Three-wire series connection type electronic water gauge circuit

An electronic water gauge and sub-circuit technology, applied in the direction of the liquid level indicator for physical variable measurement, can solve the problems of reducing the anti-interference performance, reducing the water level collection speed, and difficult to adapt to the data update frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

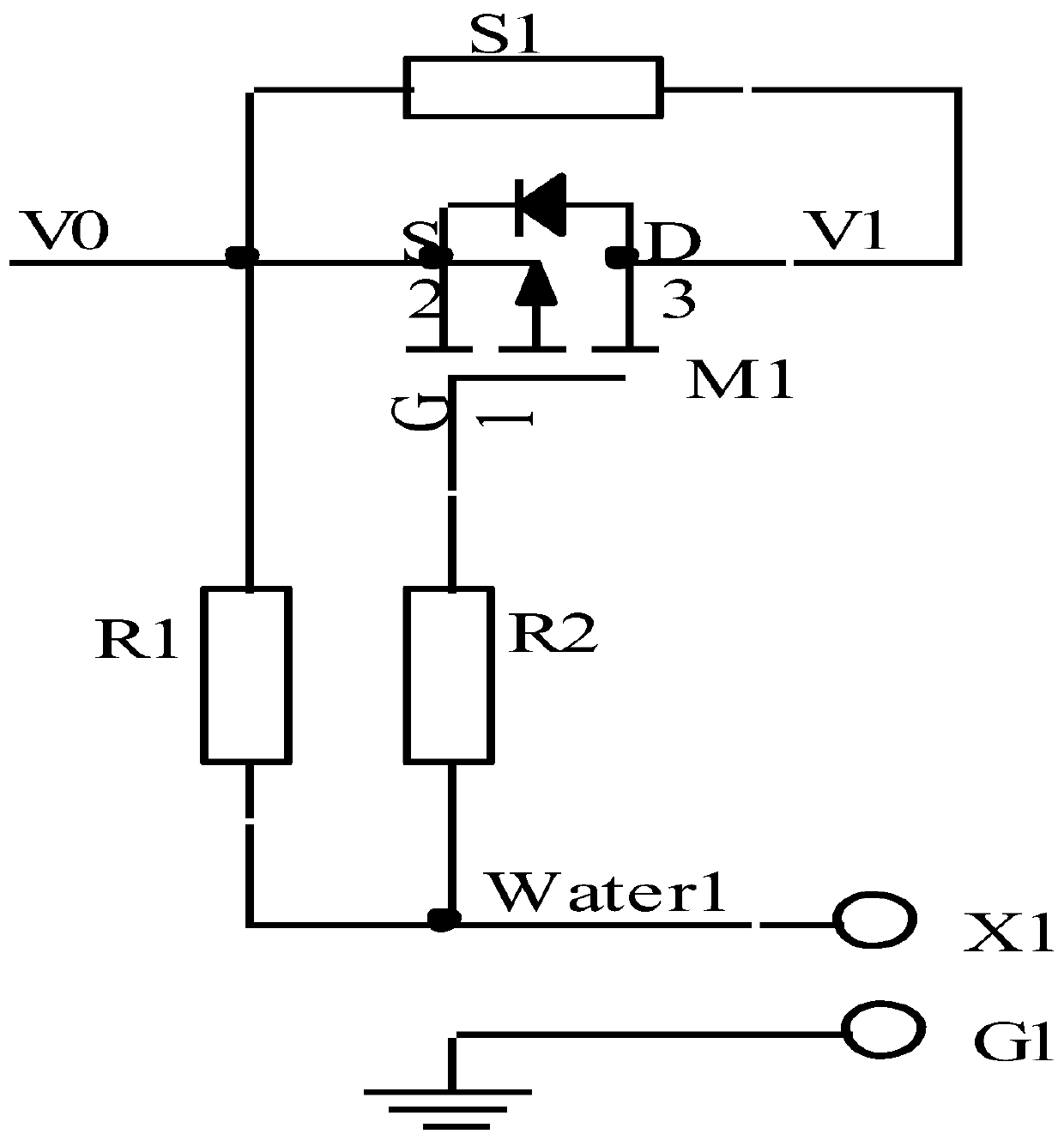

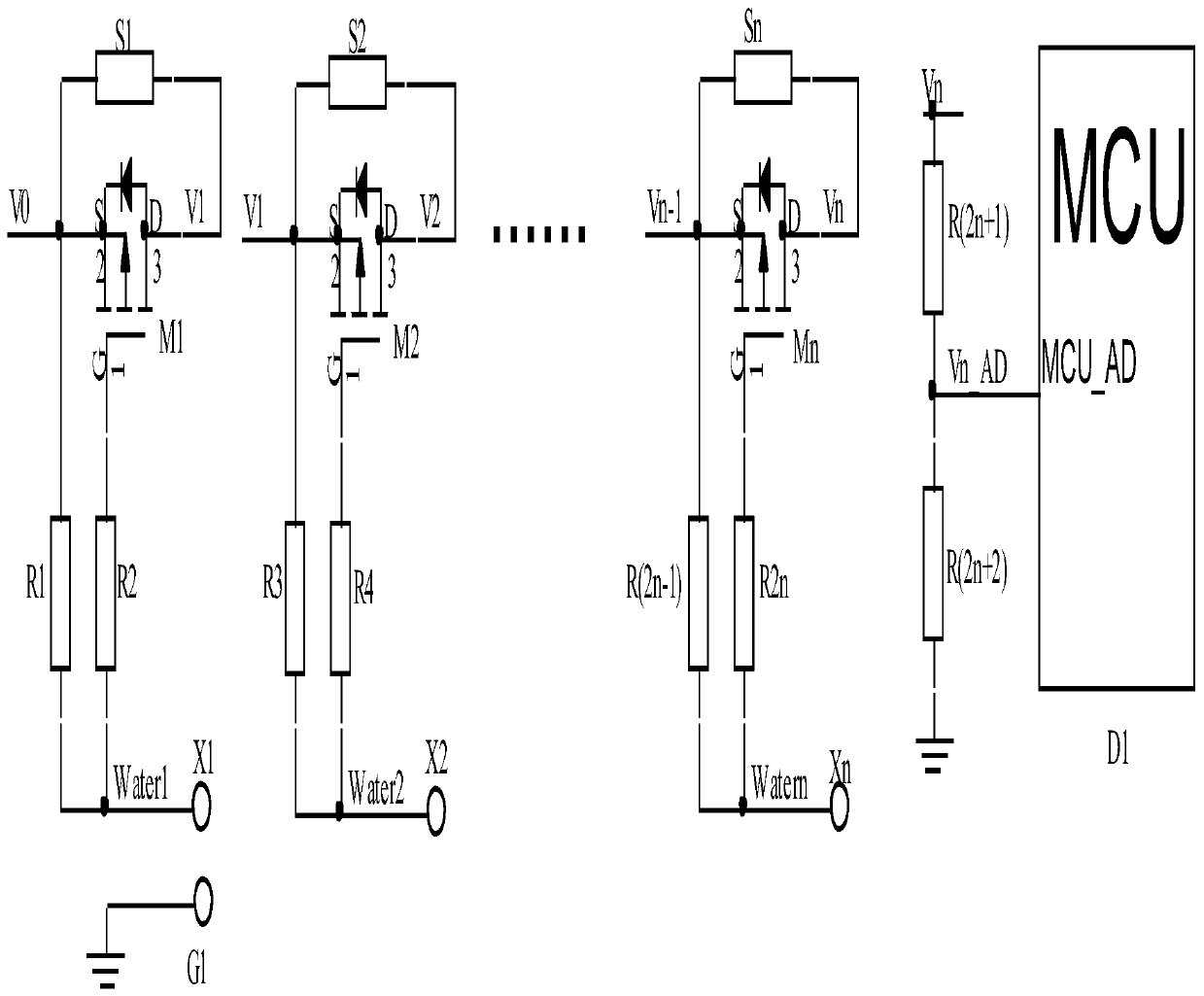

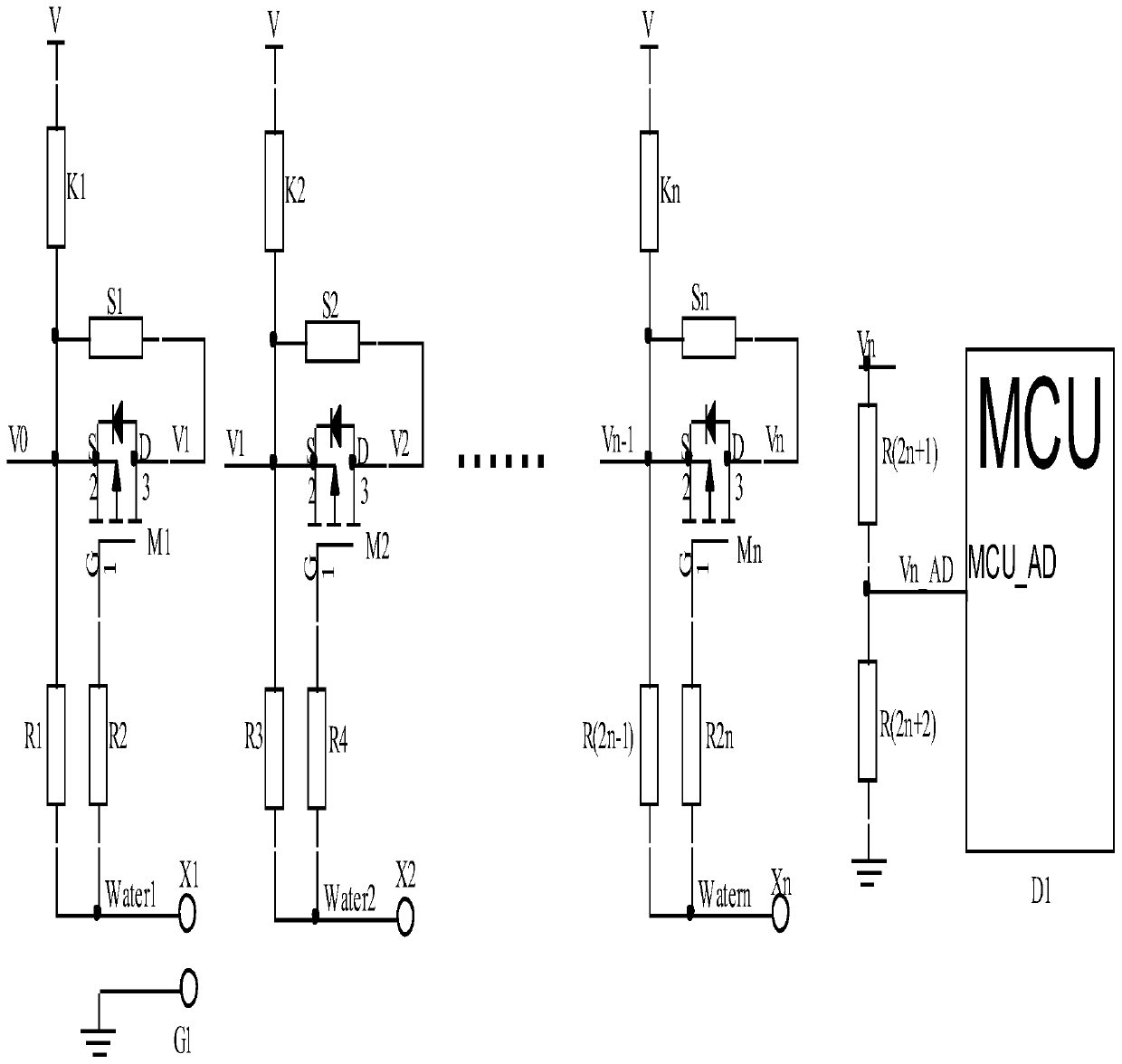

[0032] The invention discloses a three-wire series electronic water gauge circuit, which is composed of cascaded water level detection sub-circuits arranged in series at equal intervals, a voltage dividing circuit, a microprocessor and the like. The water level detection sub-circuit is composed of PMOS tube M1, resistors