Method for detecting trace elements in pyrite

A technology for medium and trace elements and detection methods, which is used in measurement devices, preparation of test samples, instruments, etc., can solve problems such as unreported and unclear, and achieve good adsorption effect and increase acid resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0044] Preparation Example 1 Preparation of Modified PUF

[0045] Put 80g of polytetrahydrofuran, 10g of 2-butene-1-thiol, 20g of propylene thiol, 5g of 1,4-butanediol, and 2g of water into the foaming machine and stir to obtain component A, add 80g of MDI and 40g of crude MDI 1. 20 g of p-toluenesulfonyl isothiocyanate, stirred evenly, and foamed at 37° C. for 4 hours to obtain a modified PUF.

preparation example 2

[0046] Preparation example 2 Preparation of modified PUF / peptidoglycan complex

[0047] S1: Put 1 g of the modified PUF prepared in Preparation Example 1 into 100 mL of hydrochloric acid with a concentration of 4 moL / L, and heat the reaction at 90° C. for 4 hours to hydrolyze the bond between the amino group and the isocyanate group to release the amino group. Expose the amino group on the surface to form a modified PUF-NH 2 , dried for later use;

[0048] S2: Use ultrapure water to prepare an aqueous peptidoglycan solution with a concentration of 60g / L, and prepare the modified PUF-NH prepared in the previous step 2 About 1g was put into 100mL of peptidoglycan aqueous solution, heated to 40°C, 15mL of glutaraldehyde solution with a mass concentration of 25% was added dropwise, and the reaction was continued for 24 hours;

[0049] S3: Squeeze out the water from the PUF prepared in the previous step, wash it repeatedly with water for 5 times, and dry it to obtain a modified P...

