Preparation method of an edible enzyme food with alpha amylase (alpha-amylase)

A technology of Bacillus subtilis and food, which is applied in the field of food preparation using edible enzymes of Bacillus subtilis, which can solve the problems of bacteremia, difficulty in death, high cost and facilities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

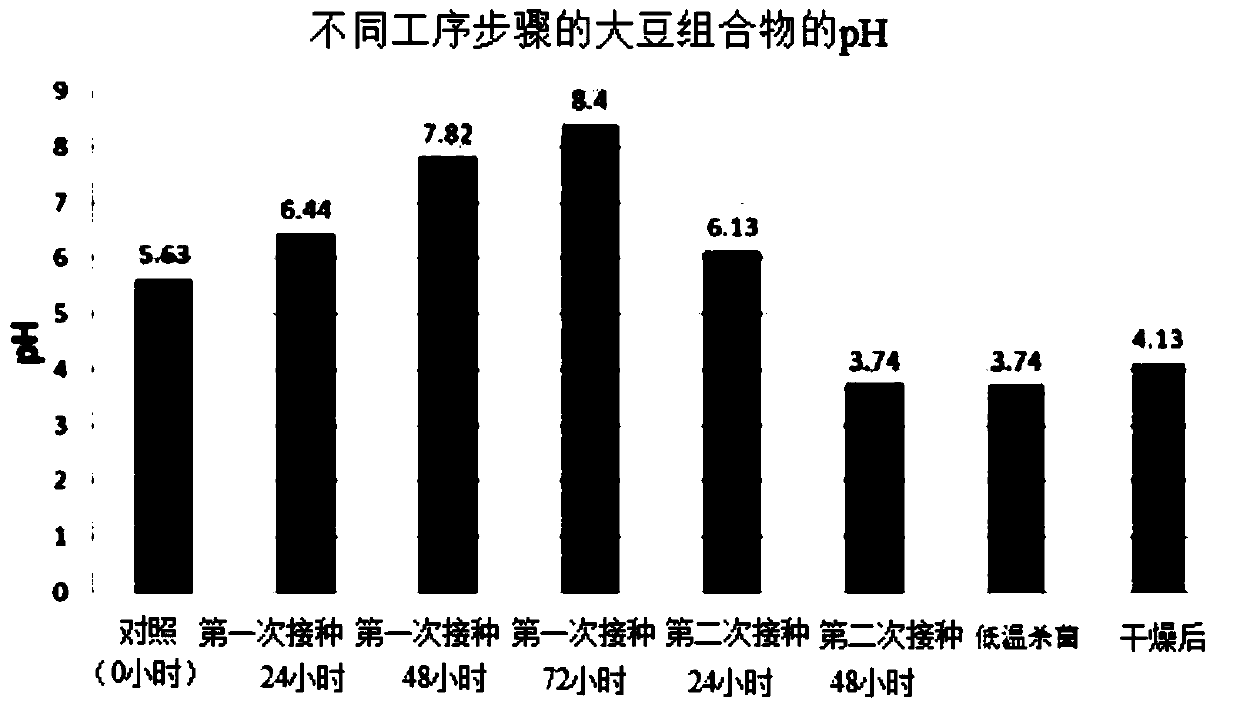

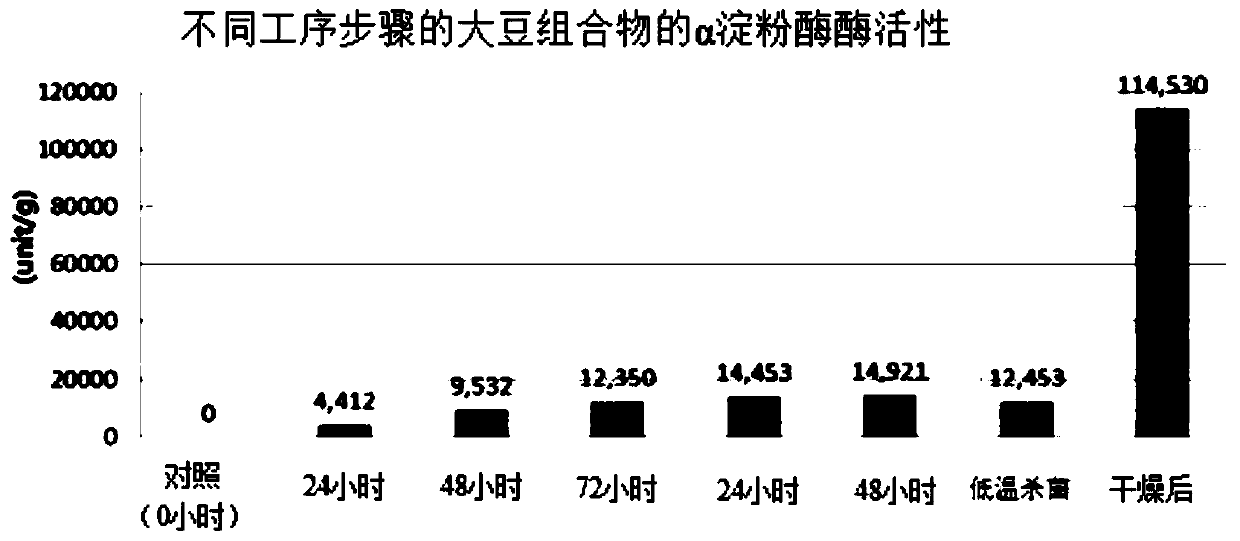

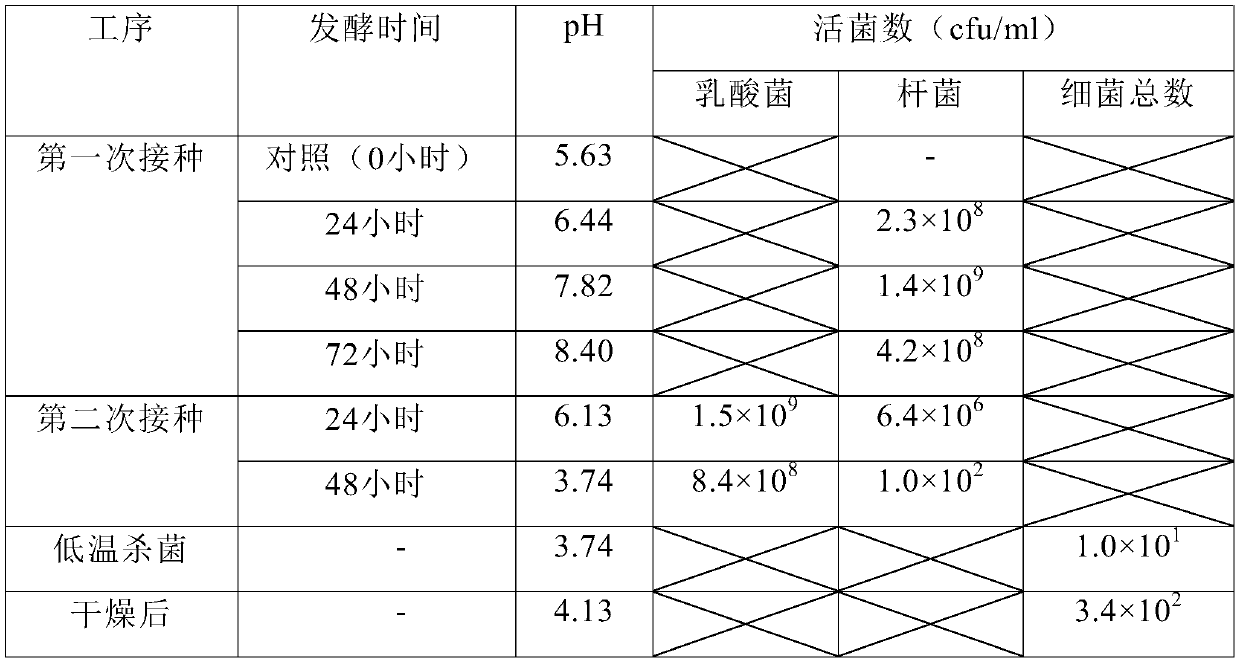

[0028] The preparation method of edible enzyme food utilizing Bacillus subtilis of the present invention is characterized in that, comprises: (1) preparation step, prepares the fermented raw material as fermentation object; Add 3 times to 10 times the amount of water to the prepared fermentation raw materials, and add 1×10 7 cfu / g to 1×10 9 cfu / g is inoculated with Bacillus subtilis for the first time, and fermented for 24 hours to 168 hours at a temperature of 35°C to 45°C to obtain the first fermentation product; (3) the second fermentation step, in the first fermentation product in, to 1 x 10 7 cfu / ml to 1×10 9cfu / ml is inoculated with lactic acid bacteria for the second time, and fermented at a temperature of 35°C to 45°C for 24 hours to 168 hours to obtain a second fermentation product; and (4) a low-temperature sterilization step, at a temperature of 50°C to 70°C Next, carry out low-temperature sterilization for 20 minutes to 40 minutes to the second fermentation prod...

preparation example 1

[0043] Preparation Example 1: Cultivation of Bacillus subtilis

