A gasoline-electric hybrid multi-energy horizontally opposed internal air-cooled straight-shaft high-speed engine

A horizontally opposed, multi-energy technology, applied in the direction of engine components, engine ignition, machine/engine, etc., can solve the problems of high pressure of friction disc, short life of friction disc, wear of friction disc, etc., and achieve reduction of spindle wear, The effect of extending the service life and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

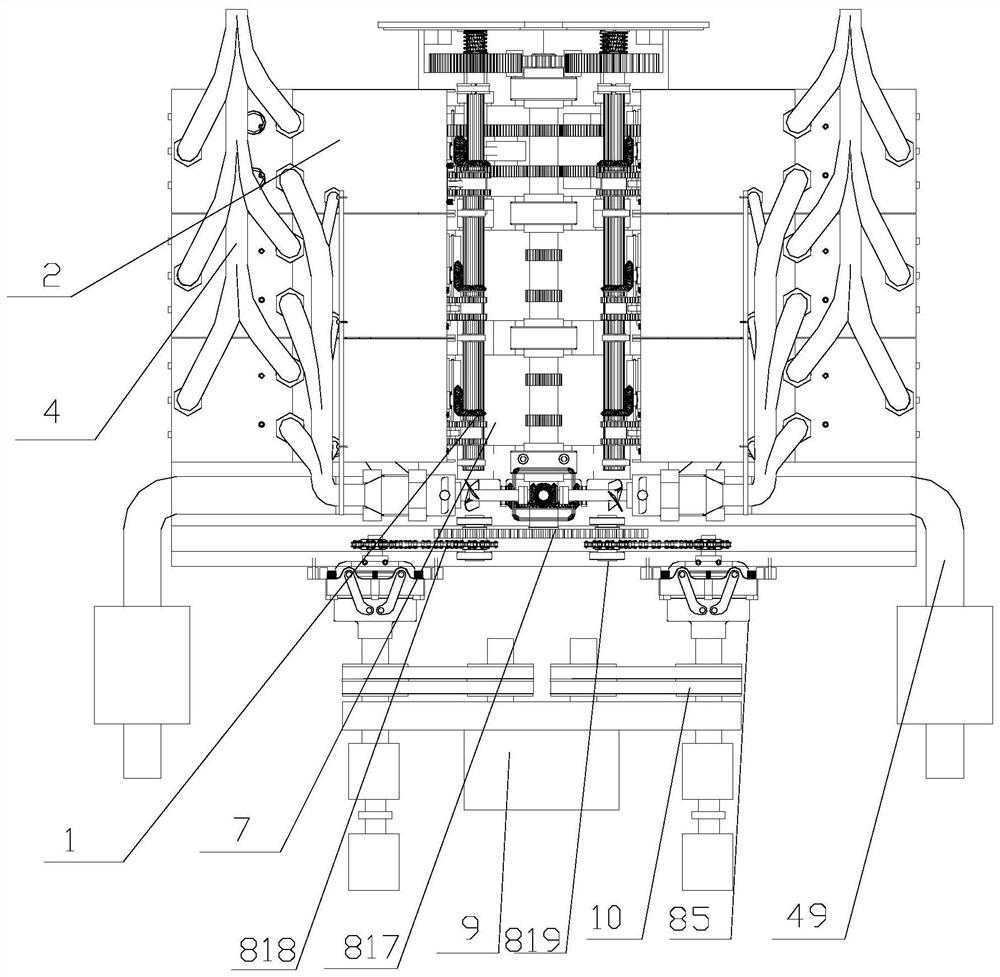

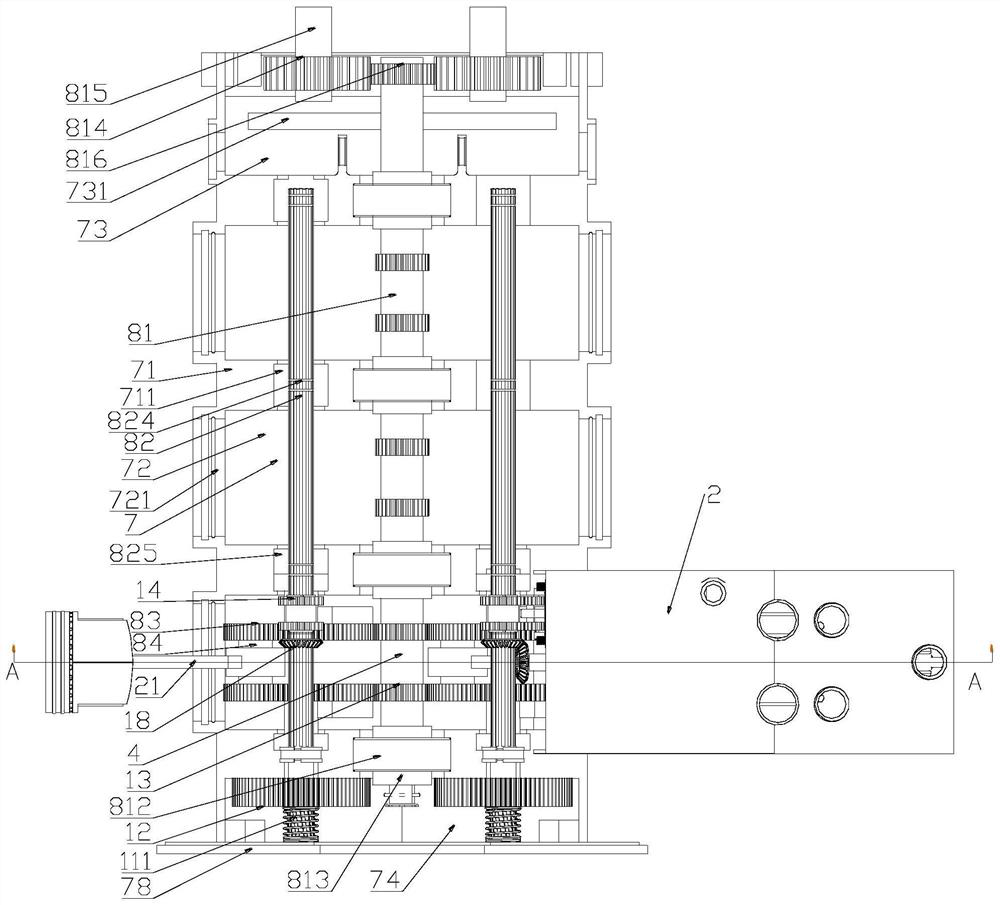

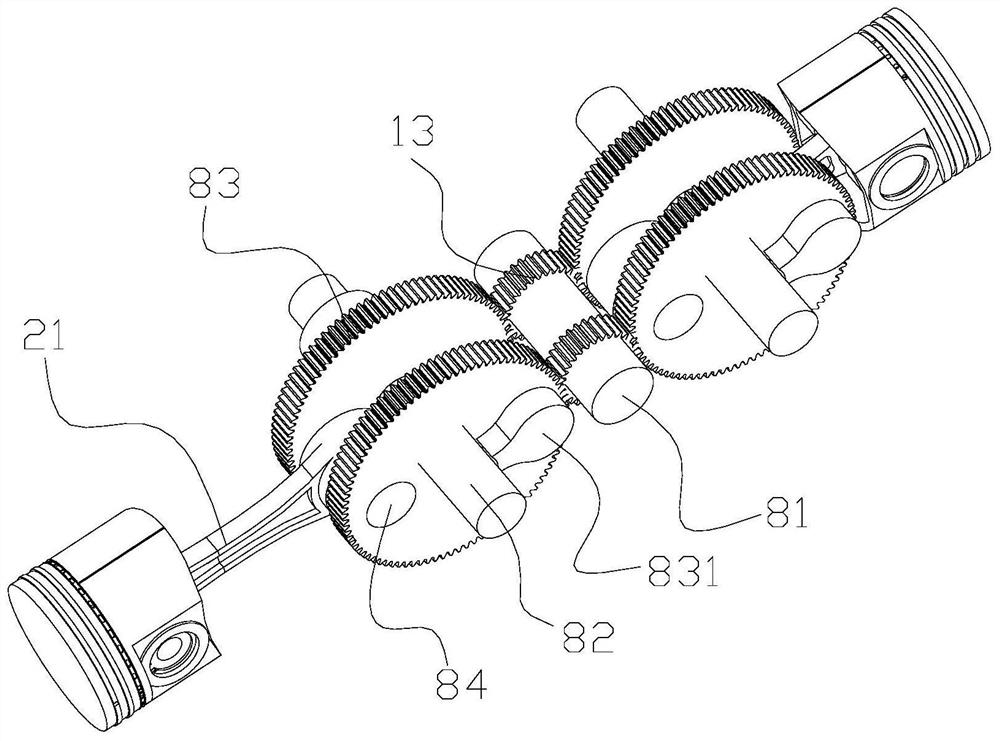

[0079] A gasoline-electric hybrid multi-energy horizontally opposed internal air-cooled direct-shaft high-speed engine, including a transmission assembly 1 installed in a headstock 7; cylinder assemblies 2 are installed on both sides of the headstock 7, and the cylinder assembly 2 are horizontally oppositely installed on the headstock 7, and the cylinder assembly 2 is connected with the transmission assembly 1 as a power part of the transmission assembly 1. A set of transmission assembly 1 is installed in each working groove 72 of the headstock, the transmission assembly 1 is driven by the cylinder assembly 2, and the output power is replaced by a direct shaft to make the engine power output smooth.

[0080] The middle part of the spindle box 7 is alternately provided with a plurality of supporting seats 71 and working grooves 72, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com