Modified multi-walled carbon nanotube, preparation method thereof and method for removing nickel ions in water

A technology of multi-walled carbon nanotubes and nickel ions, which is applied in the preparation of modified multi-walled carbon nanotubes, the fields of modified multi-walled carbon nanotubes and the removal of nickel ions in water, can solve the problem of high cost, low processing efficiency and low content. The water treatment effect of the concentration of nickel ions is not good, so as to achieve the effect of low cost, simple operation and improving the ability of adsorbing heavy metal ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the modified multi-walled carbon nanotube according to the embodiment of the present invention comprises the following steps:

[0035] Prepare potassium permanganate solution, specifically, take a certain quality of potassium permanganate and place it in a certain volume of deionized water to form a certain concentration of potassium permanganate solution;

[0036] The multi-walled carbon nanotubes and the potassium permanganate solution are placed in a container, in other words, the multi-walled carbon nanotubes and the potassium permanganate solution are mixed, wherein the container is such as an Erlenmeyer flask;

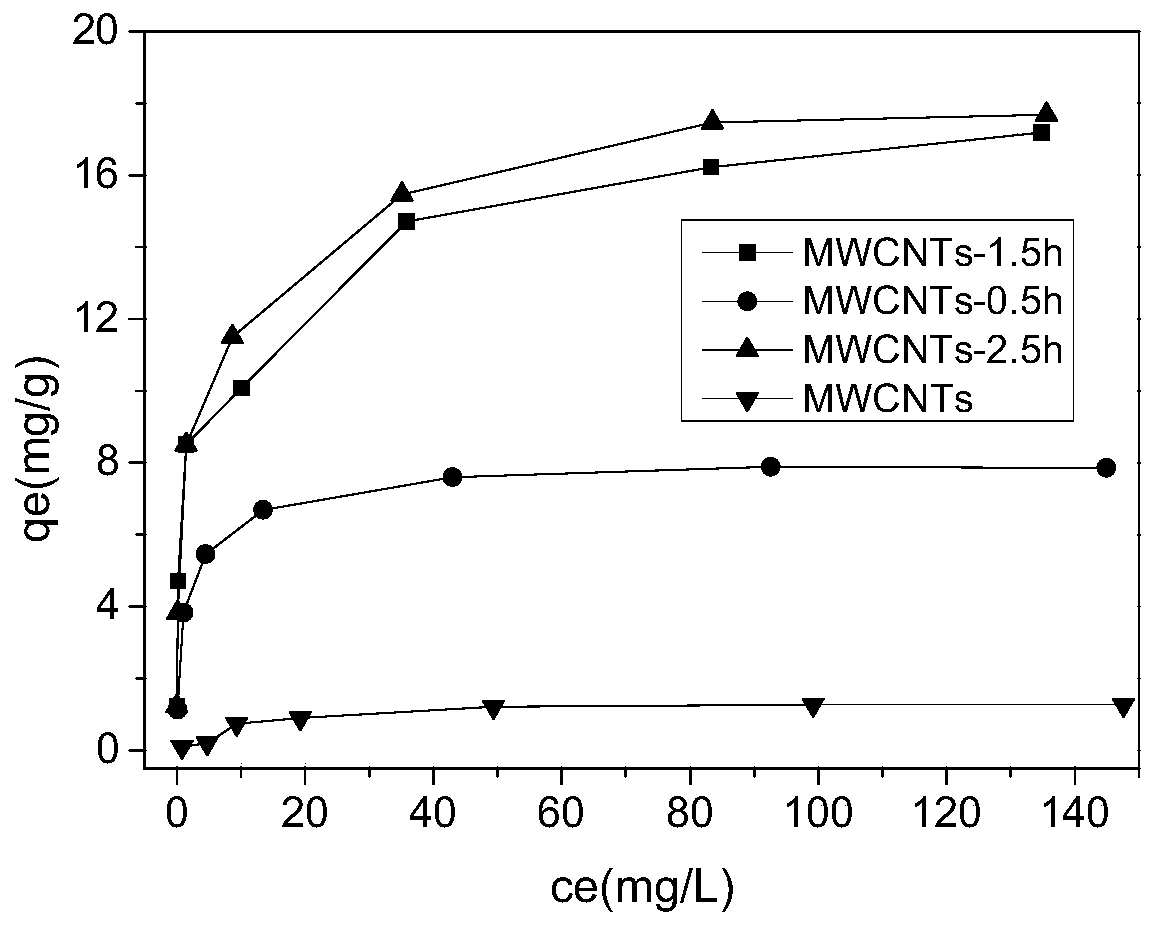

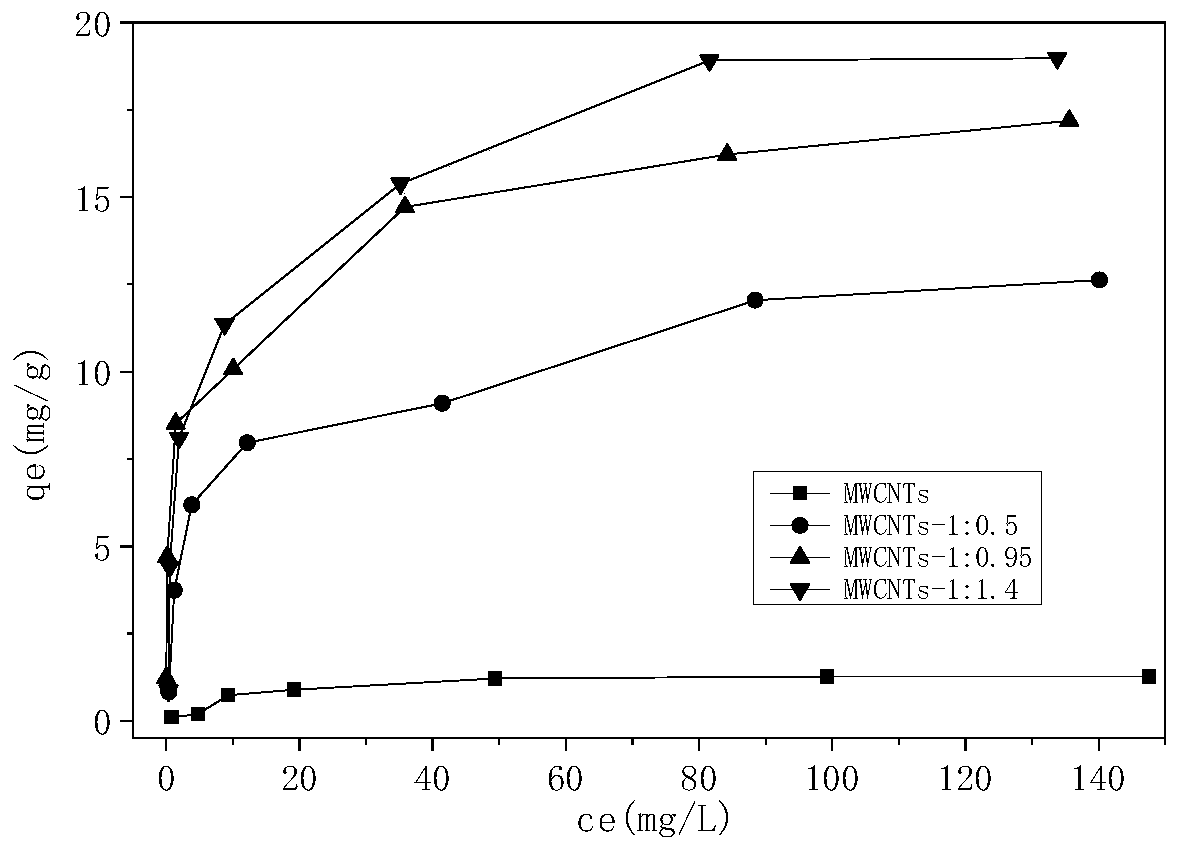

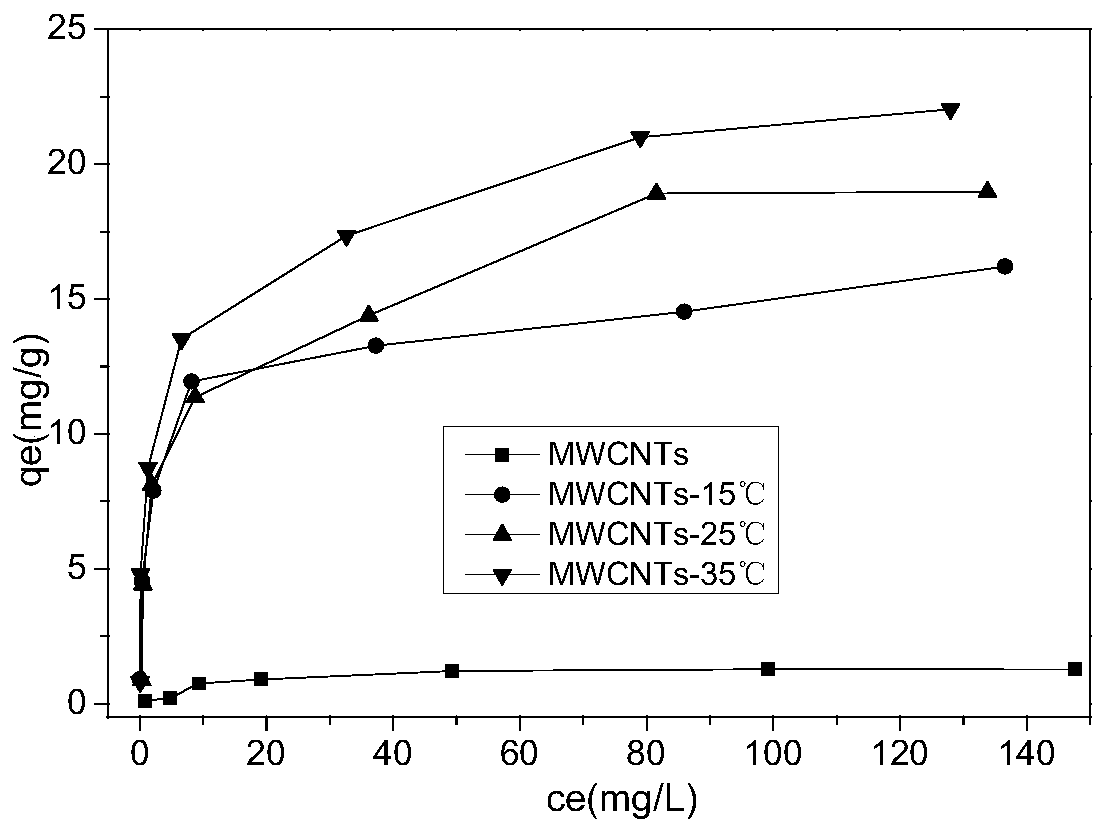

[0037] ultrasonically oscillating the container at a first preset temperature for a first preset time to react the multi-walled carbon nanotubes and the potassium permanganate solution, in other words, the multi-walled carbon nanotubes and the potassium permanganate solution are mixed for an ultrasonic reaction , and the reaction ...

Embodiment 1

[0070] Potassium permanganate solution was prepared so that the mass ratio of multi-walled carbon nanotubes to potassium permanganate was 1:0.95. Weigh 1.5 g of dried multi-walled carbon nanotubes, put them in a 250 ml Erlenmeyer flask, and add 250 ml of the above potassium permanganate solution into the 250 ml Erlenmeyer flask. Seal the Erlenmeyer flask containing the multi-walled carbon nanotubes and potassium permanganate solution with a sealing film. The sealed Erlenmeyer flask was ultrasonically oscillated at 25° C. for 2.5 h so that the multi-walled carbon nanotubes and the potassium permanganate solution undergo an ultrasonic reaction. After the ultrasonic reaction, use a microfiltration membrane to filter the reacted multi-walled carbon nanotubes, then wash the reacted multi-walled carbon nanotubes with deionized water and put them in a drying oven at a constant temperature of 60°C for 10 hours. , dried and ground to obtain modified multi-walled carbon nanotubes, reco...

Embodiment 2

[0073] Potassium permanganate solution was prepared so that the mass ratio of multi-walled carbon nanotubes to potassium permanganate was 1:0.95. Weigh 1.5 g of dried multi-walled carbon nanotubes, put them in a 250 ml Erlenmeyer flask, and add 250 ml of the above potassium permanganate solution into the 250 ml Erlenmeyer flask. Seal the Erlenmeyer flask containing the multi-walled carbon nanotubes and potassium permanganate solution with a sealing film. The sealed Erlenmeyer flask was vibrated ultrasonically at 25° C. for 1.5 h so that the multi-walled carbon nanotubes and the potassium permanganate solution undergo an ultrasonic reaction. After the ultrasonic reaction, use a microfiltration membrane to filter the reacted multi-walled carbon nanotubes, then wash the reacted multi-walled carbon nanotubes with deionized water and put them in a drying oven at a constant temperature of 60°C for 10 hours. , dried and ground to obtain modified multi-walled carbon nanotubes, denote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com