Bauxite dissolution process

A bauxite and process technology, applied in the field of bauxite dissolution process, can solve the problems of high cost, unfavorable economic performance, waste of alumina and alkali, and increased production cost, so as to improve the dissolution effect, improve recovery rate, and improve Effect of silicon volume index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

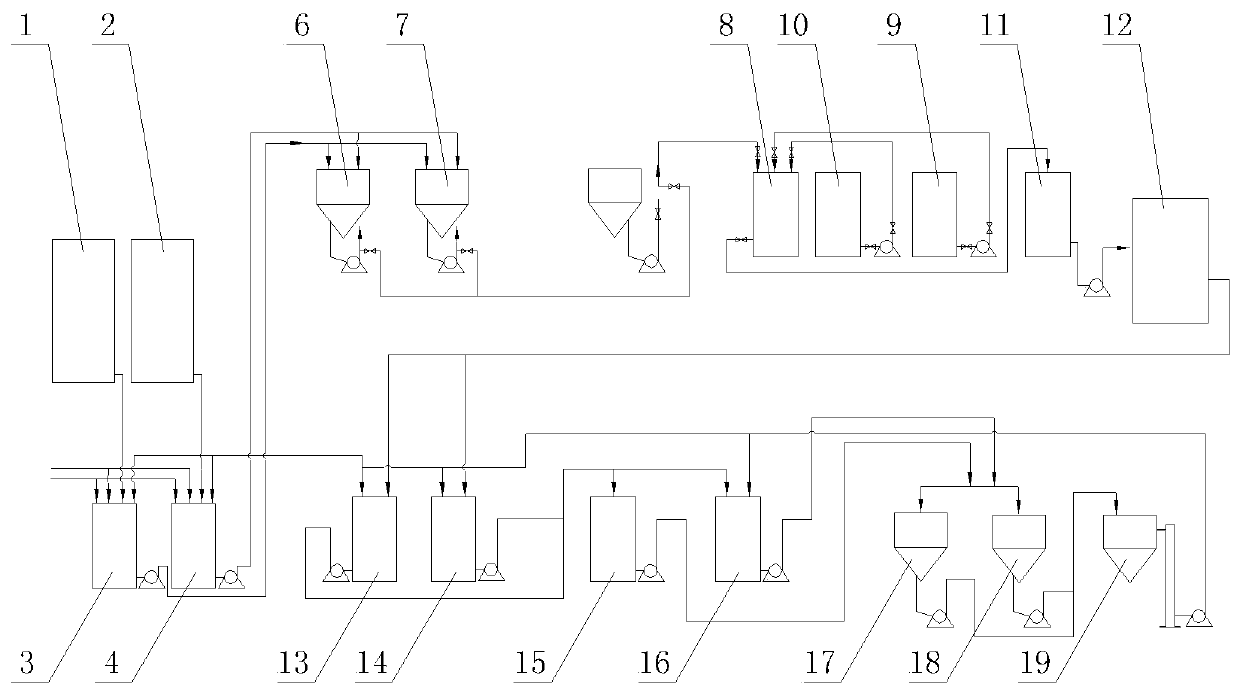

[0028] A kind of leaching process of bauxite, comprising such as figure 1 Steps shown:

[0029] Step 1: Select bauxite and caustic lye to mix and grind to make slurry, and obtain a stripping slurry from seven stripping units 1 and eight stripping units 2 after heating. The stripping slurry mainly includes sodium aluminate solution and red mud , the temperature of the one-stage stripping pulp is between 120-140°C, and the stripping temperature in this embodiment is 120°C. The ore quality of bauxite is shown in the table below:

[0030]

[0031] Step 2: After entering the No. 1 post-dissolution tank 3 and No. 2 post-dissolution tank 4, the one-stage stripping pulp is mixed with the stripping pulp produced by the one-stage stripping and diluted with sintering crude liquid, and transported through the pipeline by a slurry pump of model 150LZ-500JM3 Settling tank No. 1 in the third phase and No. 2 settling tank 7 in the third phase are settled and separated to obtain a section...