Embodiment 1

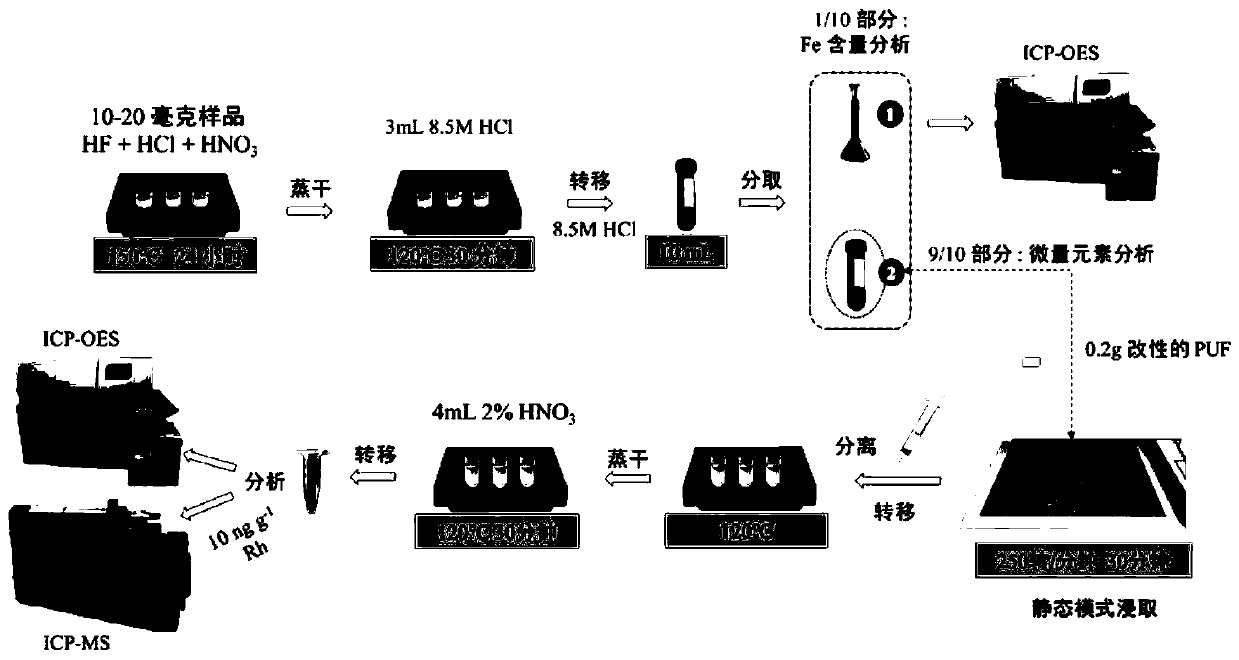

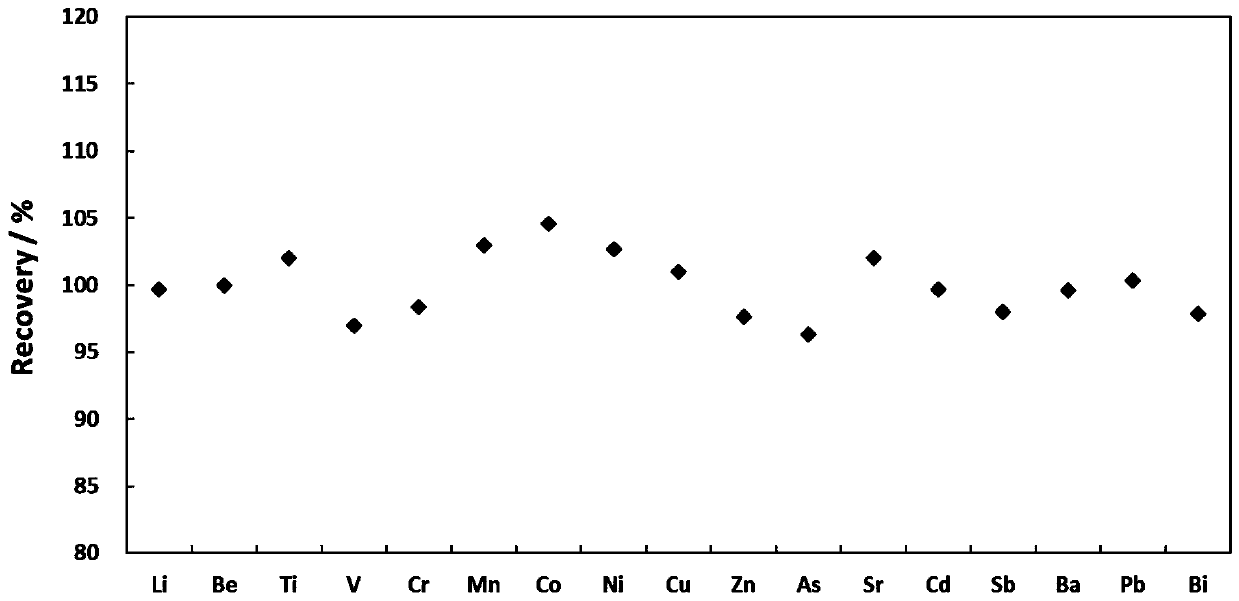

[0056] Trace element detection in the pyrite of embodiment 1

[0057] The purpose of the test: After the modified PUF adsorbs the iron matrix, the difference between the detection results of trace elements in pyrite and the detection results of TRU resin method is compared.

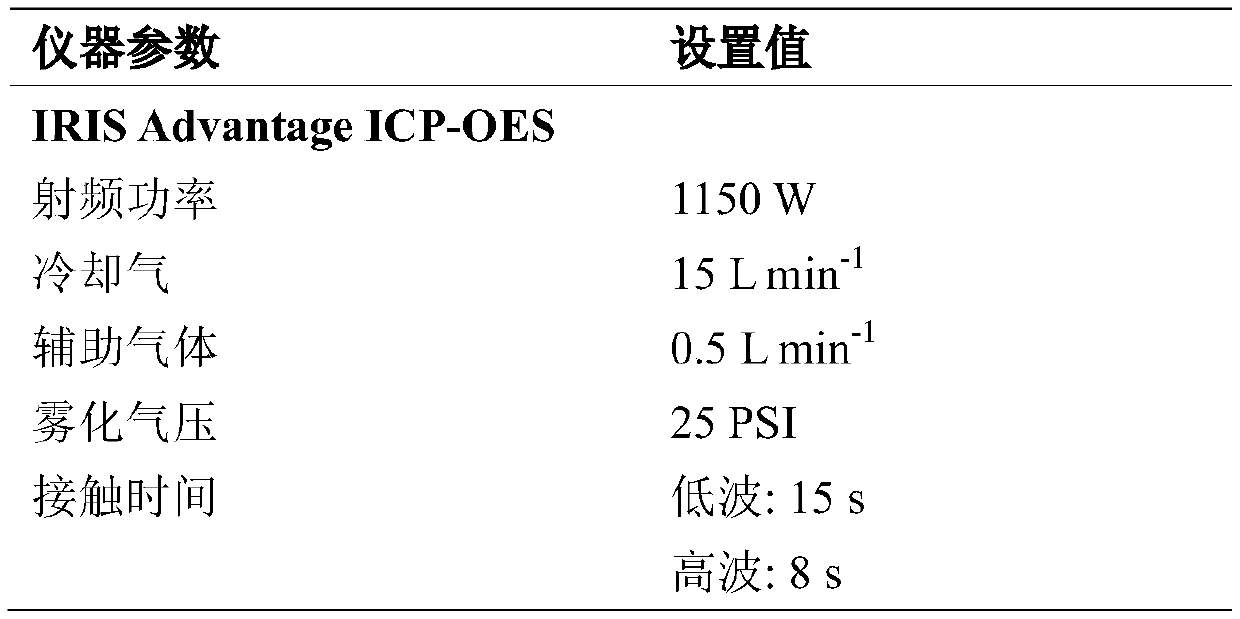

[0058]Experimental method: Accurately weigh 10.02mg of pyrite 17PY-02, put it into a 7mL Savillex PFA vial, use 0.2mL 22M HF, 0.9mL 16M HCl and 0.3mL 14M HNO 3 Heat and dissolve the sample on a hot plate at 150°C for 24 hours, then slowly heat to evaporate HF after cooling, then add 3mL of 8.5M HCl, seal it, heat it on a hot plate at 120°C for 30 minutes to completely dissolve, cool Finally, the sample was transferred to a centrifuge tube using 8.5M HCl solution to make its volume reach 10 mL, and it was weighed accurately. Take 1mL of the sample solution and transfer it to a 50mL volumetric flask, and dilute to the mark with ultrapure water, and measure the iron content in the solution by ICP-OES;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com