A current-assisted thermal field friction stir welding method for titanium alloy material butt joint

A technology of friction stir welding and titanium alloy, which is applied in the direction of non-electric welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of unstable weld structure, low room temperature plasticity and defects, etc. Excellent performance and good forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0032] (1) Two pieces of Ti2AlNi titanium alloy plates are obtained by wire cutting, the thickness of the Ti2AlNi titanium alloy plates is 5mm, and the two Ti2AlNi titanium alloy plates use silicon carbide sandpaper 180#, silicon carbide sandpaper 400#, and silicon carbide sandpaper 800# for aluminum alloy plates The surface is polished until the surface of the titanium alloy plate is bright, and then the titanium alloy plate is ultrasonically cleaned in acetone for 5 minutes to 10 minutes to obtain a pretreated titanium alloy plate.

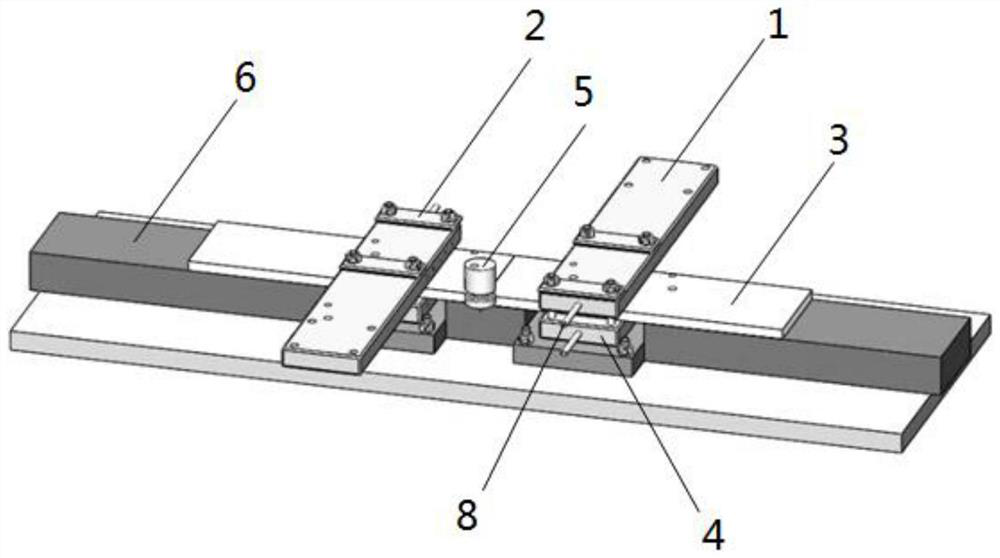

[0033] (2) Install a heating and protective gas output device on the side of each pretreated titanium alloy plate close to the welding area, and place two pretreated titanium alloy plates equipped with a heating and protective gas output device on the Bakelite 6 after butt joint, Then the whole is fixed on the area to be welded by the friction stir welding machine.

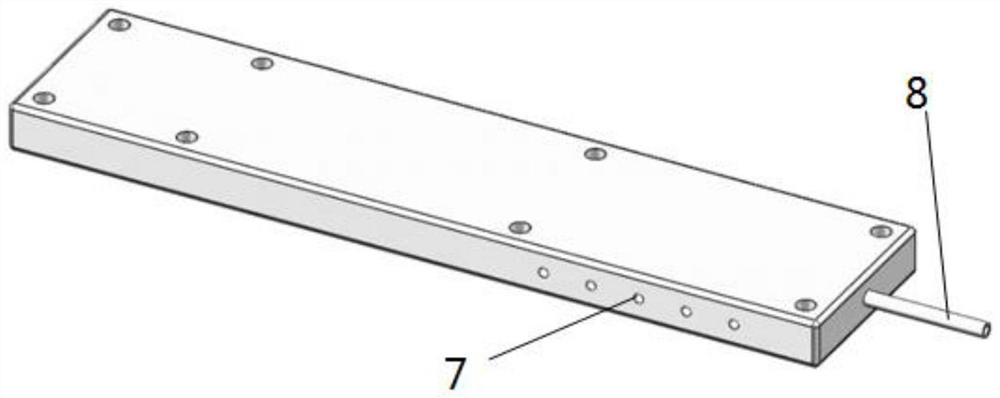

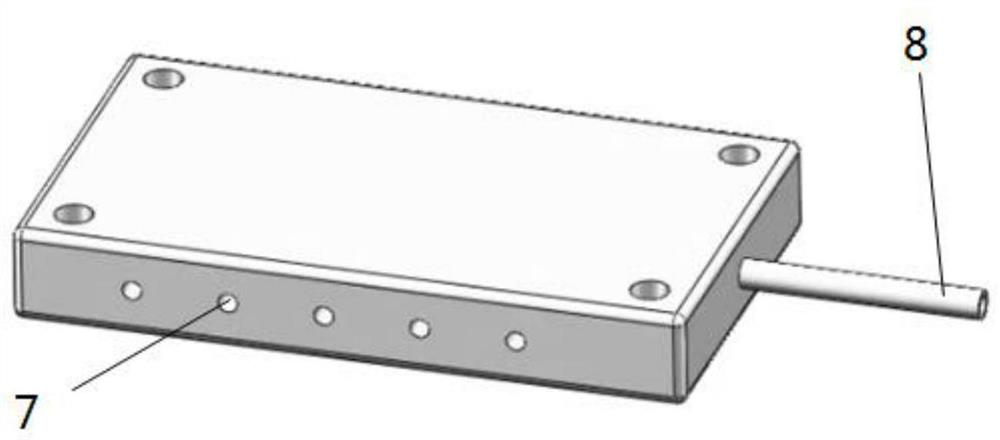

[0034] Among them, the heating and protective gas output device includes a copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com