High-performance lithium ion battery diaphragm and preparation method

A lithium-ion battery, high-performance technology, used in secondary batteries, battery pack components, separators/films/diaphragms/spacers, etc., can solve the problems of insufficient diaphragm performance and inflexible adjustment of composite diaphragm performance. , to achieve the effect of reducing density, good performance stability and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

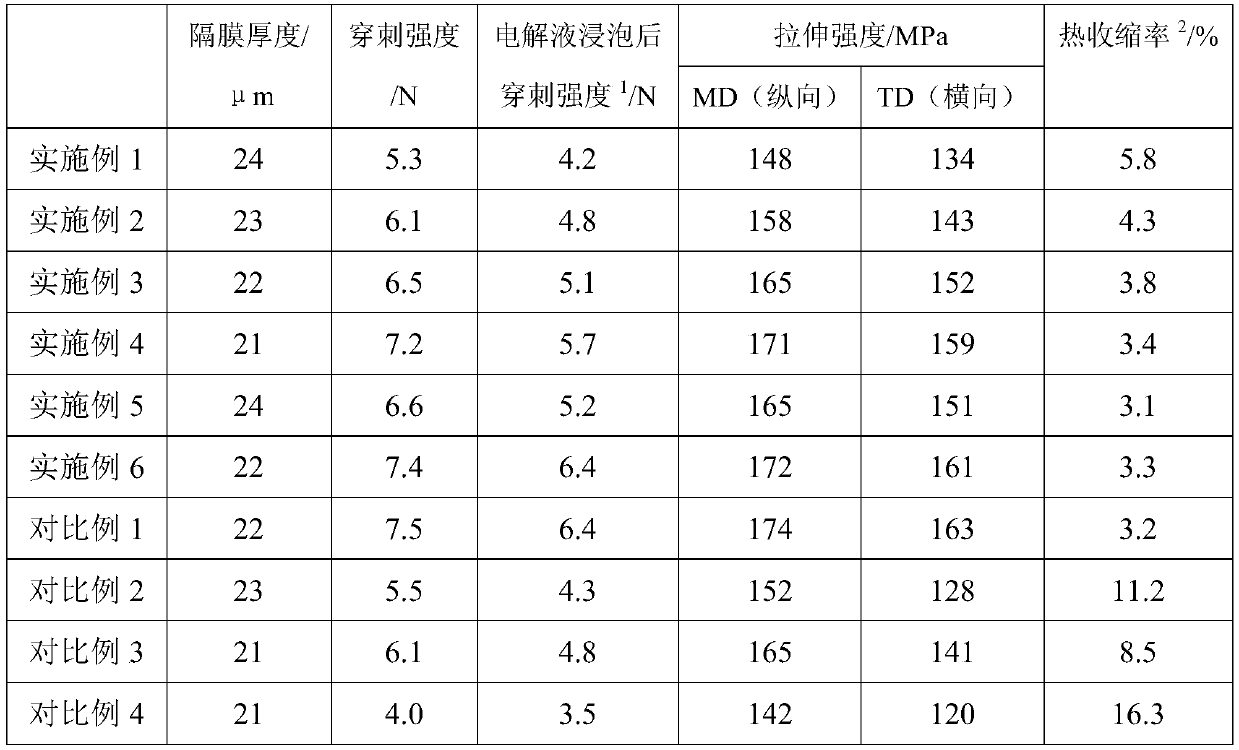

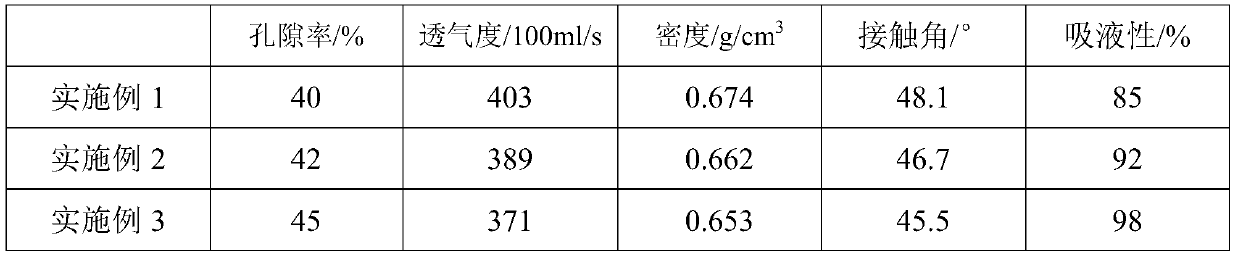

Examples

Embodiment 1

[0033] Mix 1 part of methyl orthosilicate and 5 parts of methanol, add 3 parts of deionized water and mix evenly, add oxalic acid under stirring to adjust the pH to 2.5 for hydrolysis, then add ammonia water to adjust the pH to 9.5 for condensation to obtain a gel. After aging and replacing with absolute ethanol, the glue was soaked in n-dodecyldimethylchlorosilane with a concentration of 10g / L and 3-(methacryloyloxy)propyldimethylchlorosilane with a concentration of 10g / L. The solution was modified for 5 hours, taken out, and dried with supercritical carbon dioxide to obtain n-dodecyl / ester group co-modified silica airgel.

