Preparation method and application of caulerpa lentillifera extract

A sea grape and extract technology is applied in skin care preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc. , the effect of simple extraction and separation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

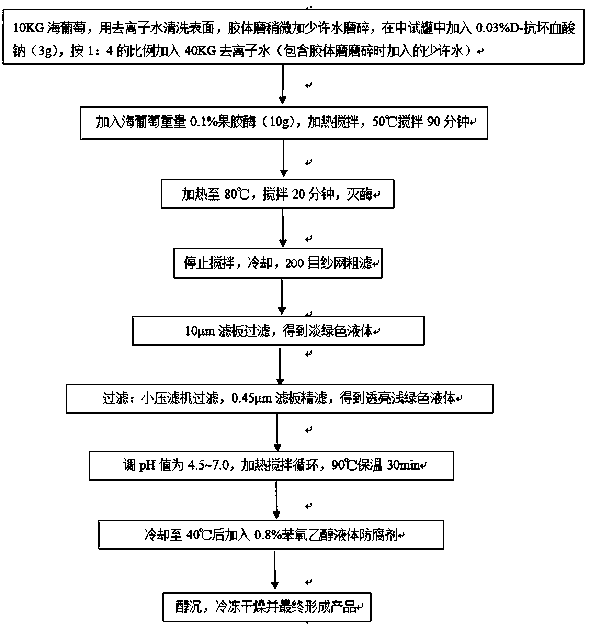

[0027] The preparation of embodiment 1 sea grape extract

[0028] (a) Take by weighing 10kg of cleaned sea grapes, wash its surface with deionized water and place it in a colloid mill, after the colloid mill adds deionized water to grind it slightly, add deionized water with a mass ratio of 4 to sea grapes; add sea grapes Grape weight 0.03% sodium D-ascorbate, add sea grape weight 0.06% mixture of cellulase and pectinase, wherein the mixture of cellulase and pectinase is diluted with deionized water at a mass ratio of 1:50 ;Stir and extract for 120min at a reaction temperature of 40°C and a stirring speed of 50r / min;

[0029] (b) Heat up to 70°C and stir for 30 minutes to inactivate the enzyme; stop heating, cool down to 20°C in water circulation, use 60-mesh gauze for coarse filtration; take the filtrate, use a filter plate with a filter plate pore size of 1 μm to obtain a light green liquid;

[0030] (c) Use a filter plate with a filter plate aperture of 0.1 μm to filter, t...

Embodiment 2

[0032] Embodiment 2: the preparation of sea grape extract

[0033] (a) Take 10 kg of cleaned sea grapes, wash its surface with deionized water and place it in a colloid mill, and after the colloid mill adds deionized water to grind it slightly, add deionized water with a mass ratio of sea grapes of 20; add sea grapes Grape weight 0.03% sodium D-ascorbate, add sea grape weight 0.15% pectinase, pectinase and deionized water are diluted in a mass ratio of 1:60; at a reaction temperature of 60°C, a stirring speed of 100r / Min speed stirring extraction 60min;

[0034] (b) Heat up to 100°C and stir for 15 minutes to inactivate the enzyme; stop heating, cool down to 50°C in water circulation, and use 150-mesh gauze for coarse filtration; take the filtrate and use a filter plate with a filter plate pore size of 8 μm to obtain a light green liquid;

[0035] (c) Use a filter plate with a filter plate aperture of 1 μm to filter to obtain a translucent light green liquid; measure the pH ...

Embodiment 3

[0037] Example 3: Preparation of sea grape extract.

[0038] (a) Take 10kg of cleaned sea grapes, clean its surface with deionized water and place it in a colloid mill, after the colloid mill adds deionized water to grind it slightly, add deionized water with a mass ratio of sea grapes that is 13; add sea grapes 0.03% D-sodium ascorbate by grape weight, add 0.08% cellulase by sea grape weight, wherein cellulase and deionized water are diluted by the mass ratio of 1:70; / min speed stirring extraction 80min;

[0039] (b) Heat up to 80°C and stir for 25 minutes to inactivate the enzyme; stop heating, cool down to 40°C in water circulation, and use 100-mesh gauze for coarse filtration; take the filtrate and use a filter plate with a filter plate pore size of 5 μm to obtain a light green liquid;

[0040] (c) Use a filter plate with a filter plate pore size of 0.2 μm to obtain a translucent light green liquid; measure the pH value, solid content, and electrical conductivity, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com