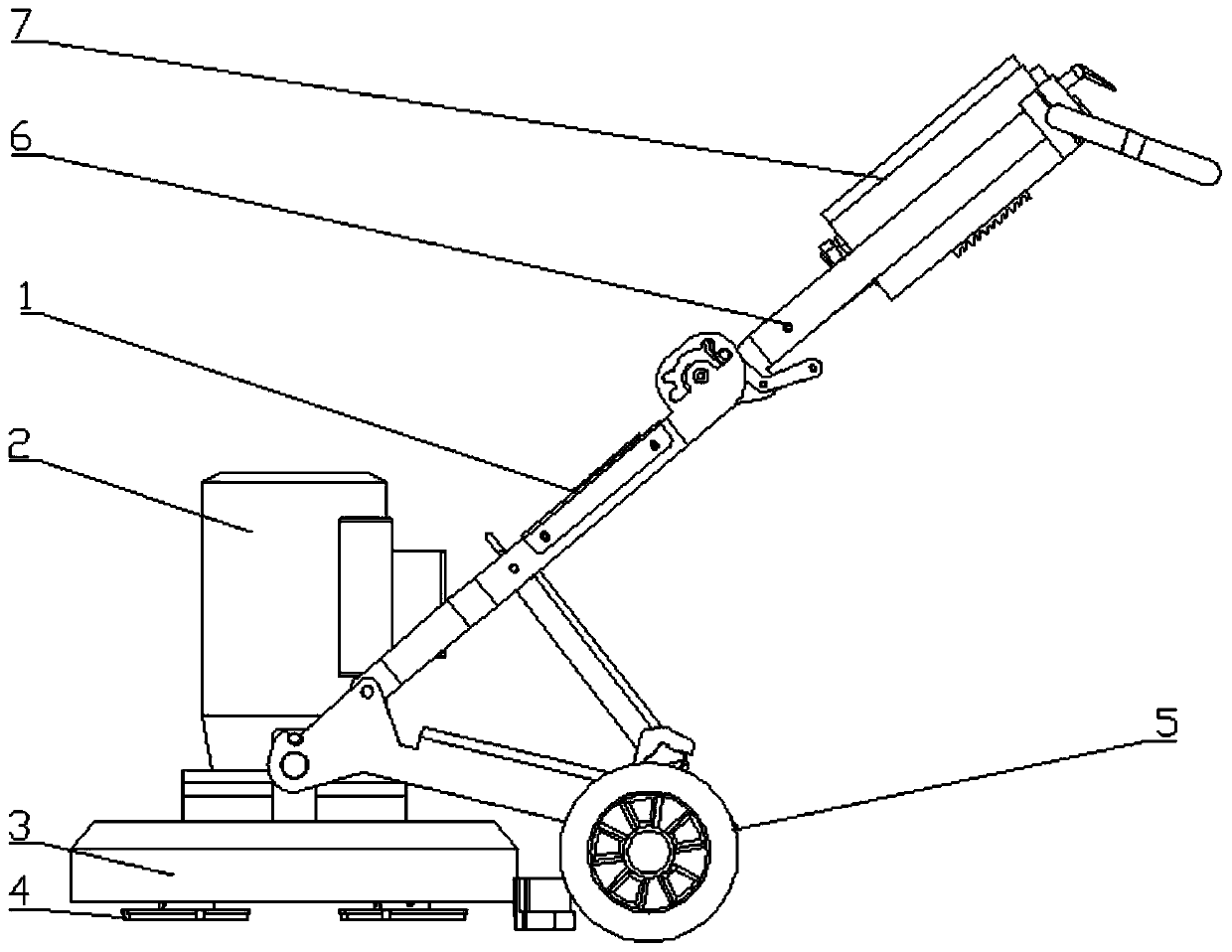

[0042] like Figure 1-6 A buckle-type transmission grinding machine for stone floors is shown, comprising: a frame 1, a motor 2, a transmission part 3, a grinding disc 4, a running wheel 5, a handle 6 and an electric box 7, and the frame 1 is in the shape of 4 In the shape of a font, one end of the frame 1 is provided with a transmission part 3, the top of the transmission part 3 is provided with a motor 2, and the bottom of the transmission part 3 is provided with a grinding disc 4; the bottom of the frame 1 is provided with a running wheel 5, and the A handle 6 is arranged on the top of the frame 1 , and an electric box 7 is fixedly arranged on the handle 6 , and the electric box 7 is connected to the motor 2 .

