Wool fabric felt proofing finishing technology

An anti-felting and fabric technology, which is applied in the field of wool fabrics, can solve problems such as the decrease of the breaking strength of wool fabrics and the damage of the internal structure of fibers, and achieve the effects of improving wearing performance, reducing directional friction, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

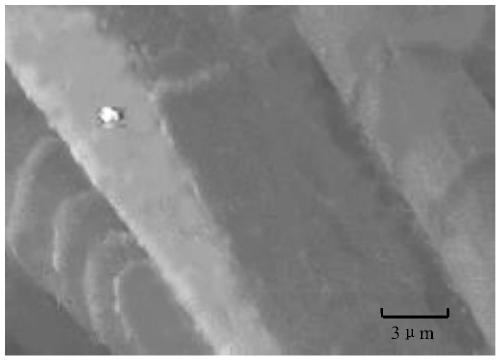

Image

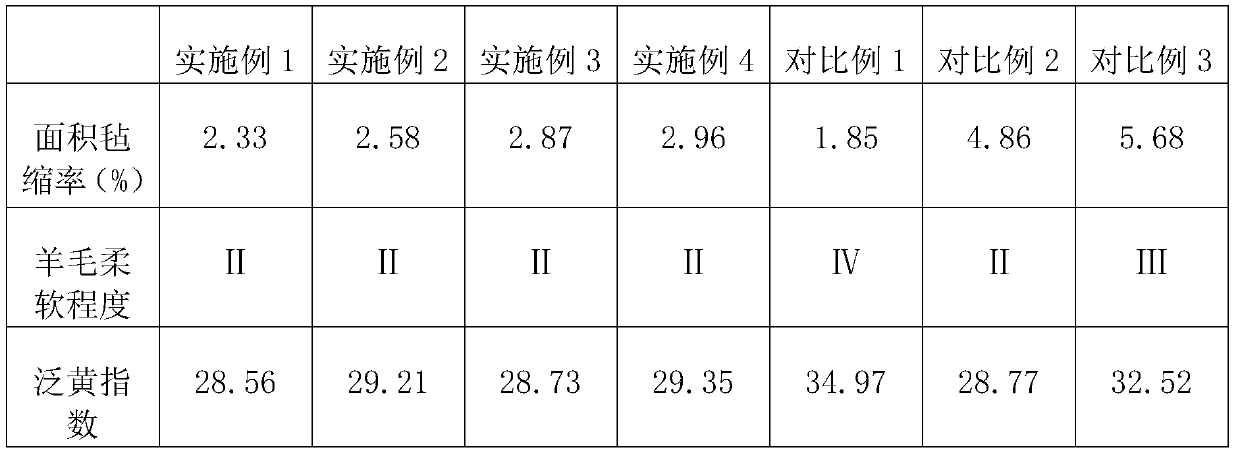

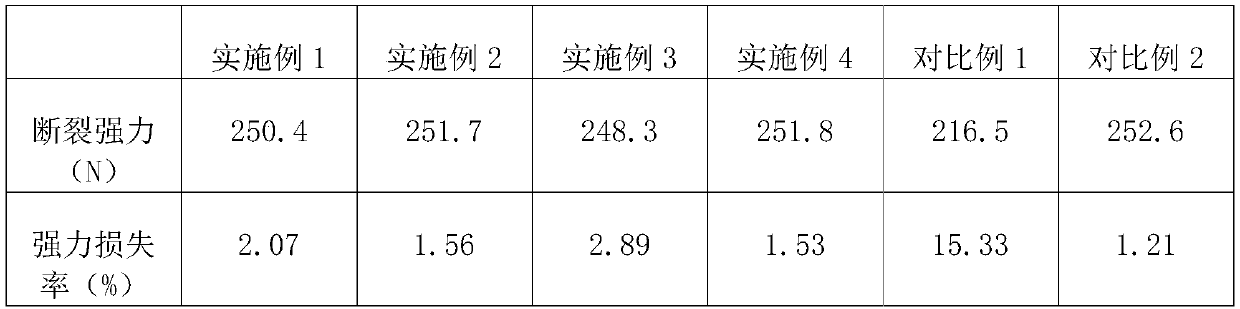

Examples

Embodiment 1

[0031] The preparation method of composite protease comprises the following steps:

[0032]Mix deionized water and absolute ethanol evenly according to the volume ratio of 1:5, add dropwise acetic acid to adjust the pH to 2, and obtain solution a for later use; add tetrabutyl titanate and silicon dioxide micron particles into absolute ethanol, titanium The mass ratio of tetrabutyl ester to silicon dioxide fine particles is 1:7, the mass volume ratio of silicon dioxide micron particles to absolute ethanol is 1g / 30mL, stir evenly to obtain a suspension, according to the ratio of solution a and suspension Add solution a dropwise to the suspension at a rate of 3 drops / second at a volume ratio of 1:5, let stand for 5 hours after the dropwise addition, centrifuge, wash with water, dry in an oven at 50°C for 3 hours, and then send to Put it into a muffle furnace for calcination at 500°C for 3 hours, and cool to obtain pretreated silica micron particles;

[0033] According to the mas...

Embodiment 2

[0039] The preparation method of composite protease comprises the following steps:

[0040] Mix deionized water and absolute ethanol evenly according to the volume ratio of 1:3, add dropwise acetic acid to adjust the pH to 3, and obtain solution a for later use; add tetrabutyl titanate and silicon dioxide micron particles into absolute ethanol, titanium The mass ratio of tetrabutyl ester to silicon dioxide micropowder particles is 1:5, and the mass volume ratio of silicon dioxide microparticles to absolute ethanol is 1g / 30mL. Stir evenly to obtain a suspension. According to the mixture of solution a and suspension, Add solution a dropwise to the suspension at a rate of 3 drops / second at a volume ratio of 1:5, let stand for 4 hours after the dropwise addition, centrifuge, wash with water, dry in an oven at 50°C for 3 hours, and then send to Put it into a muffle furnace for calcination at 500°C for 3 hours, and cool to obtain pretreated silica micron particles;

[0041] Accordi...

Embodiment 3

[0047] The preparation method of composite protease comprises the following steps:

[0048] Mix deionized water and absolute ethanol evenly according to the volume ratio of 1:4, add dropwise acetic acid to adjust the pH to 2.5, and obtain solution a for later use; add tetrabutyl titanate and silicon dioxide micron particles into absolute ethanol, titanium The mass ratio of tetrabutyl ester to silicon dioxide micropowder particles is 1:8, the mass volume ratio of silicon dioxide microparticles to absolute ethanol is 1g / 30mL, stir evenly to obtain a suspension, according to the ratio of solution a and suspension Add solution a dropwise to the suspension at a rate of 3 drops / second at a volume ratio of 1:5, let stand for 6 hours after the dropwise addition, centrifuge, wash with water, dry in an oven at 50°C for 3 hours, and then send to Put it into a muffle furnace for calcination at 500°C for 3 hours, and cool to obtain pretreated silica micron particles;

[0049] According to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com