[0034] Take 50 parts of polypropylene, 10 parts of ultra-high molecular weight polypropylene and 1 part of n-dodecyl / ester-based co-modified silica airgel, mix them, and use a granulator to granulate to obtain master batches;

[0035] Mix the masterbatch obtained above, 50 parts of polypropylene, 1 part of anti-aging agent, 1 part of lubricant and 0.3 par...

Embodiment 2

[0037] Mix 1 part of tetraethyl orthosilicate with 8 parts of absolute ethanol, add 4 parts of deionized water and mix evenly, add oxalic acid under stirring to adjust the pH to 2.5 for hydrolysis, then add ammonia water to adjust the pH to 9.5 for condensation to obtain a gel. Said gel was aged, replaced with absolute ethanol, soaked into n-tetradecyl dimethyl chlorosilane concentration of 40g / L and 3-(methacryloyloxy) propyl dimethyl chlorosilane concentration of 30g / L L solution was modified for 3 hours, taken out, and dried with supercritical carbon dioxide to obtain n-tetradecyl / ester group co-modified silica airgel.

[0038] Take 50 parts of polypropylene, 15 parts of ultra-high molecular weight polypropylene and 3 parts of n-tetradecyl / ester-based co-modified silica airgel, mix them, and use a granulator to granulate to obtain master batches;

[0039] Mix the masterbatch obtained above, 50 parts of polypropylene, 1 part of anti-aging agent, 1 part of lubricant, 1 part o...

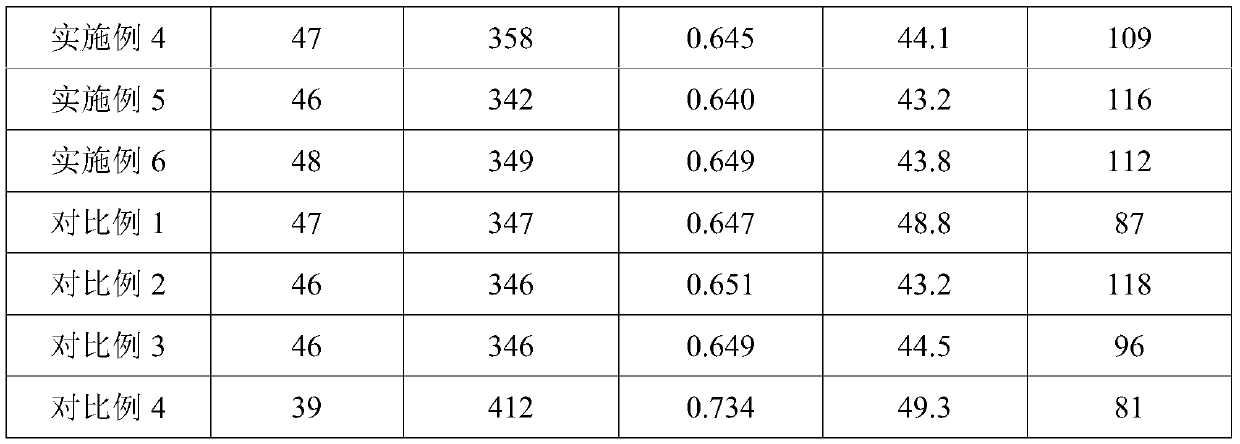

Embodiment 3

[0041] Mix 1 part of tetraethyl orthosilicate with 8 parts of absolute ethanol, add 4 parts of deionized water and mix evenly, add oxalic acid under stirring to adjust the pH to 2.5 for hydrolysis, then add ammonia water to adjust the pH to 9.5 for condensation to obtain a gel. Said gel was aged, replaced with absolute ethanol, soaked into n-hexadecyl dimethyl chlorosilane concentration of 70g / L and 3-(methacryloyloxy) propyl dimethyl chlorosilane concentration of 60g / L L solution was modified for 2 hours, taken out, and freeze-dried to obtain n-hexadecyl / ester group co-modified silica airgel.

[0042] Take 50 parts of polypropylene, 25 parts of ultra-high molecular weight polypropylene and 5 parts of n-hexadecyl / ester-based co-modified silica airgel, mix them, and use a granulator to granulate to obtain master batches;

[0043] Mix the masterbatch obtained above, 50 parts of polypropylene, 1 part of anti-aging agent, 1.5 parts of lubricant and 2 parts of β-nucleating agent, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com