Composite light spot laser system based on optical fiber output laser modules and machining head

A laser module and laser system technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult laser optical system design, expensive high-power beam combiner, and low device reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

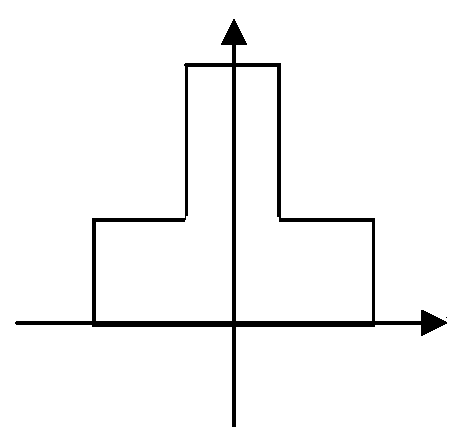

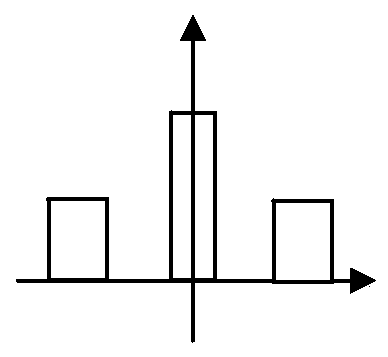

[0060] Embodiment 1: According to the technical scheme of the laser system based on multiple optical fiber output laser modules proposed by the present invention, in a certain embodiment of the present invention, it is necessary to realize the light synthesis of 49 optical fiber output laser modules into a light spot structure, and the light spot is required 1.8 mm in diameter. The system uses Figure 4A The structure of 7 collimating lenses and 1 focusing lens is shown, the optical axes of the 7 collimating lenses are parallel, the focal lengths of the 7 collimating lenses are the same, and the front focal planes coincide, the optical axes of the focusing lens FL and the collimating lens The optical axis is parallel to and coincides with the optical axis of the collimating lens in the center; the output power of the semiconductor laser module with a wavelength of 915 nanometers is 120 watts, the output fiber core diameter is 105 microns, the cladding diameter is 125 microns, ...

Embodiment 2

[0061] Embodiment 2: According to the technical scheme of the laser system based on multiple optical fiber output laser modules proposed by the present invention, in a certain embodiment of the present invention, a spot with high power in the central area and low power in the edge area is required, and the Figure 4A In the shown structure of 7 collimating lenses and 1 focusing lens, the optical axes of the 7 collimating lenses are parallel, the optical axis of the focusing lens FL is parallel to the optical axis of the collimating lens, and the light beam of the collimating lens located in the center Axis coincidence; In this embodiment, 7 fiber output laser modules are fiber lasers with a wavelength of 1064 nanometers, power 500 to 1000 watts, the core diameter of each module output fiber is 20 microns, the numerical aperture is 0.06, and the fiber cladding diameter 400 microns. Among the 7 collimating lenses, 6 have a focal length of 50 mm, 1 has a focal length of 25 mm, th...

Embodiment 3

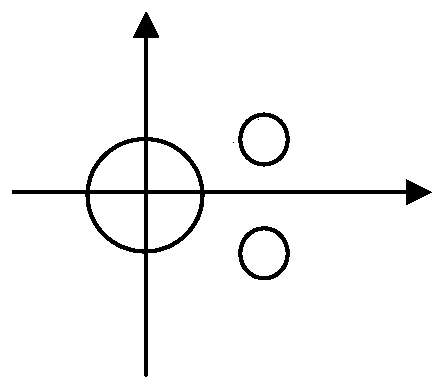

[0063] Embodiment 3: According to the technical scheme of the laser system based on multiple optical fiber output laser modules proposed by the present invention, in a certain embodiment of the present invention, a light spot with a sheet-like converging structure is required, and the collimating lens and the converging lens in the optical path use Figure 7 In the structure shown, 6 lenses are arranged one-dimensionally in one plane, the optical axes of the 6 lenses are parallel, the focal lengths of the 6 lenses are the same, and the front focal planes coincide, the optical axis of the focusing lens FL is parallel to the optical axis of the collimating lens , the distribution center of the six collimating lenses coincides with the optical axis of the focusing lens. In this embodiment, the 6 fiber output laser modules are fiber lasers with a wavelength of 1064 nanometers and a power of 500 to 1000 watts. The core diameter of the output fiber of each module is 20 microns, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com