Method for biological treatment of nitrogen in wastewater by nitritation

A biological treatment and nitrosation technology, applied in the adjustment methods of biological treatment, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of unoptimized and difficult to implement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1 : Establishment and maintenance of nitrosation by NOB inhibition in a continuously fed nitrosation-denitritation reactor

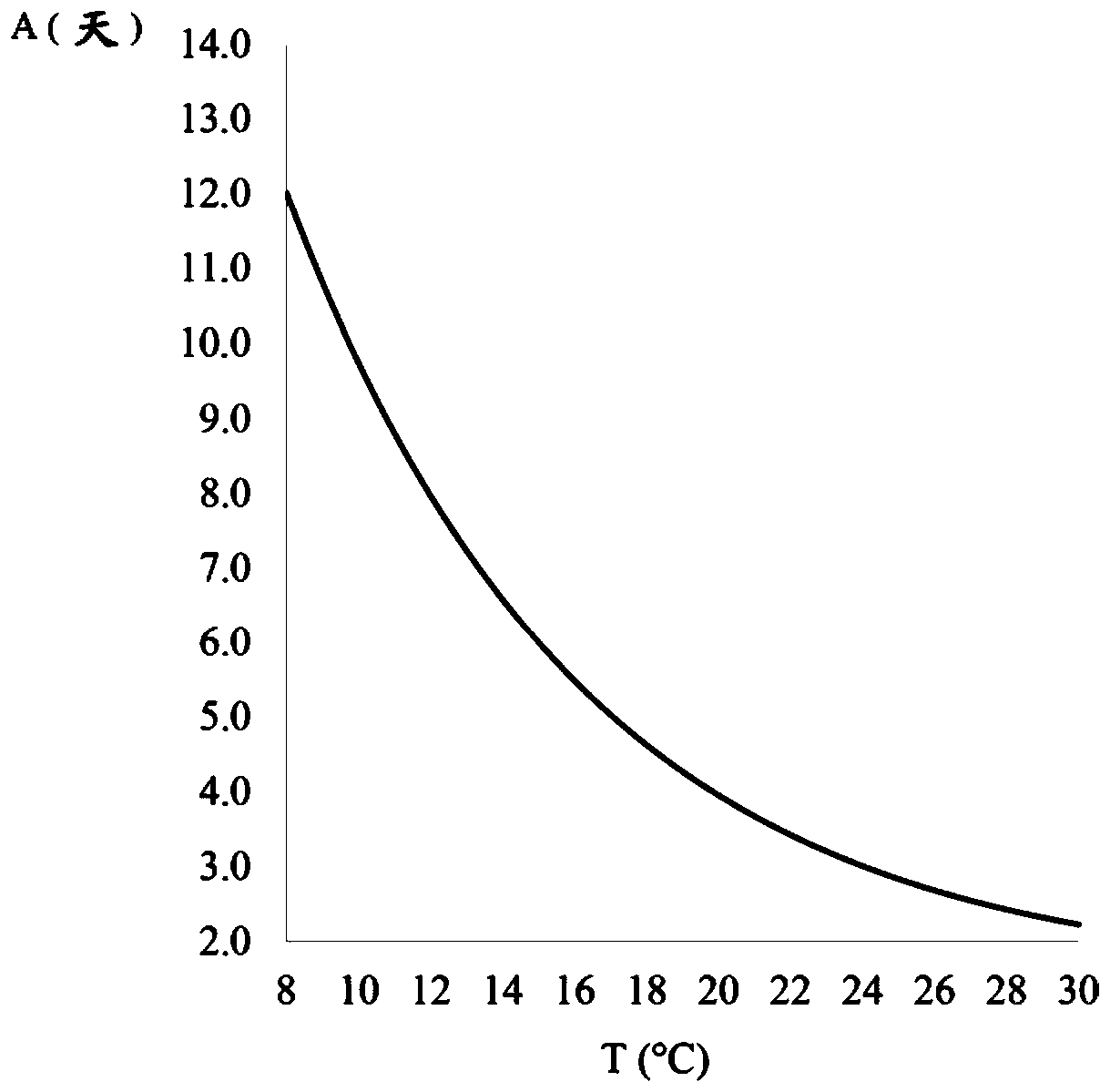

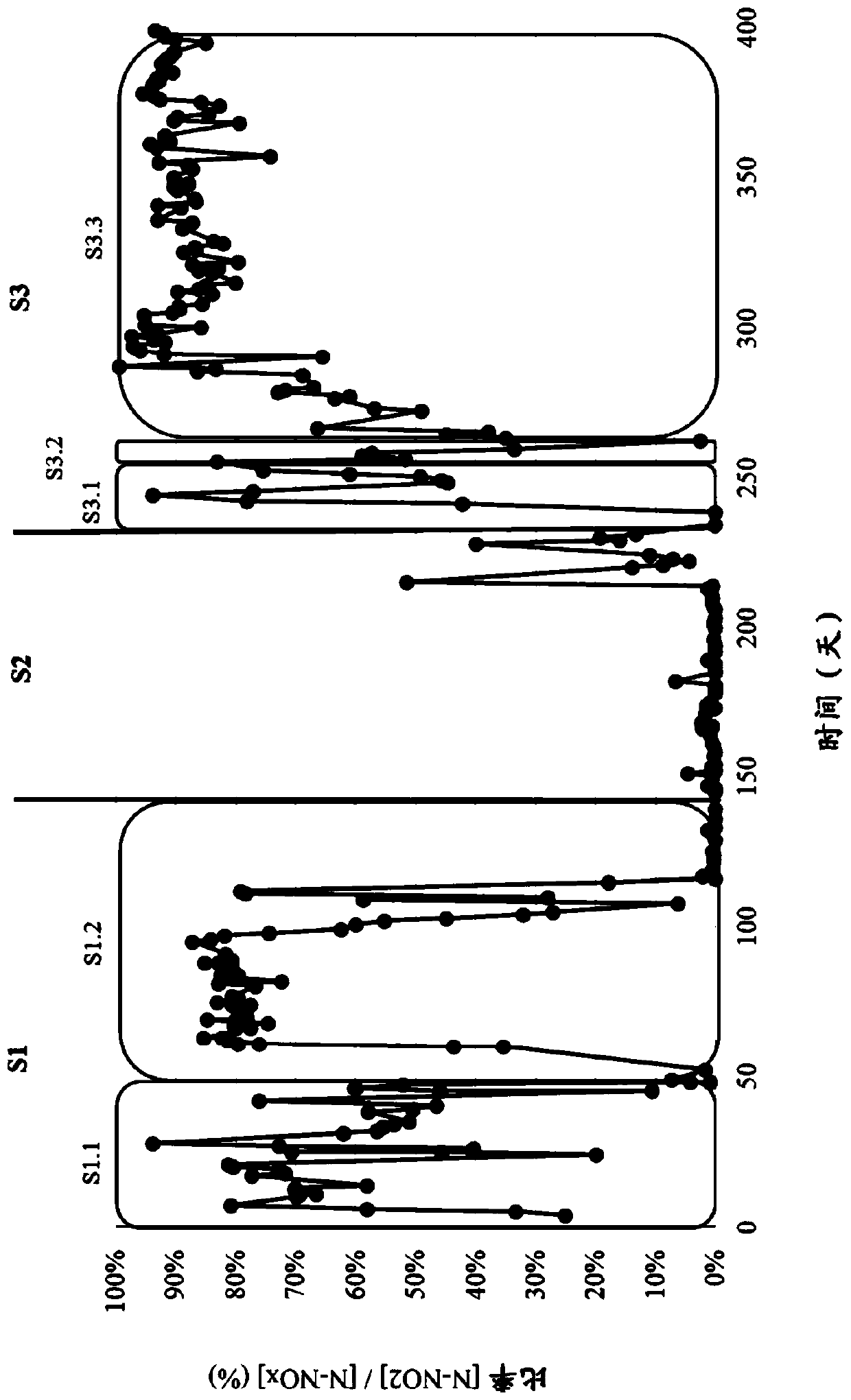

[0065] The system for the biological treatment of wastewater nitrogen consists of two 4 and 8.9m 3 The activated sludge bioreactor and 10.6m 3 The clarifier consists of a continuous supply of 2m 3 / h pre-treated municipal wastewater to remove colloidal and particulate carbon. The bioreactor is equipped with a mixer, an aeration system, a device for measuring and regulating the concentration of dissolved oxygen, and a device for measuring the concentration of nitrite, nitrate and ammonium. Ammonium nitrogen processing was initiated without prior inoculation of the bioreactor. The effects of dissolved oxygen concentration during the aeration phase, nitrite elimination prior to the aeration phase, and the effective life of the aerated sludge over time on NOB inhibition and establishment of nitrosation in the reactor were tested according...

Embodiment 2

[0075] Example 2 : Establishment and maintenance of nitrosation by NOB inhibition in a batch-fed SBR nitrosation-denitritation reactor

[0076] The bioreactor is based on 13.7m 3 / d SBR type activated sludge reactor intermittently fed with pre-treated municipal wastewater to remove colloidal and particulate carbon and constant level of suspended solids. The dimensions of the reactor are as follows: diameter: 1.2m; surface area: 1.13m 3 ;Total height: 4m; Water level: 3.18m; Volume: 3.6m 3 . The reactor is equipped with a mixer; an aeration system; means for measuring and regulating the dissolved oxygen concentration and means for measuring the concentration of nitrite, nitrate and ammonium. Nitrogen treatment was performed by sequentially performing a continuous cycle of the following four steps: simultaneous feed and discharge step for 60 min, anoxic step for 30 min, aeration step for 60 min, and decanting step for 60 min.

[0077] The effects of dissolved oxygen concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com