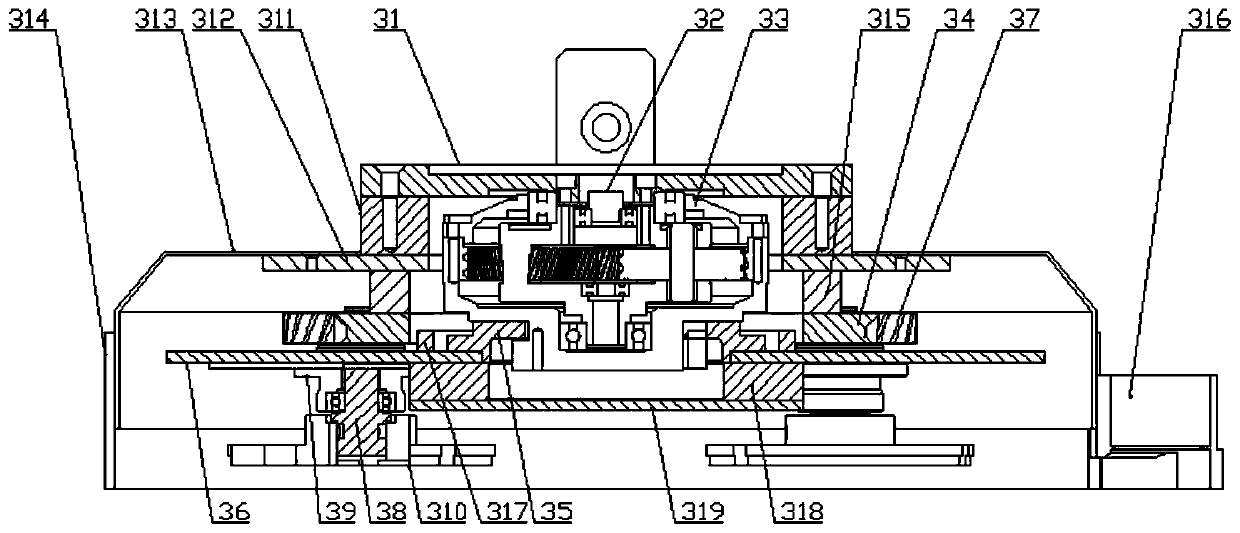

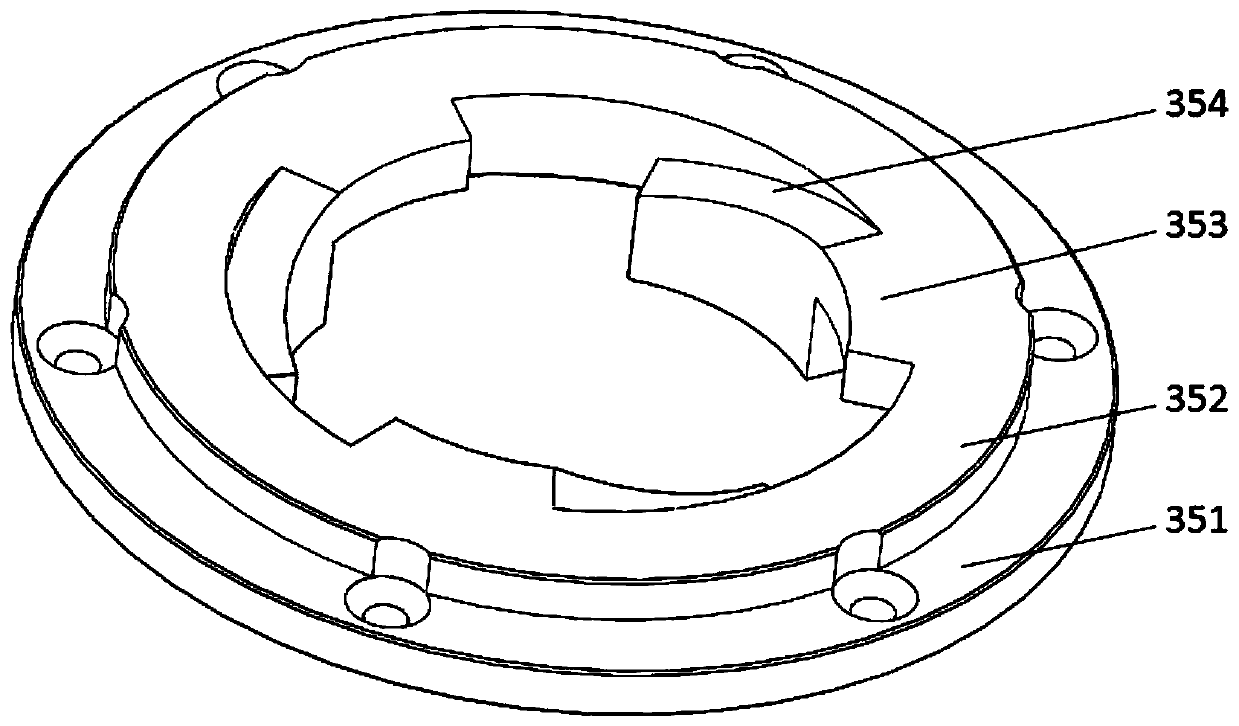

[0043]The transmission part 3 described in this embodiment includes a motor flange 31, a T-shaped pin shaft 32, a planetary wheel 33, a revolving gear 34, a buckle 35, a bottom plate 36, a millstone pinion 37, a gear shaft 38, and a fixed flange Disc 39 and grindin...

Embodiment 2

[0055] like Figure 1-5 A buckle-type transmission grinding machine for stone floors is shown, comprising: a frame 1, a motor 2, a transmission part 3, a grinding disc 4, a running wheel 5, a handle 6 and an electric box 7, and the frame 1 is in the shape of 4 In the shape of a font, one end of the frame 1 is provided with a transmission part 3, the top of the transmission part 3 is provided with a motor 2, and the bottom of the transmission part 3 is provided with a grinding disc 4; the bottom of the frame 1 is provided with a running wheel 5, and the A handle 6 is arranged on the top of the frame 1 , and an electric box 7 is fixedly arranged on the handle 6 , and the electric box 7 is connected to the motor 2 .

[0056] The transmission part 3 described in this embodiment includes a motor flange 31, a T-shaped pin shaft 32, a planetary wheel 33, a revolving gear 34, a buckle 35, a bottom plate 36, a millstone pinion 37, a gear shaft 38, and a fixed flange Disc 39 and grindi...

Embodiment 3

[0063] like figure 1 and 6 A buckle-type transmission grinding machine for stone floors is shown, comprising: a frame 1, a motor 2, a transmission part 3, a grinding disc 4, a running wheel 5, a handle 6 and an electric box 7, and the frame 1 is in the shape of 4 In the shape of a font, one end of the frame 1 is provided with a transmission part 3, the top of the transmission part 3 is provided with a motor 2, and the bottom of the transmission part 3 is provided with a grinding disc 4; the bottom of the frame 1 is provided with a running wheel 5, and the A handle 6 is arranged on the top of the frame 1 , and an electric box 7 is fixedly arranged on the handle 6 , and the electric box 7 is connected to the motor 2 .

[0064] The electric box 7 described in this embodiment includes a box body 71, a frequency converter 72, a power indicator light 73, a start switch 74, a speed control switch 75, an emergency stop switch 76 and a frequency converter panel 77, and the box body 71...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com