Preparation method of p-hydroxybenzhydrazide compound

A technology for hydroxyphenylhydrazine and compounds, which is applied in the field of preparing p-hydroxyphenylhydrazine compounds, can solve problems such as poor selectivity, and achieve the effects of short reaction time, high product yield and good regioselectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

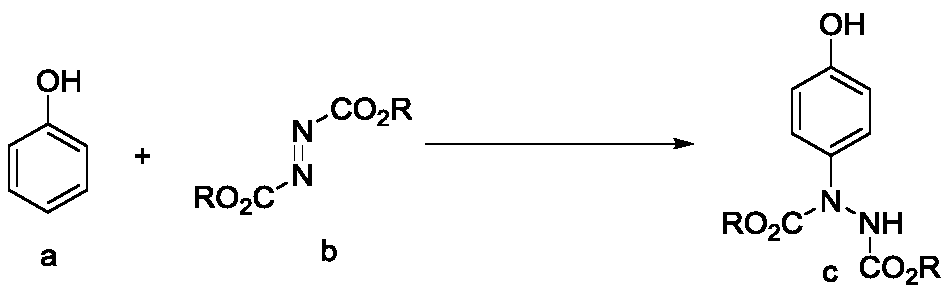

Image

Examples

Embodiment 1

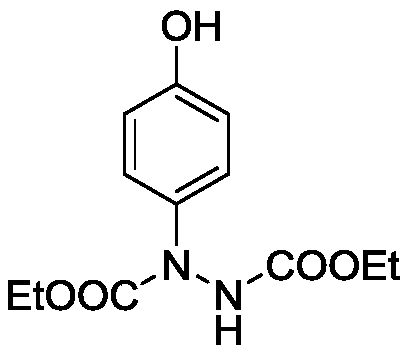

[0022] Preparation of Diethyl 1-(4-Hydroxyphenyl)hydrazine-1,2-dicarboxylate

[0023]

[0024] Add catalyst 3mol% Ag sequentially 2 O, 0.2mmol phenol, 0.4mmol diethyl azodicarboxylate, 2mL water and a No. 5 magnet. The reactor was placed in an ice bath to react for 0.5 hours. The reaction solution was poured into a separatory funnel, 15 mL of water was added, extracted 3 times with 10 mL of ethyl acetate, the obtained organic phases were combined, spin-dried by a rotary evaporator, and the crude product was separated and purified by column chromatography to obtain 1-(4-hydroxyl 48.8 mg of diethyl phenyl)hydrazine-1,2-dicarboxylate was a white solid with a yield of 91%.

[0025] Its structure was confirmed by H NMR and C NMR 1 H NMR (400MHz, CDCl 3 ):δ7.24(s,1H),6.99(s,1H),6.78–6.73(m,2H),5.43(s,1H),4.26–4.19(m,4H),1.30–1.25(m,6H ); 13 C NMR (100MHz, CDCl 3 ): δ156.7, 155.8, 155.3, 134.3, 127.0, 115.8, 63.3, 62.6, 14.5.

Embodiment 2

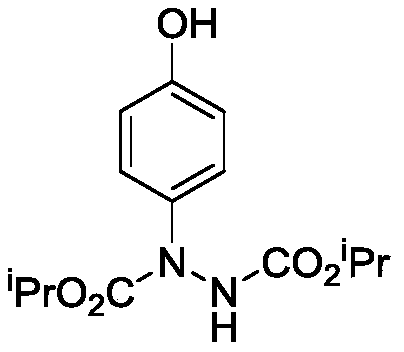

[0027] Preparation of Diisopropyl 1-(4-Hydroxyphenyl)hydrazine-1,2-dicarboxylate

[0028]

[0029] Add catalyst 3mol% Ag sequentially 2 O, 0.2mmol phenol, 0.4mmol diisopropyl azodicarboxylate, 2mL water and a No. 5 magnet. The reactor was placed in an ice bath to react for 0.5 hours. The reaction solution was poured into a separatory funnel, 15 mL of water was added, extracted 3 times with 10 mL of ethyl acetate, the obtained organic phases were combined, spin-dried by a rotary evaporator, and the crude product was separated and purified by column chromatography to obtain 1-(4-hydroxyl 47.4 mg of diisopropyl phenyl)hydrazine-1,2-dicarboxylate was a white solid with a yield of 80%.

[0030] Its structure was confirmed by H NMR and C NMR 1 H NMR (400MHz, CDCl 3 ):δ7.22–7.11(m,3H),6.69(d,J=8.32Hz,2H),5.02–4.92(m,2H),1.25(d,J=6.28Hz,12H),; 13 C NMR (100MHz, CDCl 3 ): δ156.4, 155.4, 155.2, 134.2, 126.7, 115.7, 71.1, 70.4, 22.1, 22.0.

Embodiment 3

[0032] Preparation of di-tert-butyl 1-(4-hydroxyphenyl)hydrazine-1,2-dicarboxylate

[0033]

[0034] Add catalyst 3mol% Ag sequentially 2 O, 0.2mmol phenol, 0.4mmol di-tert-butyl azodicarboxylate, 2mL water and a No. 5 magnet. The reactor was placed in an ice bath to react for 0.5 hours. The reaction solution was poured into a separatory funnel, 15 mL of water was added, extracted 3 times with 10 mL of ethyl acetate, the obtained organic phases were combined, spin-dried by a rotary evaporator, and the crude product was separated and purified by column chromatography to obtain 1-(4-hydroxyl 55.1 mg of di-tert-butyl phenyl)hydrazine-1,2-dicarboxylate (C-ac) was a white solid with a yield of 85%.

[0035] Its structure was confirmed by H NMR and C NMR 1 H NMR (400MHz, CDCl 3 ):δ7.18–7.12(m,2H),6.87(s,1H),6.65(d,J=8.24Hz,2H),6.54(s,1H),1.48(s,18H); 13 C NMR (100MHz, CDCl 3 ): δ155.6, 154.7, 134.7, 126.5, 115.6, 82.4, 81.8, 28.4, 28.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com