An improved ultra-high liquid chromatography-mass spectrometer purification method using acetonitrile

A purification method and an improved technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve problems such as waste water, high personnel operation intensity, and environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

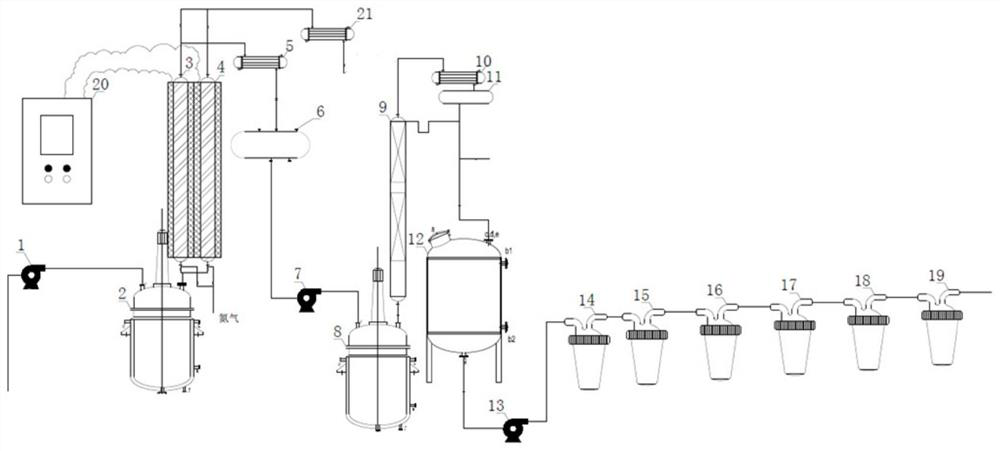

Method used

Image

Examples

Embodiment 1

[0105] This example provides an improved acetonitrile purification process, including the following steps:

[0106] (1) Add industrial acetonitrile containing impurities, water and acetonitrile to the oxidant, the weight percentage of the oxidant industrial acetonitrile is 0.01wt%, and the oxidant is a mixture of potassium superoxide, potassium hydroxide and sodium hydroxide, and the weight ratio is 1:5:8, after oxidation reaction at 80°C and 10KPa pressure for 1 hour, it is sent to the adsorption rectification tower for adsorption, and the obtained top product of the adsorption rectification tower is condensed to obtain a crude product; the adsorption essence The height of the distillation tower is 7m, and the pressure difference between the top and the bottom of the tower is 30kPa, and the number of the adsorption rectification towers is 2, connected in parallel, and 2 adsorption rectification towers are connected with the controller respectively; The rectifying tower is fil...

Embodiment 2

[0114] This example provides an improved acetonitrile purification process, including the following steps:

[0115] (1) Add industrial acetonitrile containing impurities, water and acetonitrile to the oxidant, the weight percentage of the oxidant industrial acetonitrile is 1wt%, and the oxidant is a mixture of potassium superoxide, potassium hydroxide and sodium hydroxide, and the weight ratio is 1 : 5:8, after oxidation reaction at 90°C and 90KPa pressure for 6 hours, it is sent to the adsorption rectification tower for adsorption, and the obtained top product of the adsorption rectification tower is condensed to obtain a crude product; the adsorption rectification The height of the tower is 30m, and the pressure difference between the tower top and the bottom of the tower is 40kPa, and the number of the adsorption rectification towers is 2, connected in parallel, and 2 adsorption rectification towers are connected with the controller respectively; Packing adsorbent in the di...

Embodiment 3

[0123] This example provides an improved acetonitrile purification process, including the following steps:

[0124] (1) Add the industrial acetonitrile containing impurity, water and acetonitrile to oxidant, the weight percent of described oxidant industrial acetonitrile is 0.1wt%, and described oxidant is the mixture of potassium superoxide, potassium hydroxide and sodium hydroxide, and the weight ratio is 1:5:8, after oxidation reaction at 90°C and 60KPa pressure for 4 hours, it is sent to the adsorption rectification tower for adsorption, and the obtained top product of the adsorption rectification tower is condensed to obtain a crude product; the adsorption essence The height of the distillation tower is 20m, and the pressure difference between the tower top and the bottom of the tower is 40kPa, and the number of the adsorption rectification towers is 2, connected in parallel, and 2 adsorption rectification towers are connected with the controller respectively; The rectify...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com