Sulfur-modified chloroprene rubber composition, vulcanized product, molded article using said vulcanized product and method for producing sulfur-modified chloroprene rubber composition

A technology of chloroprene rubber and chloroprene, applied to sulfur-modified chloroprene rubber compositions and vulcanized products, molded articles using the vulcanized compounds, and sulfur-modified chloroprene rubber compositions In the manufacturing field, it achieves the effect of reducing heat generation, compression set and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] Hereinafter, the present technology will be described in more detail based on examples. In addition, the embodiment described below shows an example of the representative embodiment of this technology, and does not limitatively interpret the protection scope of this technology by this.

[0069] [Production of sulfur-modified chloroprene rubber]

[0070]

[0071] (1) Add 100 parts by mass of chloroprene monomer, 0.55 parts by mass of sulfur, 120 parts by mass of pure water, and 4.00 parts by mass of disproportionated potassium abietate (manufactured by Harima Chemicals Co., Ltd.) to a polymerization tank with an inner volume of 30 liters , 0.60 parts by mass of sodium hydroxide, and 0.6 parts by mass of sodium salt of β-naphthalenesulfonic acid formaldehyde condensate (trade name Demol N: manufactured by Kao Corporation). The pH of the aqueous emulsifier before the start of polymerization was 12.8. 0.1 parts by mass of potassium persulfate was added as a polymerizati...

Embodiment 2~13 and comparative example 1~4

[0077] According to the formulations shown in Tables 1 and 2 below, sulfur-modified chloroprene rubber (raw rubber) was obtained by the same method as in Example 1.

[0078] In addition, each material used in this Example is as follows.

[0079] N-tert-butylbenzothiazole-2-sulfenamide: (trade name "Sanceler NS-G" manufactured by Sanshin Chemical Industry Co., Ltd.)

[0080] Diethyl xanthate disulfide: (manufactured by Sigma-Aldrich)

[0081] Tetraethylthiuram disulfide: (trade name "Nocceler TET" manufactured by Ouchi Shinko Chemical Industry Co., Ltd.)

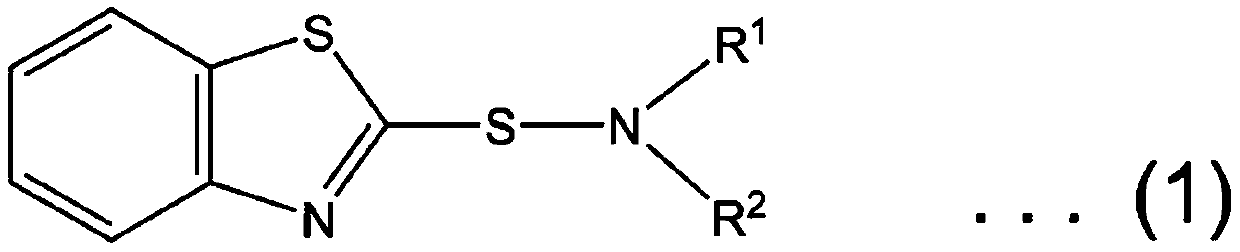

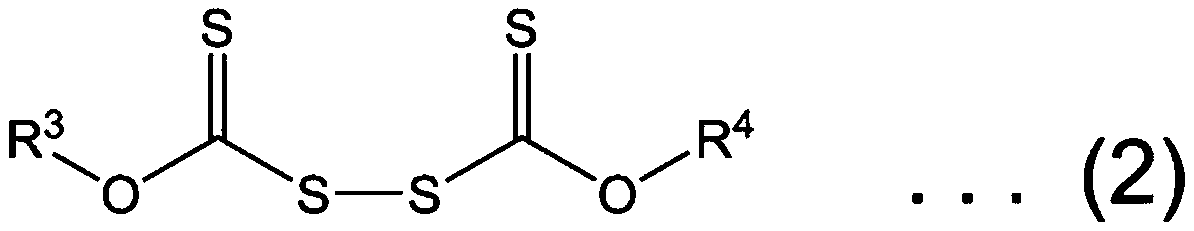

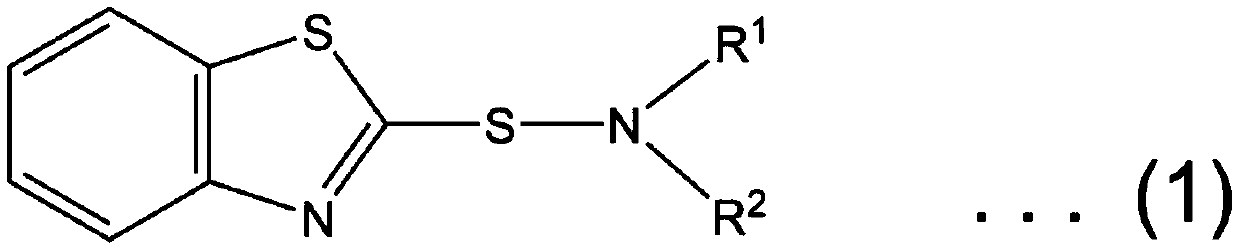

[0082] [Analysis of content of plasticizer (compound represented by chemical formula (1) and chemical formula (2))]

[0083] The content of the compounds represented by the chemical formula (1) and the chemical formula (2) in the sulfur-modified chloroprene rubber was quantified according to the following steps.

[0084] After dissolving 1.5 g of the obtained sulfur-modified polychloroprene rubber in 30 ml of benzene, 60 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com