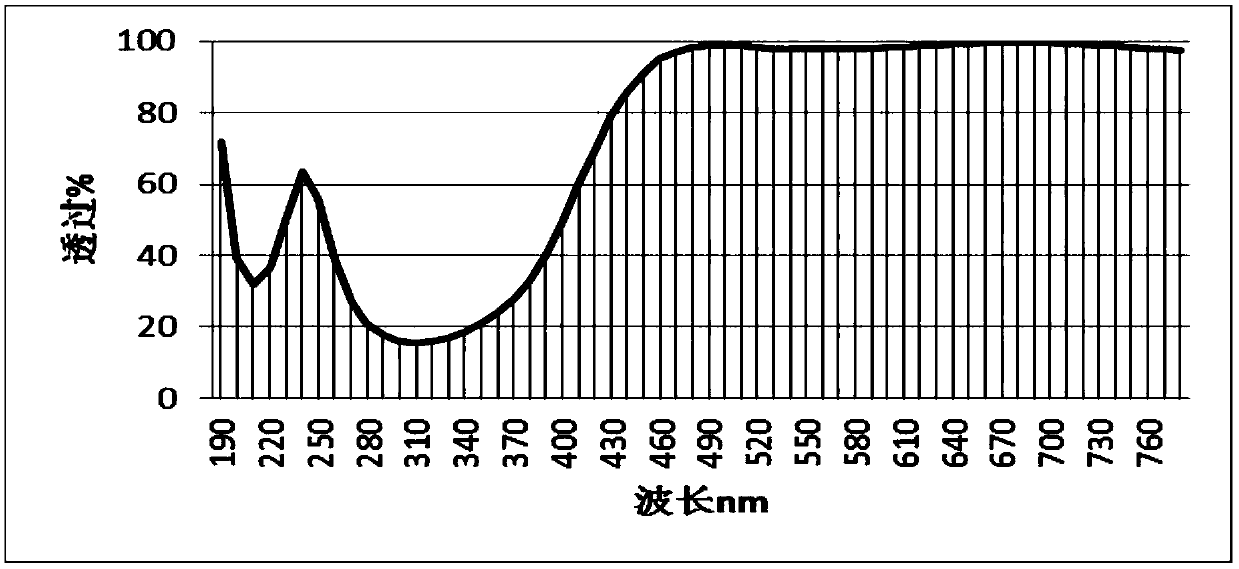

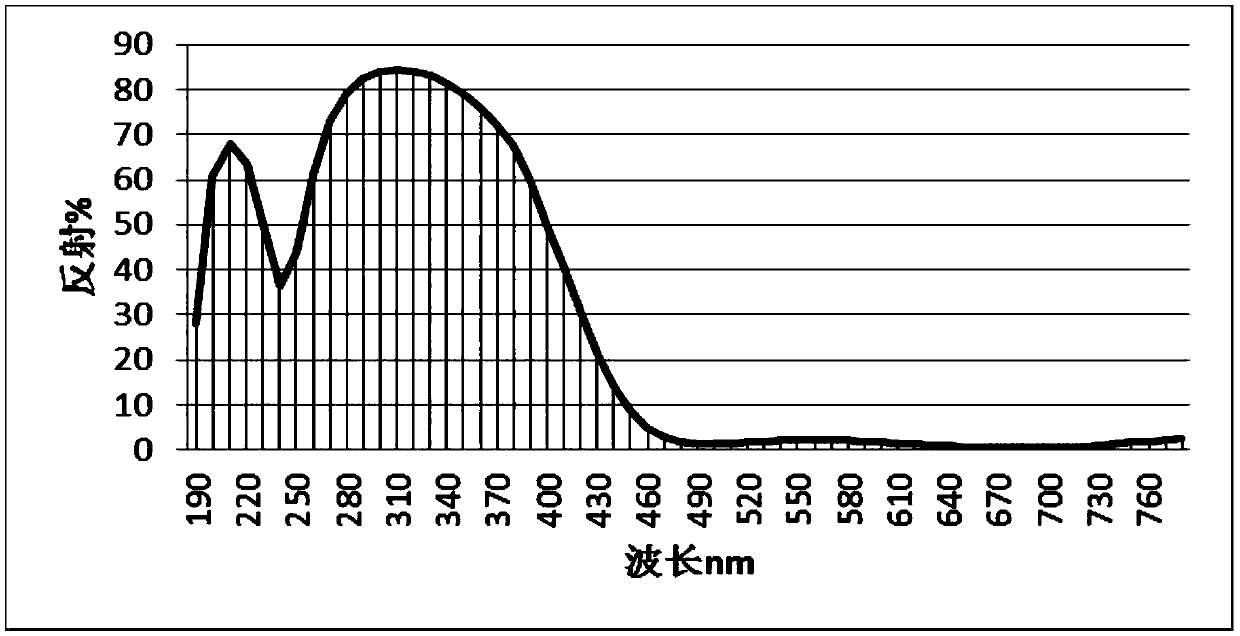

AR glass with ultraviolet-proof function, and production process thereof

A technology of UV protection and production process, applied in the field of AR glass, it can solve the problems of low transmittance, short service life, and inability to precisely control the film thickness, and achieve the effect of low material cost and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment, the temperature inside the box of the magnetron sputtering coating equipment is heated to 150°C-250°C, the vacuum degree is evacuated to a background vacuum of 5.0E-3pa, and then filled with 100sccm Ar gas to coat the first niobium oxide layer 2. The first silicon dioxide layer 3, the second niobium oxide layer 4, the second silicon dioxide layer 5, the third niobium oxide layer 7, the third silicon dioxide layer 8, the fourth niobium oxide layer 9 and the fourth two The cavity of silicon oxide layer 10 is filled with O 2 gas.

[0034] Further, the oxygen content of the SiAl target of the magnetron sputtering coating equipment is set to 60SCCM-75SCCM, the oxygen content of the Nb metal target is set to 80SCCM-90SCCM, and the graphite target position uses multiple groups of molecular pumps as gas wells, and the graphite target is filled with N 2 Gas is used as the reaction gas, the Ar gas flow is set to 80sccm ~ 100sccm, N 2 The gas flow rate is set...

Embodiment 2

[0037] When coating the front side of the glass substrate 1, the temperature inside the box of the magnetron sputtering coating equipment is first heated to 150-250°C, the vacuum degree is evacuated to below 3.6E-3pa, and then filled with Ar 2 Gas and O 2 Gas, first turn on the power of the Nb target, start to plate the first niobium oxide layer 2, then close the Nb target, open the Sial target, plate the first silicon dioxide layer 3, then close the Sial target, and open the Nb target again Power supply, plating the second niobium oxide layer 4, then turn off the power supply of the Nb target, turn on the Sial target, plate the second silicon dioxide layer 5, then turn off the Nb target and the SiAL target, turn off the gas source and discharge oxygen, and then turn off the Working gas Ar 2 The gas is adjusted to 80SCCM, filled with N 2 Gas 10SCCM~25SCCM, the first carbon nitride layer 6 is plated.

[0038] Further, the front side of the glass substrate 1 is coated with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com