[0044] The culture medium of Bacillus subtilis usually uses a nutrient medium (Nutrient broth), which is heat-sterilized for more than 15 minutes under the sterilization conditions of a conventional microbial culture medium at 121°C, and the inoculum size of Bacillus subtilis is 1×10 5 cfu / ml to 1×10 6 cfu / ml, cultivated at 35°C to 40°C for 12 hours to 18 hours, the number of viable bacteria of Bacillus subtilis after cultivation is 1×10 9 cfu / ml to 1×10 10 cfu / ml range, and the number of viable bacteria concentrated by centrifugation is 1×10 11 cfu / ml to 7×10 12 cfu / ml. When it is freeze-dried to use powdered Bacillus subtilis, generally 1% (v / w) to 10% (v / w) of the amount of water used in the powder composition is added, and the added Bacillus subtilis at this time The number of viable bacteria is 1×10 7 cfu / g to 1×10 9 cfu / g.

preparation example 2

[0045] Preparation Example 2: Cultivation of Lactic Acid Bacteria

[0046] The culture medium of lactic acid bacteria usually uses MRS medium, which is heat sterilized for more than 15 minutes under the sterilization conditions of conventional microbial culture medium at 121°C, and the inoculation amount of lactic acid bacteria is 1×10 5 cfu / ml to 1×10 6 cfu / ml, cultivated at 40°C to 45°C for 12 hours to 18 hours, the number of live bacteria of the cultured lactic acid bacteria is 1×10 9 cfu / ml to 1×10 10 The range of cfu / ml, and the number of live bacteria of lactic acid bacteria concentrated by centrifugal separation is 1×10 11 cfu / ml to 5×10 12 cfu / ml. When it is freeze-dried and powdered lactic acid bacteria are used, usually 1% (v / w) to 10% (v / w) of the amount of water used in the powder composition is added. The number of bacteria is 1×10 7 cfu / g to 1×10 9 cfu / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com