Embodiment 2

[0038] The extraction of alumina from bauxite by the Bayer process includes two processes, one is the dissolution described in Example 1, and the second is decomposition, that is, adding hydroxide to the obtained sodium aluminate solution under the condition of dilution and cooling Aluminum acts as a seed crystal to decompose and precipitate aluminum hydroxide. The current common treatment method is to directly add the seed crystals to the filter cake tank and mix them with sodium aluminate solution, but the particle size of the seed crystals is relatively large, and the mixing effect is not good.

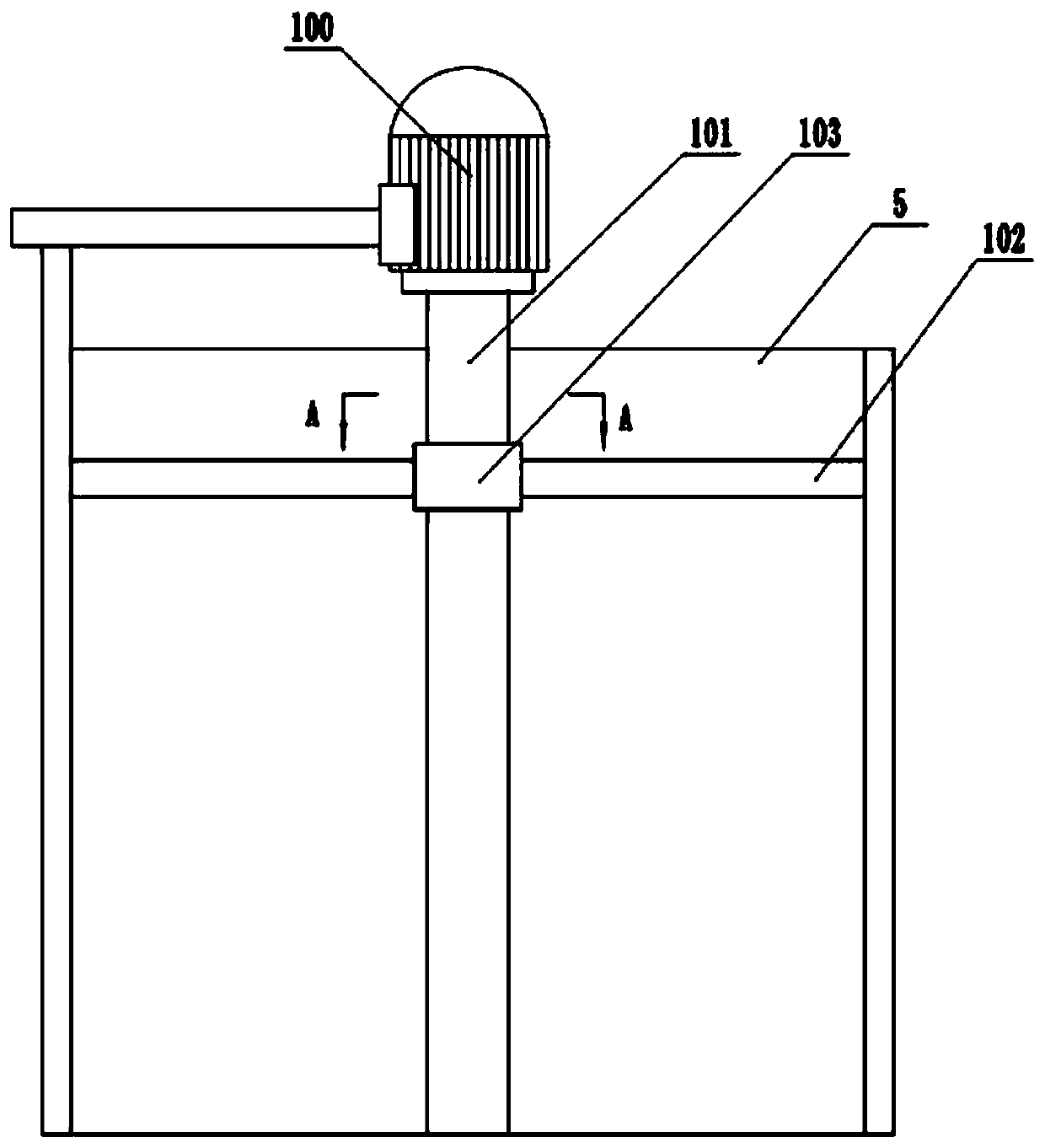

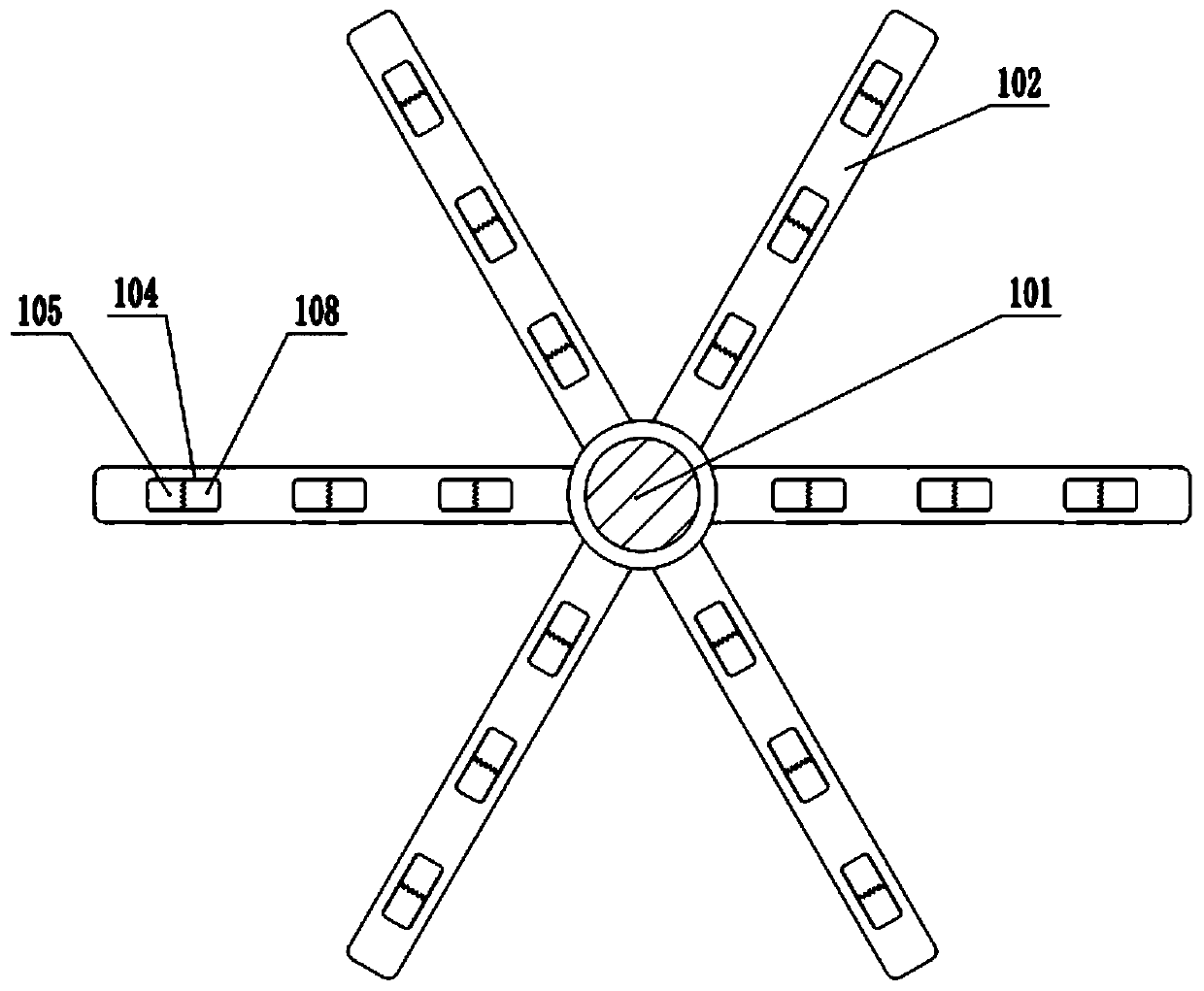

[0039] Based on this, if figure 2 As shown, frame and stirring mechanism are set in filter cake tank 5, and stirring mechanism comprises motor 100, stirring shaft 101 and stirring blade 102, and the model of motor 100 is MR-J2S-100A, and motor 100 is fixed on the frame, The output shaft of the motor 100 is arranged vertically downward, the stirring shaft 101 is connected in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com