N-type SnS single crystal thermoelectric material and preparation method thereof

A technology of thermoelectric materials and single crystals, which is applied in the direction of thermoelectric device node lead-out materials, polycrystalline material growth, and thermoelectric device manufacturing/processing. It can solve problems that cannot be directly used, and achieve high success rate and crystal growth cycle Short, effect of improving thermoelectric transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

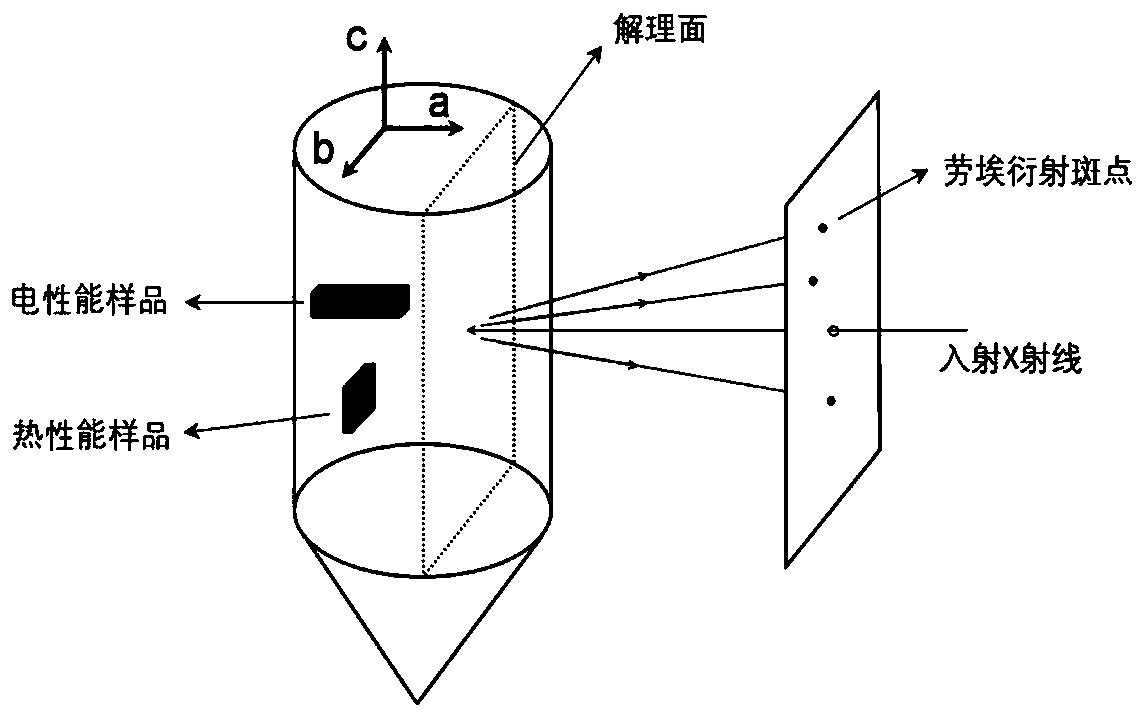

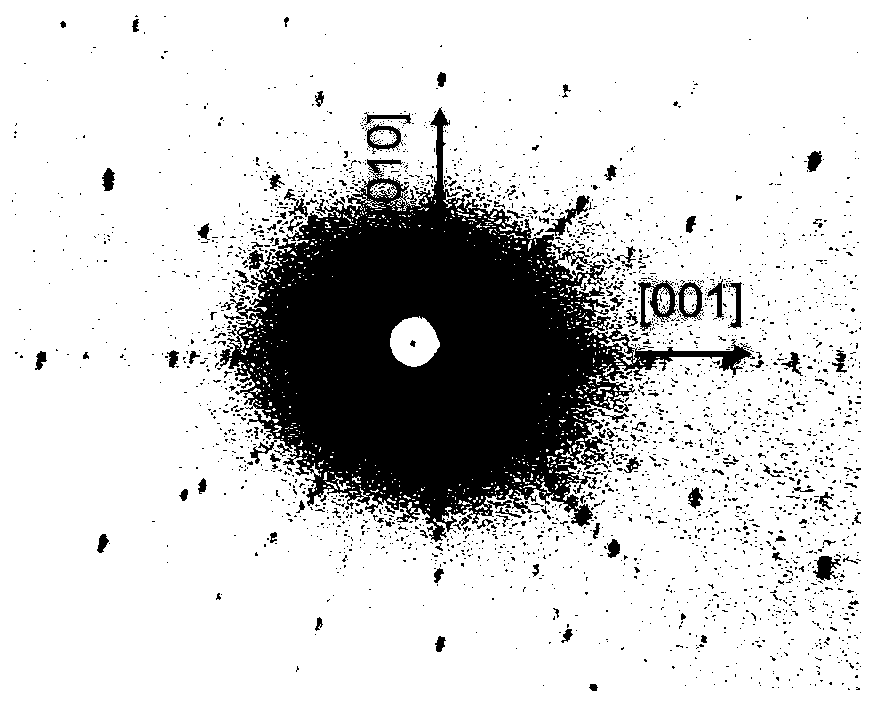

[0037] The invention provides a method for preparing an N-type SnS single crystal thermoelectric material, comprising the following steps:

