Preparation method of guanidinoacetic acid

A technology of guanidinoacetic acid and guanidinoethanol, which is applied in the preparation field of guanidinoacetic acid, can solve the problems of increased cost of guanidinoacetic acid, complicated purification process, many side reactions, etc., and achieves high utilization rate of raw materials, improved reaction efficiency, production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

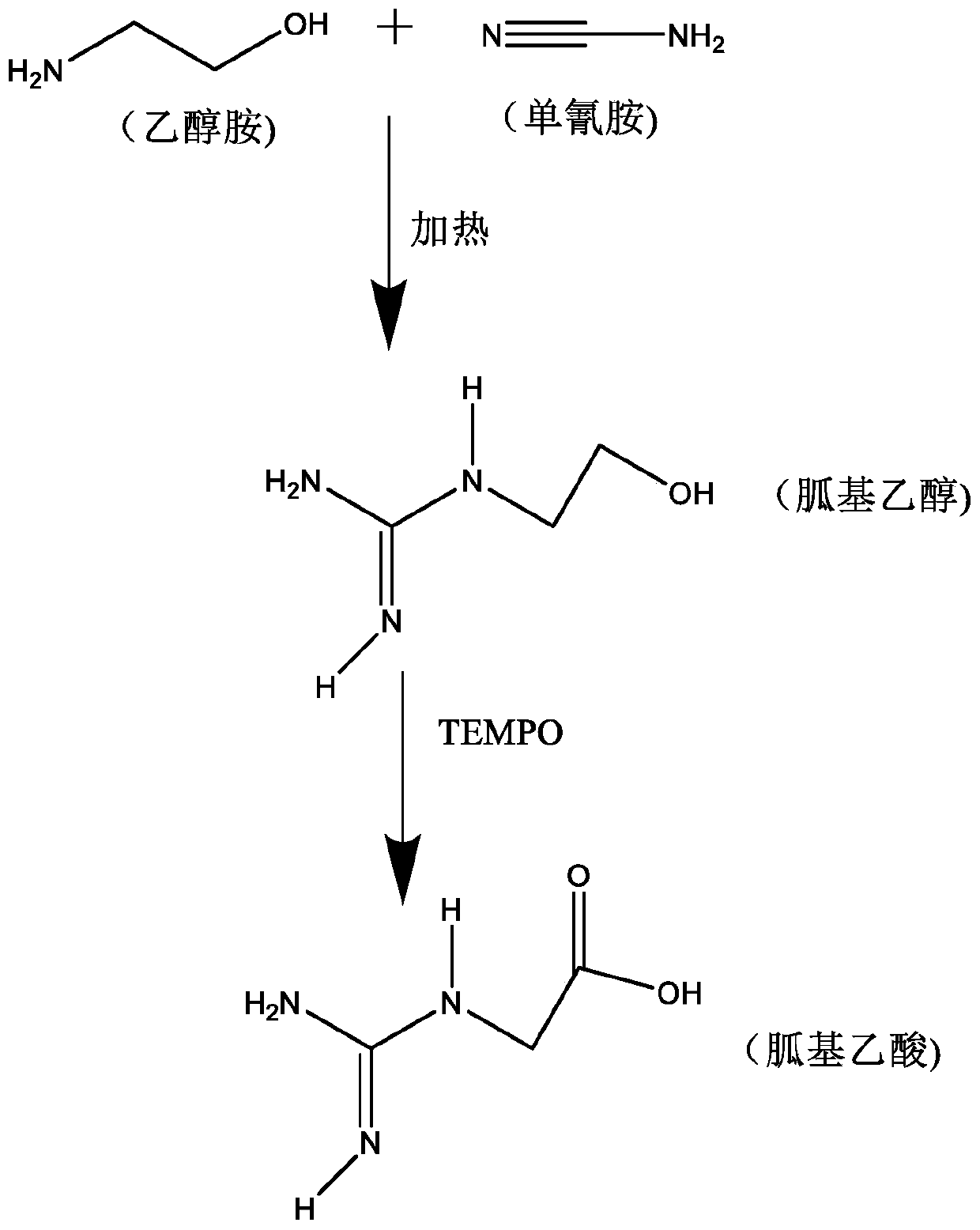

[0034] A preparation method of guanidinoacetic acid, specifically comprising the following steps:

[0035] Step 1: Add 50 g of ethanolamine and 20 g of water into the reactor, and stir to raise the temperature to 40°C.

[0036] Step 2: After the temperature rise in step 1 is completed, add 80 g of an aqueous cyanamide solution whose mass to water volume ratio of cyanamide is 0.4 to the reactor, continue to stir after the aqueous cyanamide solution is added dropwise, and React for 2h to obtain guanidinoethanol.

[0037] Step 3: Add 1 g of catalyst TEMPO to the reaction kettle of guanidinoethanol obtained in step 2, continue to stir and continue to react at this temperature for 1 h, and obtain the crude product of guanidinoacetic acid after filtering while hot.

[0038] Step 4: Dissolve the crude guanidinoacetic acid obtained in step 3 in an aqueous ethanol solution with a volume ratio of 95% before cooling, recrystallize the crude guanidinoacetic acid in aqueous ethanol, and o...

Embodiment 2

[0041] A preparation method of guanidinoacetic acid, specifically comprising the following steps:

[0042] Step 1: Add 50 g of ethanolamine and 50 g of water into the reactor, and stir to raise the temperature to 70°C.

[0043] Step 2: After the temperature rise in step 1 is completed, add 55 g of cyanamide aqueous solution whose mass to water volume ratio of cyanamide is 0.6 to the reactor, and continue to stir after the cyanamide aqueous solution is added dropwise and at this temperature After 4 hours of reaction, guanidinoethanol was obtained.

[0044] Step 3: Add 15 g of catalyst TEMPO to the reaction kettle of guanidinoethanol obtained in step 2, continue to stir and continue to react at this temperature for 2 hours, and obtain the crude product of guanidinoacetic acid after filtering while hot.

[0045] Step 4: Dissolve the crude guanidinoacetic acid obtained in step 3 in an aqueous ethanol solution with a volume ratio of 95% before cooling, recrystallize the crude guan...

Embodiment 3

[0048] A preparation method of guanidinoacetic acid, specifically comprising the following steps:

[0049] Step 1: Add 50 g of ethanolamine and 35 g of water into the reactor, and stir to raise the temperature to 50°C.

[0050] Step 2: After the temperature rise in step 1 is completed, add 65 g of cyanamide aqueous solution whose mass to water volume ratio of cyanamide is 0.5 to the reactor, continue to stir after the cyanamide aqueous solution is added dropwise and at this temperature React for 2h to obtain guanidinoethanol.

[0051] Step 3: Add 10 g of catalyst TEMPO to the reaction kettle of guanidinoethanol obtained in step 2, continue to stir and continue to react at this temperature for 2 hours, and obtain the crude product of guanidinoacetic acid after filtering while hot.

[0052] Step 4: Dissolve the crude guanidinoacetic acid obtained in step 3 in an aqueous ethanol solution with a volume ratio of 95% before cooling, recrystallize the crude guanidinoacetic acid in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com