Method for testing crosslinking degree of crosslinked polyethylene

A technology of cross-linked polyethylene and testing methods, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, strength characteristics, etc., can solve the problems of toxic test time, long (8h, etc.), and achieve difficult decomposition, The effect of chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Select a pipe with a cross-linking degree range of 0-10%, an outer diameter of 1.5±0.05cm, and an inner diameter of 1.0±0.05cm, and heat the middle of the pipe with a heating zone width of 2cm and a heating temperature of 200℃ , Set blocks at both ends of the heating area to ensure that the outside of the heating area is not heated.

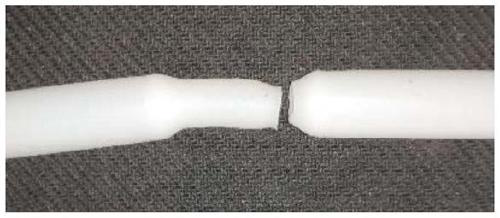

[0032] (2) Use a universal tensile testing machine to break the heated pipe in step (1) at a rate of 500mm / min. After the pipe is completely cooled, take a picture of the fracture surface, such as figure 1 The length of the heating zone after fracture, the radial size after the heating zone is broken, and the morphological characteristics of the fracture are recorded.

Embodiment 2

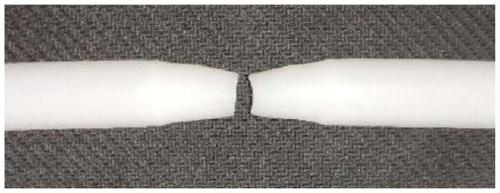

[0034] Select a pipe with a cross-linking degree range of 10-20%, an outer diameter of 1.5±0.05 cm, and an inner diameter of 1.0±0.05 cm. The heating area, heating temperature and breaking method of the pipe are the same as those in Example 1. The radial direction generated when the pipe is heated The shape of expansion and axial contraction is like image 3 Shown. After the pipe is completely cooled, take a picture of its fracture surface, such as figure 2 As shown, and record the length of the heated area after fracture, the radial size of the heated area after fracture, and the morphological characteristics of the fracture.

Embodiment 3

[0036] Select a pipe with a cross-linking degree of 20-30%, an outer diameter of 1.5±0.05cm, and an inner diameter of 1.0±0.05cm. The heating area, heating temperature and breaking method of the pipe are the same as those in Example 1. After the pipe is completely cooled, Take pictures of its fracture topography, such as Figure 4 As shown, the length of the heated area after fracture, the radial size of the heated area after fracture, and the morphological characteristics of the fracture are recorded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com