A kind of anti-oxidation casting method of B30 alloy ingot

A technology of alloy ingot and casting method, applied in the field of anti-oxidation casting of B30 alloy ingot, can solve problems such as worker's health injury, safety hazard, scattering, etc., and achieve the effects of improving comprehensive performance, reducing safety accidents, and preventing hot brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

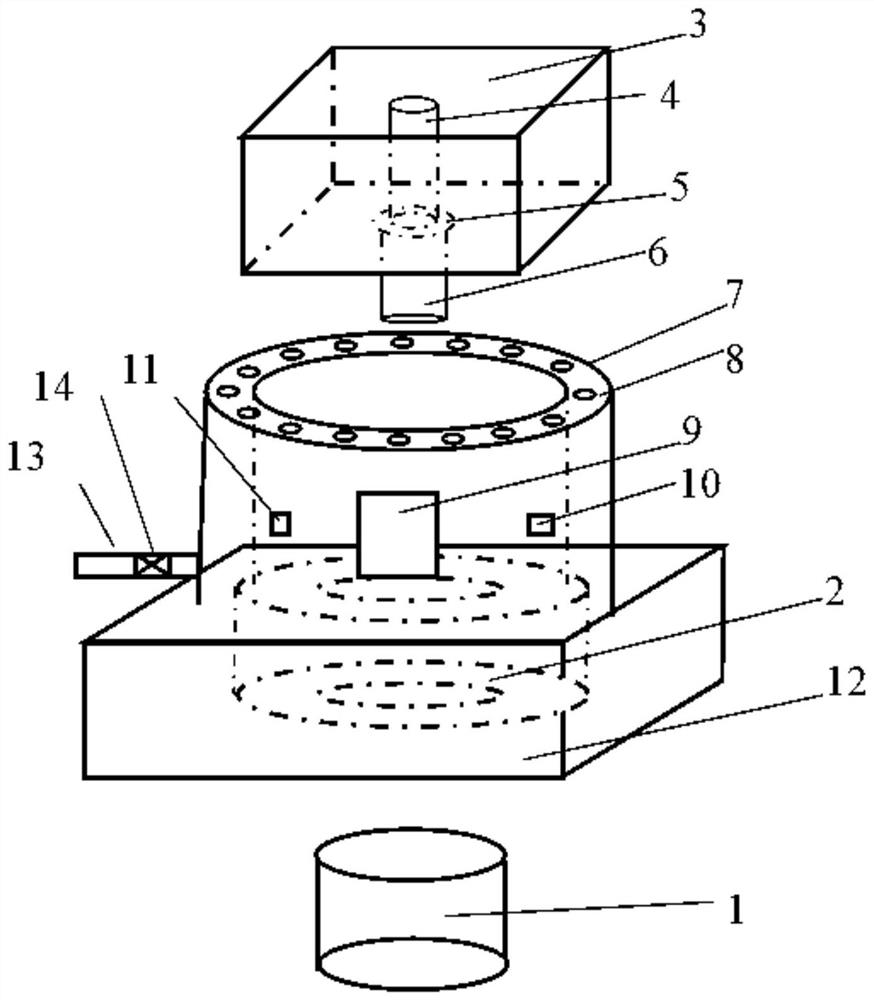

[0026] Such as figure 1 As shown, the anti-oxidation casting equipment for B30 alloy ingots includes a hearth, an ignition device and a crystallizer. The hearth is arranged above the ignition device. The hearth includes a furnace head 3; 6; the ignition device includes a furnace pan 7 arranged on the top of the ignition device, and a plurality of fire distributor nozzles 8 are arranged on the upper surface of the furnace pan 7, and the adjacent fire distributor nozzles 8 are spaced at 5-10mm intervals, and are distributed in a ring to form a firearm; the ignition device furnace The plate 7 near the crystallizer 2 is provided with a high-temperature-resistant glass window 9; the temperature-measuring probe 10 and the oxygen concentration detector 11 are respectively installed on both sides of the high-temperature-resistant glass 9 window position, and the furnace plate 7 is connected to the crystallizer mold through a quick-loading structure. The base 12 is sealed with a high t...

Embodiment 2

[0028] A method for anti-oxidation casting of B30 alloy ingot, comprising the following steps:

[0029] 1) Crystallizer preparation: raise the dummy table (1) into the cavity of mold 2, and overlap with the bottom of mold 2 by 20-40 mm, and use asbestos rope to fill the mold 2 and dummy ingot layer by layer in the same direction The gap between the tables 1; the crystallizer 2 is a graphite crystallizer with a height of 200-250mm and an inner diameter of 182-184mm;

[0030] 2) Ironing furnace head: tilt the furnace platform so that the copper liquid immerses the furnace head, control the temperature of the furnace head to 1200-1350 ° C, melt the residual metal on the stopper 4, the bottom bowl 5, and the pouring pipe 6 to ensure that the ingot is cast The normal rotation of the stopper rod 4, the stopper rod 4 and the bottom bowl 5 are in good condition, and the copper liquid flow can be adjusted normally; the stopper rod 4, the bottom bowl 5, and the pouring pipe 6 are all ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com