A kind of solvent type tert-butyl peroxyneodecanoate initiator and application thereof

A technology of tert-butyl peroxyneodecanoate and initiator, which is applied in the field of organic peroxide initiators, and can solve the difficulty of deicing the stock solution of tert-butyl peroxyneodecanoate, easy deicing and difficult deicing of product storage and other problems, to achieve the effect of improving resin morphology, reducing production costs, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

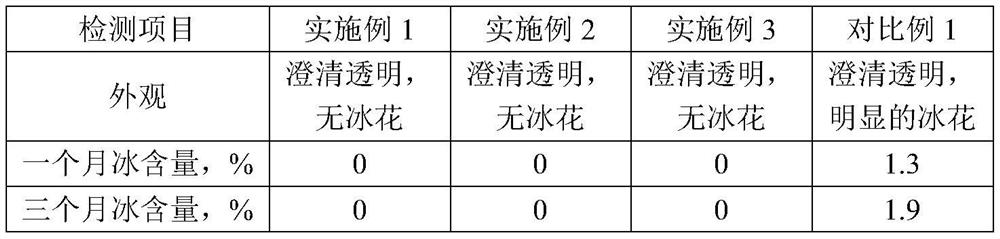

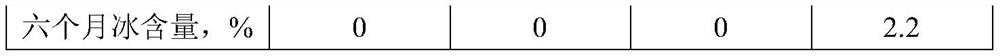

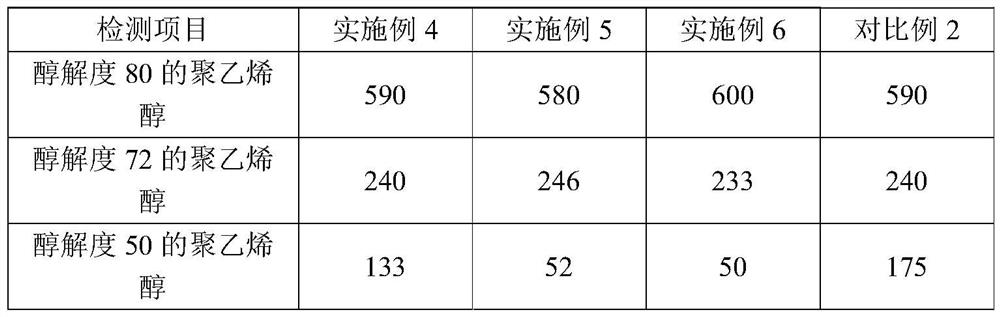

Examples

Embodiment 1-3

[0044] The preparation of embodiment 1-3 solvent type tert-butyl peroxyneodecanoate initiator

Embodiment 1

[0046] (1) 70% tert-butyl hydroperoxide solution and 25% potassium hydroxide lye are mixed and reacted in a mass ratio of 0.35:1 to prepare solution A;

[0047] (2) 99% neodecanoyl chloride is added dropwise in solution A, stir while adding dropwise, temperature is controlled at 20 ℃, the mass ratio of control described neodecanoyl chloride and solution A is 0.37:1, described The neodecanoyl chloride was added dropwise in 45 minutes, stirred and reacted for 90 minutes, and stood to separate water to obtain the crude product;

[0048] (3) washing the crude product with 25% sodium hydroxide lye, standing to divide the water, and then washing with 7.5% sodium bicarbonate solution until the pH is 7 to obtain tert-butyl peroxyneodecanoate;

[0049] (4) Sodium dodecylsulfonate is added to ethanol, the mass ratio of sodium dodecylsulfonate to ethanol is 0.1:100, the addition time is 10min, and stirring is carried out for 45min to obtain solution 1;

[0050] (5) isododecane is added in...

Embodiment 2

[0053] (1) 70% tert-butyl hydroperoxide solution and 25% potassium hydroxide lye are mixed and reacted in a mass ratio of 0.45:1 to prepare solution A;

[0054] (2) 99% neodecanoyl chloride is added dropwise in solution A, stir while adding dropwise, temperature is controlled at 30 ℃, the mass ratio of control described neodecanoyl chloride and solution A is 0.43:1, described The neodecanoyl chloride was added dropwise in 60 minutes, stirred and reacted for 75 minutes, and left standing to separate water to obtain the crude product;

[0055] (3) Wash the crude product with 25% sodium hydroxide lye, let stand to divide the water, and then wash to pH8 with 7.5% sodium bicarbonate solution to obtain tert-butyl peroxyneodecanoate;

[0056] (4) Sodium lauryl sulfate is added to ethylene glycol, the mass ratio of sodium lauryl sulfate to ethylene glycol is 1:100, the addition time is 10min, stirred for 45min, and solution 1 is obtained;

[0057] (5) isododecane is added in the tert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com