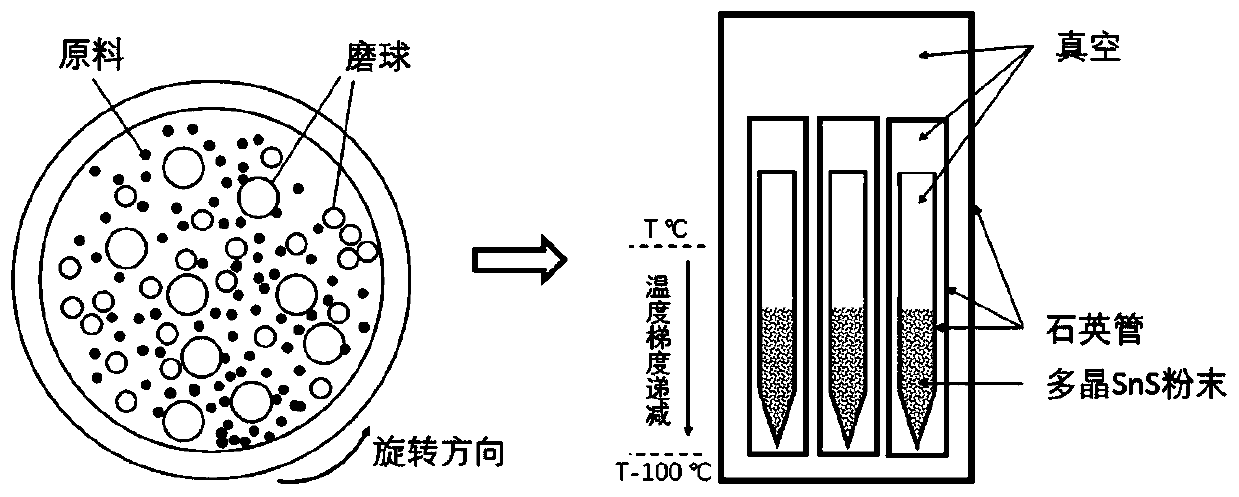

[0038] Sn powder, S powder and SnBr 2 Powder mixing and ball milling to obtain polymorphic SnS powder;

[0039] The polycrystalline SnS powder is directional solidified to obtain an N-type SnS single crystal thermoelectric material.

[0040] In the present invention, unless otherwise specified, all raw materials are commercially available products well known to those skilled in the art.

[0041] The present invention combines Sn powder, S powder and SnBr 2 The powders were mixed and ball milled to obtain polymorphic SnS powder. In the present invention, the Sn powder, S powder and SnBr 2 The purity of the powder is independently preferably ≧99.99% by weight. In the present invention, the Sn powder, S powder and SnBr 2 The powder is preferably mixed according to the molar ratio of Sn, S and Br being 1:(1-x):x; the value range of x is...

Embodiment 1

[0067] According to the molar ratio of Sn, S and Br being 1:0.99:0.01, Sn powder, S powder and SnBr with a purity greater than 99.99% 2 Powder is mixed, obtains the mixed material of 15g;

[0068] Put 15g of the mixed material and 400g of balls into a ball milling tank, and in a nitrogen atmosphere, first ball mill at a speed of 150rpm for 1 hour, then ball mill at a speed of 425rpm for 30 hours, and sieve through 100 meshes to obtain polymorphic SnS powder;

[0069] Put the polymorphic SnS powder into the inner layer quartz tube (diameter is 12mm, the bottom is conical, angle 42 °), vacuumize until the degree of vacuum is less than 10 -3 Pa, sealing the inner quartz tube with flame;

[0070] Place the inner quartz tube sealed with flame in the outer quartz tube (20mm in diameter, with a flat bottom), and evacuate until the vacuum degree is less than 10 -3 Pa, sealing the outer layer quartz tube with a flame to obtain a double-layer quartz tube;

[0071] The double-layer qu...

Embodiment 2

[0078] According to the molar ratio of Sn, S and Br is 1:0.98:0.02, Sn powder, S powder and SnBr with a purity greater than 99.99% 2 Powder is mixed, obtains the mixed material of 15g;

[0079] Put 15g of the mixed material and 400g of balls into a ball milling tank, and in a nitrogen atmosphere, first ball mill at a speed of 150rpm for 1 hour, then ball mill at a speed of 425rpm for 30 hours, and sieve through 100 meshes to obtain polymorphic SnS powder;

[0080] Put the polymorphic SnS powder into the inner layer quartz tube (diameter is 15mm, the bottom is conical, and the angle is 40 °), vacuumize until the degree of vacuum is less than 10° -3 Pa, flame sealing said bottom is a conical quartz tube;

[0081] Place the inner quartz tube sealed with flame in the outer quartz tube (diameter 18mm, flat bottom), and evacuate until the vacuum degree is less than 10 -3 Pa, sealing the outer layer quartz tube with a flame to obtain a double-layer quartz tube;

[0082] The double...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com