S1, R1, R2, detection electrode X1 and common pole G1. In the circuit, the signal Water1 is connected to resistors R1 and R2 at the same time, the other leg of R1 and the source of the PMOS tube are connected to the power supply V0 at the same time, the other leg of R2 is connected to the gate of the PMOS tube, the drain of the PMOS tube is the water level detection signal V1, and the current limiting resistor S1 is connected to the PMOS tube. tube source and drain.

[0033] PMOS tube type selection: Considering that the water level detection sub-circuit has a large number of cascaded stages, it is best to choose a PMOS tube with low conduction resistance Rds ...

Embodiment approach 2

[0046] The difference between the second embodiment and the first embodiment is as follows in the selection and calculation method of the current limiting resistor.

[0047] At present, the E48, E96, and E192 series resistors used in electronic products are equal-proportion resistors, and their public ratios q are 1.052, 1.025, and 1.012, respectively, and their accuracy errors are ±2%, ±1%, and ±0.5% / 0.2%. / 0.1%, E192 resistors have high precision and are more expensive. We give priority to using E96 resistors with high cost performance.

[0048] According to the geometric sequence formula, it can be seen that the common ratio q=1.025, and the nth level resistance Sn=S1*q n-1 , the total resistance Sum=S1+S2+S3+......+Sn=S1(1-q n ) / (1-q), considering the actual situation, V0=VCC, that is, R(2n+1)=0, m=0.

[0049] For the convenience of derivation and calculation, we renumbered the current-limiting resistors and sampling resistors to obtain Sn...S3, S2, S1, S0, K1 needs to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com