A kind of snow melting asphalt and preparation method thereof

An asphalt and snow melting technology, applied in chemical instruments and methods, other chemical processes, building components, etc., can solve the problems of reducing the snow melting function of snow melting asphalt pavement, easy loss of snow melting components, affecting the snow melting durability of snow melting asphalt, etc. Snow melting function, improving snow melting durability, effect of improving snow melting durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: a kind of preparation method of melting snow asphalt comprises the steps:

[0035] (1) Molecular sieve pretreatment: select NaY molecular sieve with a specific surface area of 703㎡ / g, crush it into NaY molecular sieve powder with a pulverizer, sieve with a sieve with a pore size of 125 μm, and select a NaY molecular sieve with a particle size not greater than 125 μm powder; weigh 3.5Kg of sodium nitrate, dissolve it in 60Kg of water, add 14Kg of NaY molecular sieve powder with a particle size not greater than 125 μm, stir evenly, dry at 80°C for 100min, and roast at 400°C for 180min to obtain sodium microporous molecular sieve powder;

[0036] (2) Resin pretreatment: select the styrene-divinylbenzene copolymer ion exchange resin containing the tertiary amine group, the styrene-divinylbenzene copolymer ion exchange resin containing the tertiary amine group is Weak base anion exchange resin, pulverized into resin powder with a pulverizer, sieved with a sie...

Embodiment 2-9

[0040] The difference between embodiment 2-9 and embodiment 1 is that the amount of each raw material in embodiment 2-9 is different, and the process parameters are different.

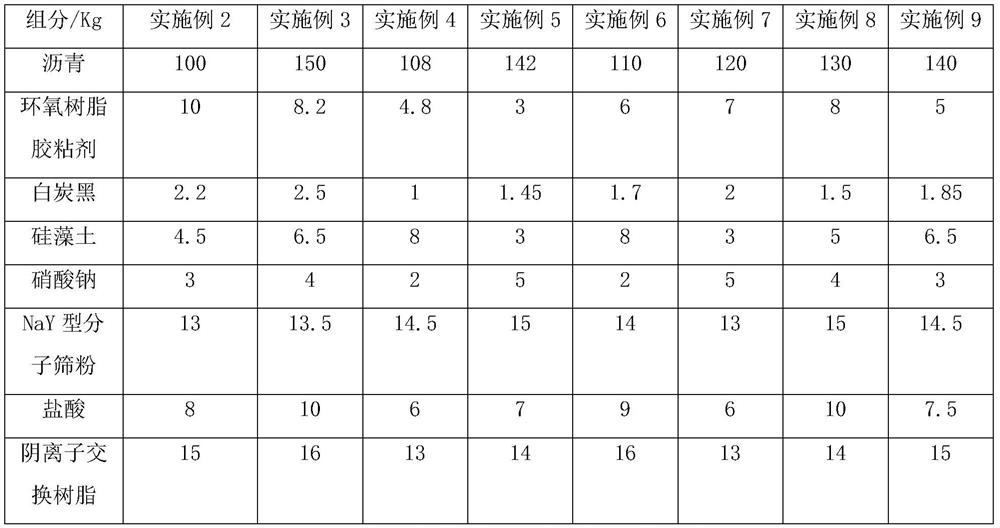

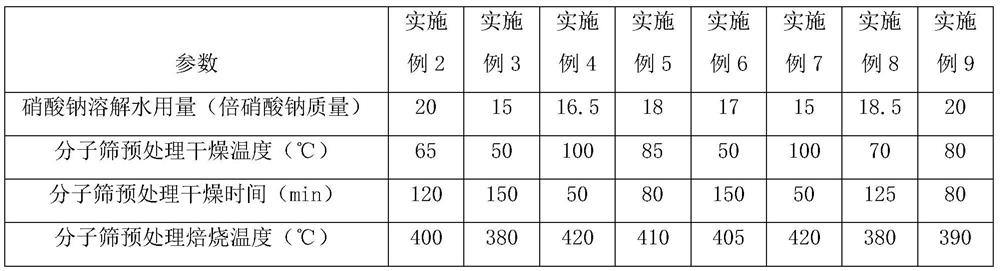

[0041] See Table 1 for the dosage of each raw material in Examples 2-9, and see Table 2 for the process parameters of Examples 2-9.

[0042] The addition of each raw material of table 1 embodiment 2-9

[0043]

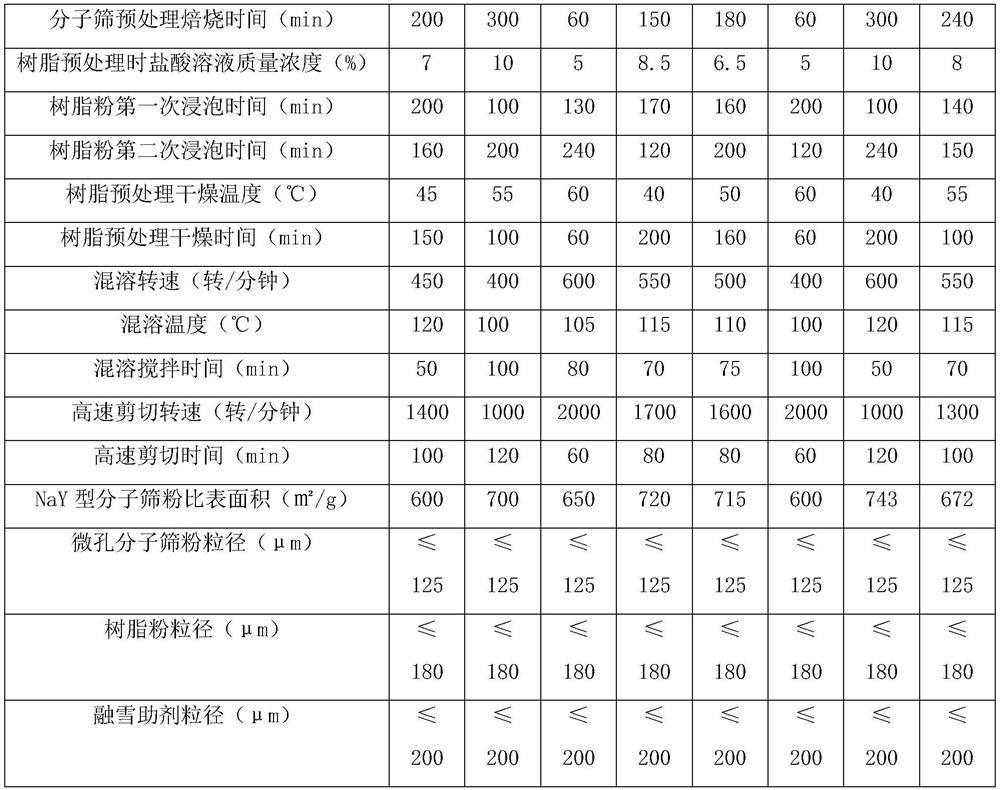

[0044] Parameters in the steps of table 2 embodiment 2-9

[0045]

[0046]

Embodiment 10

[0048] The difference between Example 10 and Example 1 is that Example 10 uses sodium-type ZSM-5 molecular sieve powder instead of NaY-type molecular sieve powder. The specific surface area of sodium-type ZSM-5 molecular sieve powder is 382㎡ / g, and the others are the same as in Example 1. be consistent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com