A kind of 3D printing marine titanium alloy and its preparation method

A 3D printing and titanium alloy technology, which is applied in the field of 3D printing marine titanium alloy and its preparation, can solve the problems of poor performance and surface quality of titanium alloy materials, inability to meet the use requirements of high-performance and complex titanium alloy components, and inability to meet the use requirements. Achieve excellent seawater corrosion resistance and welding performance, excellent 3D printing laser forming performance, broad application prospects and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

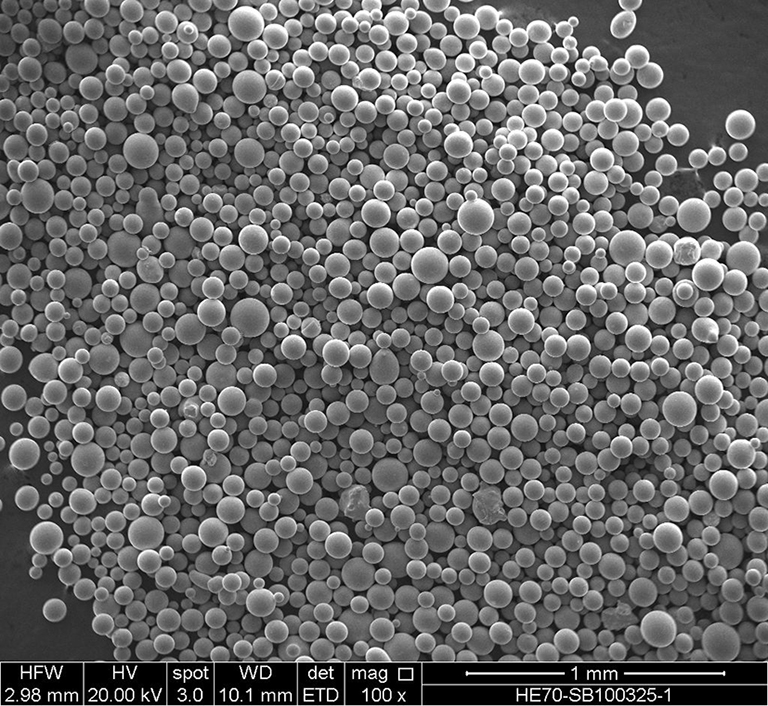

Image

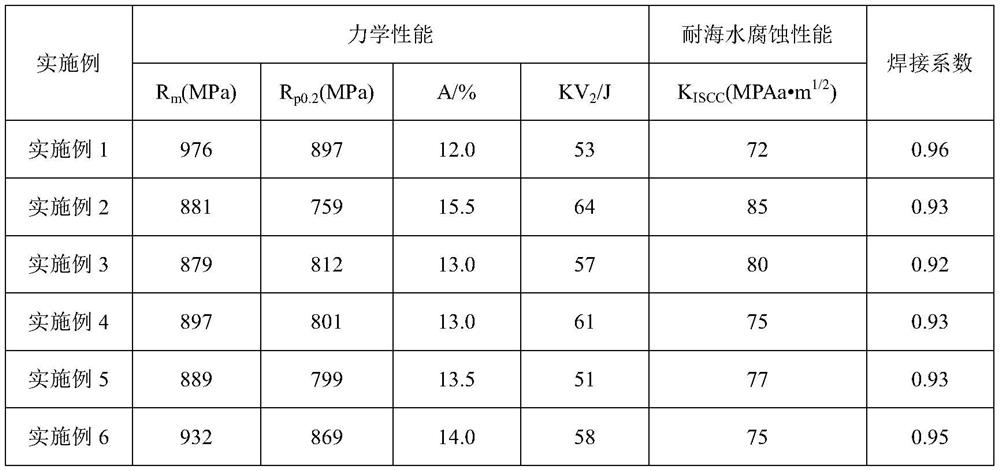

Examples

Embodiment 1

[0033] Example 1: Ti-8Al-2Mo-4Nb-3Zr-Y 0.01%-0.03O alloy

[0034] A 3D printing marine titanium alloy, expressed in mass percentage, said 3D printing marine titanium alloy is composed of the following components: Al 8.0%, Mo 2.0%, Nb 4.0%, Zr 3.0%, Y 0.01%, O 0.03 %, the balance is Ti and unavoidable impurities.

[0035] The preparation method of 3D printing marine titanium alloy powder comprises the following steps:

[0036] (1) Weigh and batch according to the composition of the above-mentioned 3D printing marine titanium alloy, and melt the configured titanium alloy raw materials into titanium alloy ingots three times through mixing, pressing electrode rods, and vacuum consumable electric arc furnace. The melting vacuum degree is 10 -2 Pa; then cast the ingot car and remove the necking;

[0037] (2) The ingot prepared in step (1) is subjected to T β +150℃(T β Indicates the phase transition point temperature of titanium alloy) blanking, forging in the α+β phase zone, fo...

Embodiment 2

[0040] Example 2: Ti-4Al-0.3Mo-1Nb-0.5Zr-Y 0.03%-0.12O alloy

[0041] A 3D printing marine titanium alloy, expressed in mass percentage, said 3D printing marine titanium alloy is composed of the following components: Al 4.0%, Mo 0.3%, Nb 1.0%, Zr 0.5%, Y 0.03%, O 0.12% , and the balance is Ti and unavoidable impurities.

[0042] The preparation method of 3D printing marine titanium alloy powder specifically comprises the following steps:

[0043] (1) Carry out weighing and batching according to the composition of the above-mentioned 3D printing marine titanium alloy, and melt the configured titanium alloy raw materials into alloy ingots three times through mixing, pressing electrode rods, and vacuum consumable electric arc furnace, and the melting vacuum degree is 10 -2 Pa; then cast the ingot car and remove the necking;

[0044] (2) The ingot prepared in step (1) is subjected to T β +150℃(T β Indicates the phase transition point temperature of titanium alloy) blanking, fo...

Embodiment 3

[0047] Example 3: Ti-6Al-1Mo-3Nb-2Zr-Y0.02%-0.08O alloy

[0048] A 3D printing marine titanium alloy, expressed in mass percentage, said 3D printing marine titanium alloy is composed of the following components: Al 6.0%, Mo 1.0%, Nb 3.0%, Zr 2.0%, Y 0.02%, O 0.08% , and the balance is Ti and unavoidable impurities.

[0049] The preparation method of 3D printing marine titanium alloy powder specifically comprises the following steps:

[0050] (1) Carry out weighing and batching according to the composition of the above-mentioned 3D printing marine titanium alloy, and melt the configured titanium alloy raw materials into alloy ingots three times through mixing, pressing electrode rods, and vacuum consumable electric arc furnace, and the melting vacuum degree is 10 -2 Pa; then cast the ingot car and remove the necking;

[0051] (2) The ingot prepared in step (1) is subjected to T β +150℃(T β Indicates the phase transition point temperature of titanium alloy) blanking, α+β pha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com