Entrained-flow bed coal gasification fine slag black water multi-energy-field synergistic efficient dehydration method

A coal gasification and entrained bed technology, applied in the direction of light water/sewage treatment, climate sustainability, greenhouse gas reduction, etc., can solve the problems of high moisture content in filter cakes, low dehydration efficiency of fine slag and black water, and improve dehydration time, reducing soil and groundwater pollution problems, and reducing the effect of moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

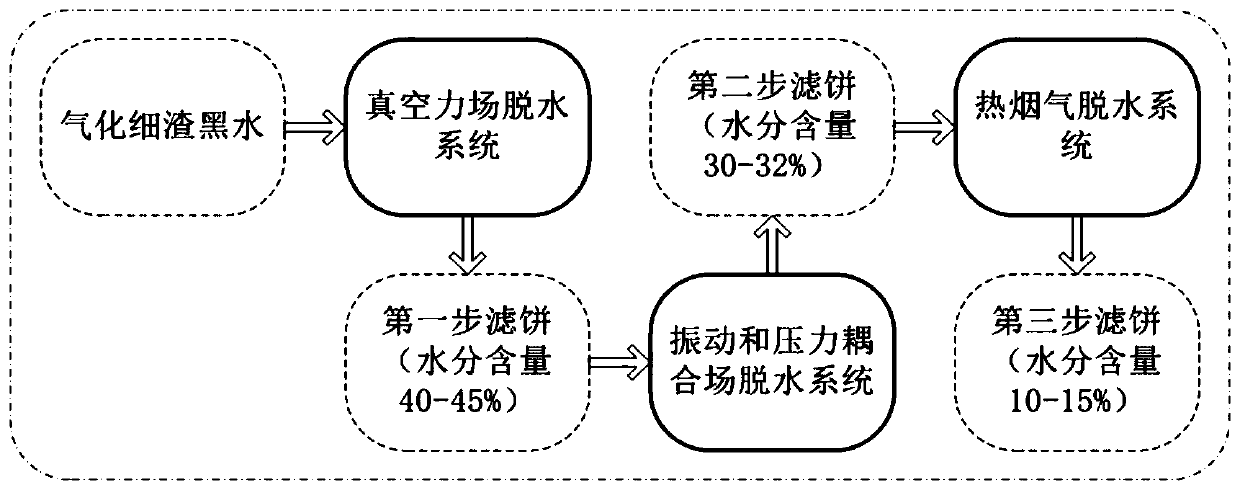

[0032] An entrained bed coal gasification fine slag black water multi-energy field synergistic high-efficiency dehydration method comprises the following steps:

[0033] Step a, the gasified fine slag obtained from the gasifier is processed by a Venturi scrubber to obtain black water, and the black water is concentrated in the concentration pool to provide raw materials for the next step of dehydration;

[0034] Step b, when the mass content of gasification fine slag in the black water is controlled at 3-20%, the black water is transported to the dehydration section;

[0035] Step c, pumping the gasified fine slag black water to the vacuum force field system, the vacuum degree is controlled above 0.08MPa, and a filter cake with a thickness of 3-6mm is obtained, and the moisture content of the filter cake is 40-45%;

[0036] Step d, transport the filter cake obtained in step c to the vibration and pressure coupling force field system for further dehydration through a belt conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com