Environment-friendly high-weather-resistance high-hardness sand-in-sand stone-like paint and preparation process thereof

A high-hardness, imitation stone paint technology, applied in the field of sand bag sand imitation, can solve the problems of environmental protection, general physical properties of stone imitation paint, etc., and achieve the effect of improving physical properties and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

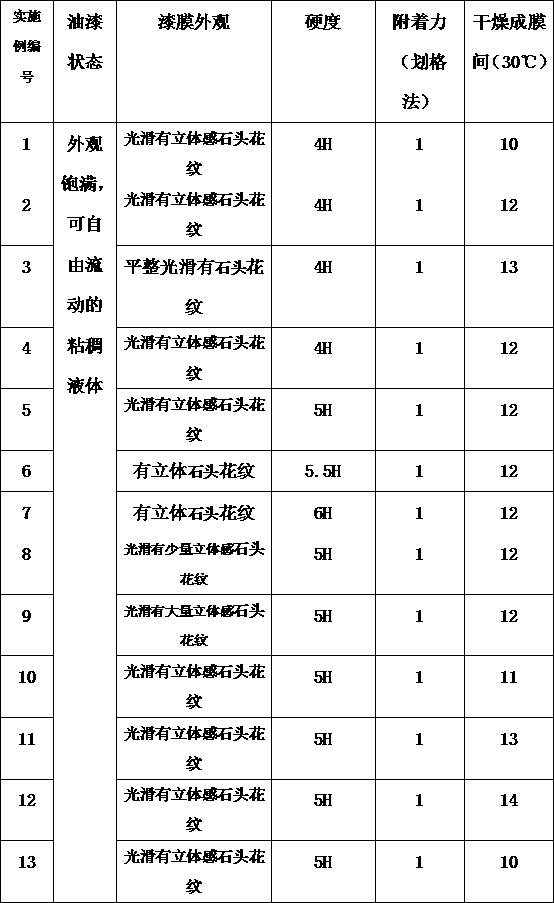

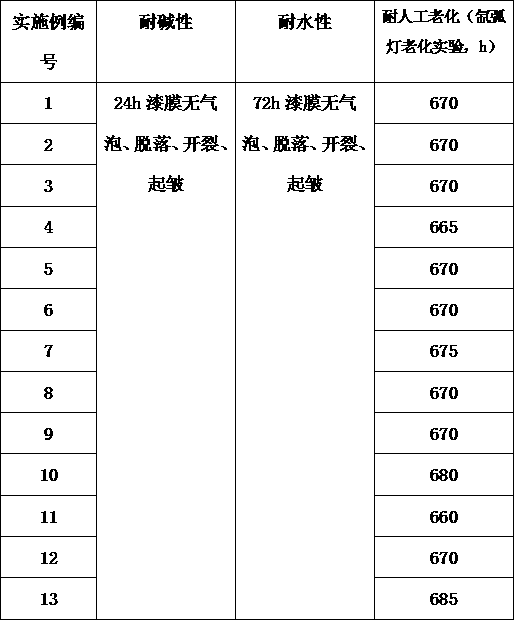

Examples

Embodiment 1

[0038] A preparation process of an environmentally friendly, weather-resistant and high-hardness sand-in-sand imitation stone paint, said method comprising the following steps:

[0039] (1) Grind the hexacyclite into powder particles and soak in deionized water for 30 minutes to completely infiltrate, and the bamboo charcoal fibers are broken so that the length does not exceed 3CM;

[0040] (2) The modified acrylic resin emulsion, infiltrated hexacyclite, wetting agent, dispersant, PH regulator, leveling agent, defoamer, antifreeze, preservative, modified compound additive and the remaining deionized water Slowly add to the stirring tank one by one, and stir for 30-40min at a speed of 800-1000r / min;

[0041] (3) Add film-forming aids and thickeners in sequence, and stir for 30-40 minutes at a speed of 800-1000 r / min;

[0042] (4) Add bamboo charcoal fiber and stir for 20 to 30 minutes at a speed of 1000 to 1200 r / min to obtain the required sand-in-sand imitation stone paint w...

Embodiment 2

[0045] A preparation process of an environmentally friendly, weather-resistant and high-hardness sand-in-sand imitation stone paint, said method comprising the following steps:

[0046] (1) Grind the hexacyclite into powder particles and soak in deionized water for 30 minutes to completely infiltrate, and the bamboo charcoal fibers are broken so that the length does not exceed 3CM;

[0047] (2) The modified acrylic resin emulsion, infiltrated hexacyclite, wetting agent, dispersant, PH regulator, leveling agent, defoamer, antifreeze, preservative, modified compound additive and the remaining deionized water Slowly add to the stirring tank one by one, and stir for 30-40min at a speed of 800-1000r / min;

[0048] (3) Add film-forming aids and thickeners in sequence, and stir for 30-40 minutes at a speed of 800-1000 r / min;

[0049] (4) Add bamboo charcoal fiber and stir for 20 to 30 minutes at a speed of 1000 to 1200 r / min to obtain the required sand-in-sand imitation stone paint w...

Embodiment 3

[0052] A preparation process of an environmentally friendly, weather-resistant and high-hardness sand-in-sand imitation stone paint, said method comprising the following steps:

[0053] (1) Grind the hexacyclite into powder particles and soak in deionized water for 30 minutes to completely infiltrate, and the bamboo charcoal fibers are broken so that the length does not exceed 3CM;

[0054] (2) The modified acrylic resin emulsion, infiltrated hexacyclite, wetting agent, dispersant, PH regulator, leveling agent, defoamer, antifreeze, preservative, modified compound additive and the remaining deionized water Slowly add to the stirring tank one by one, and stir for 30-40min at a speed of 800-1000r / min;

[0055] (3) Add film-forming aids and thickeners in sequence, and stir for 30-40 minutes at a speed of 800-1000 r / min;

[0056] (4) Add bamboo charcoal fiber and stir for 20 to 30 minutes at a speed of 1000 to 1200 r / min to obtain the required sand-in-sand imitation stone paint w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com