Combined closed cooling tower

A closed cooling tower and composite technology, which is applied in water shower coolers, direct contact heat exchangers, heat exchange equipment, etc. Problems such as poor load adjustment performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

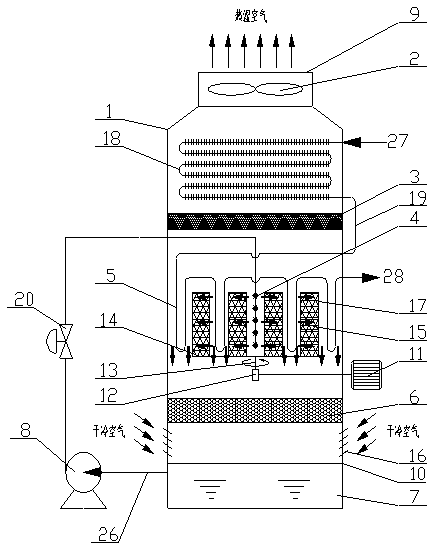

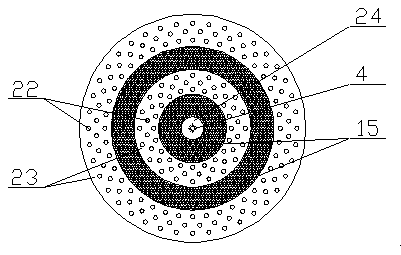

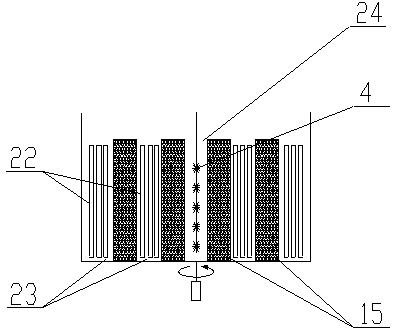

[0046] use figure 1 Structure closed cooling tower, the heat exchange tube assembly is divided into dry and wet sections, the heat exchange tube assembly is made of φ20×1mm seamless steel pipe, and the outer wall of the dry section heat exchange tube is equipped with fins, accounting for 1 / of the total length of the heat exchange tube 3. The heat exchange tube in the wet section is a smooth tube, accounting for 2 / 3 of the total length of the heat exchange tube. The lower part of the dry section heat exchange tube is equipped with a water collection demister, and the lower part of the water collection demister is a wet section heat exchange tube. The wet section heat exchange tube and the bed form a "central cavity-bed-heat exchange tube-bed - 2 groups of heat exchange tubes are arranged in a staggered manner, using Figure 4 , Figure 5 Horizontal circular coiled form. The bed layer is made of stainless steel orifice plate corrugated packing, the height is 600mm, and the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com