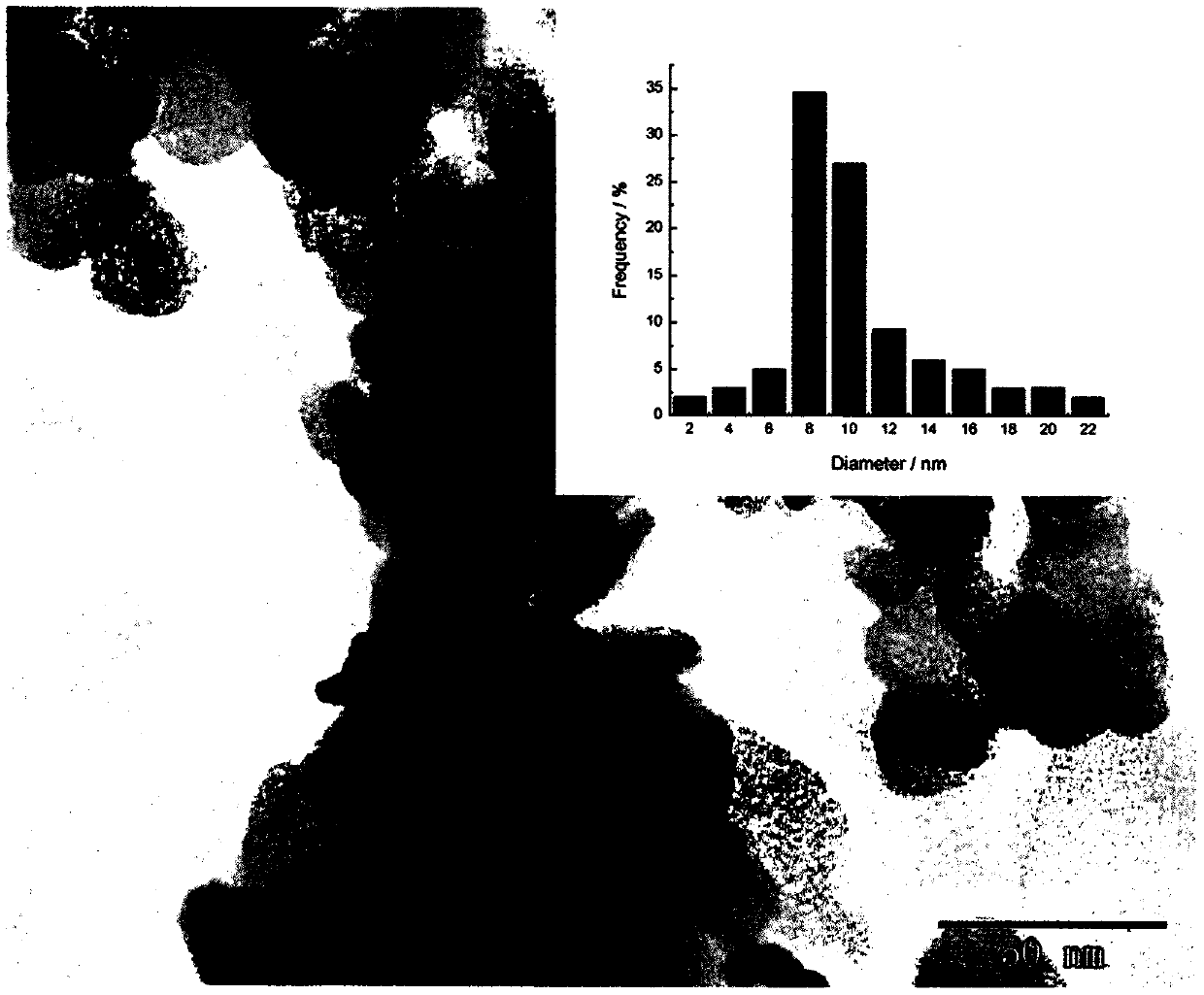

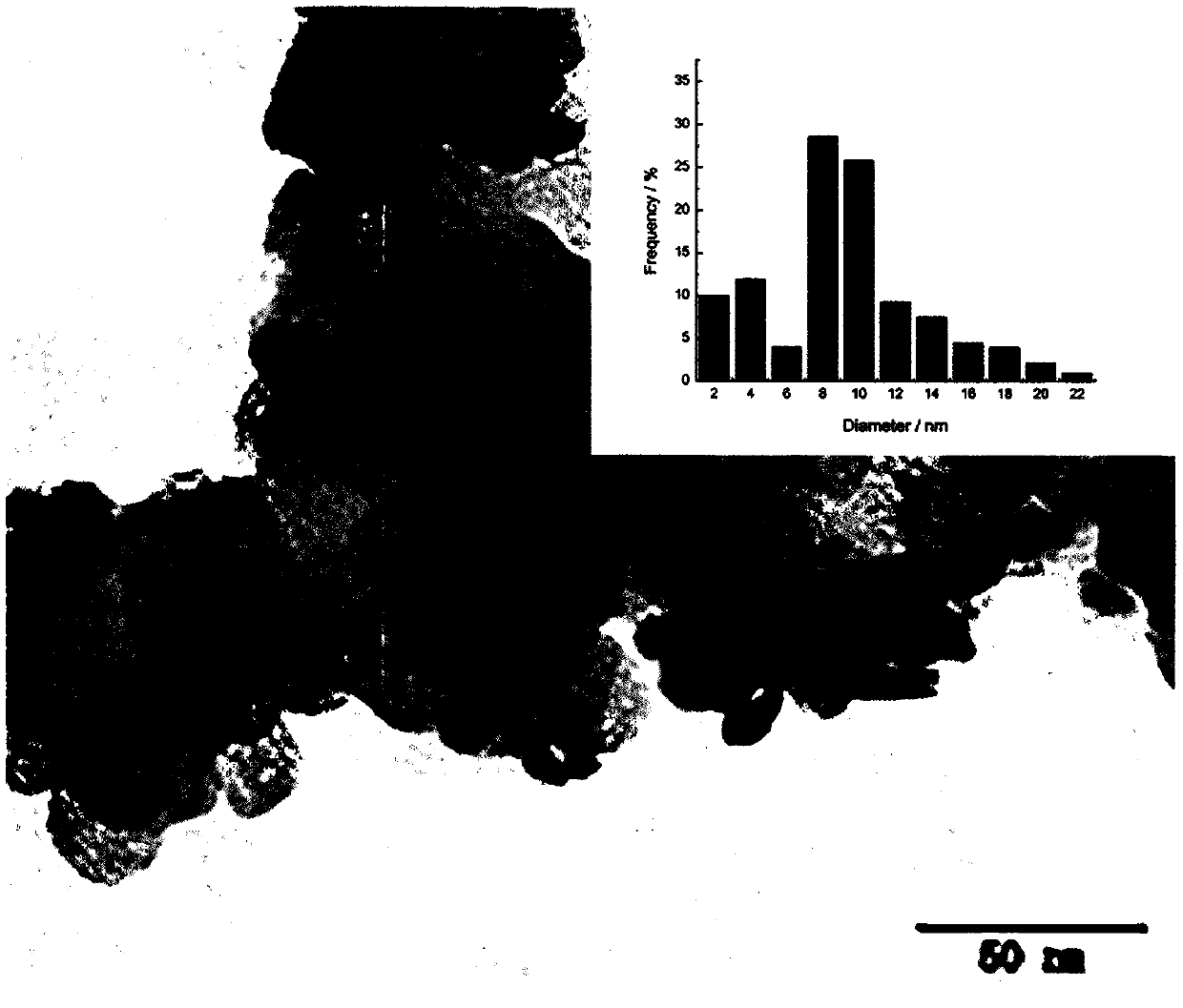

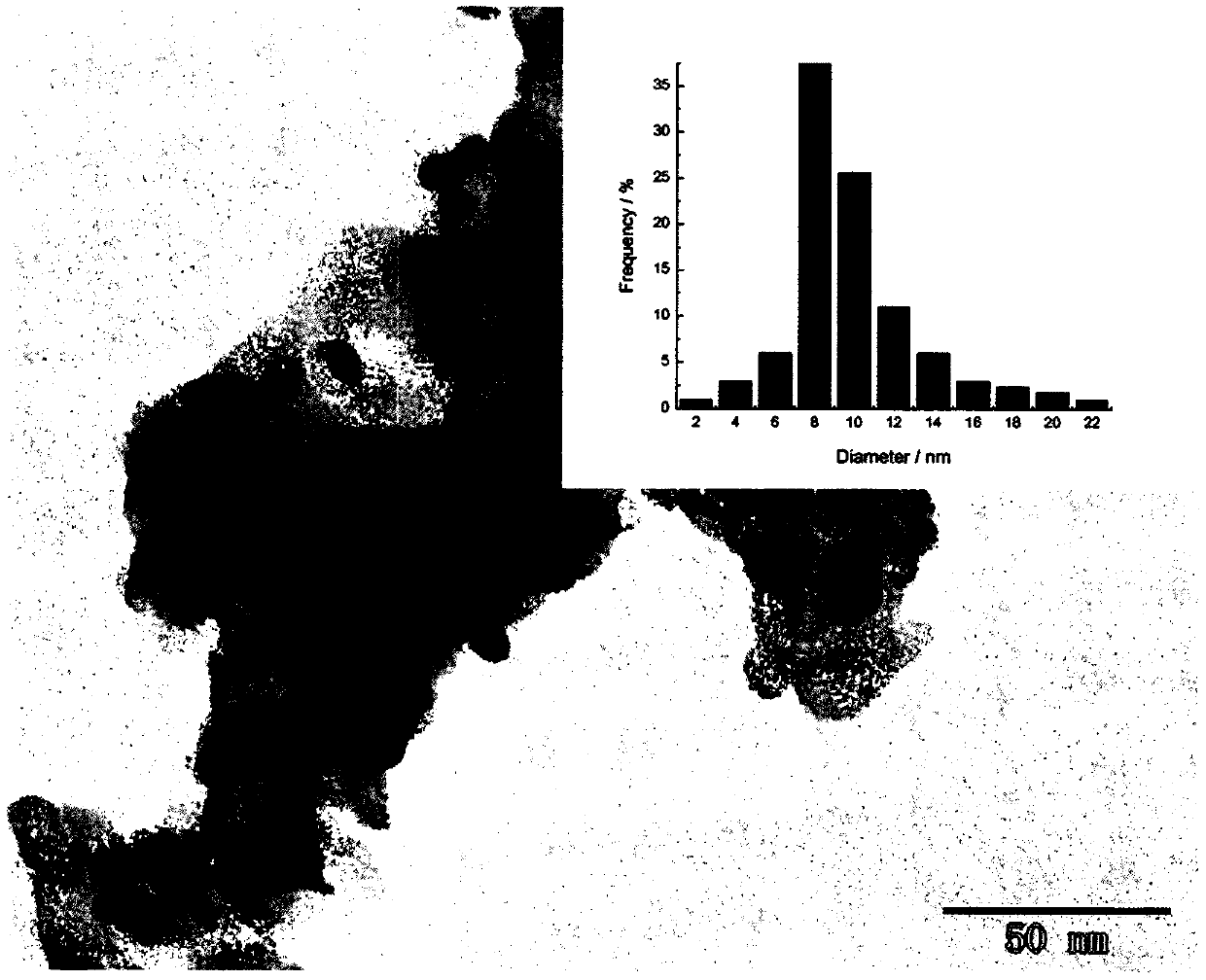

Preparation method of Pd-PdH0. 706-PdO-NiOxHy/C core-shell electrocatalyst

An electrocatalyst, 0.048gvulcanxc-72r technology, applied in circuits, electrical components, battery electrodes, etc., can solve problems such as poor control of nanoparticle size and distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0023] Embodiment 1: In the second step of the preparation process, the amount of 1M KOH aqueous solution is 8ml; other preparation conditions remain unchanged. The catalyst prepared by this embodiment is denoted as: Pd-PdH 0.706 @PdO-NiO x h y / C-8.

Embodiment approach 2

[0024] Embodiment 2: In the second step of the preparation process, the amount of 1M KOH aqueous solution is 9 ml; other preparation conditions remain unchanged. The catalyst prepared by this embodiment is denoted as: Pd-PdH 0.706 @PdO-NiO x h y / C-9.

Embodiment approach 3

[0025] Embodiment 3: In the second step of the preparation process, the amount of 1M KOH aqueous solution is 10ml; other preparation conditions remain unchanged. The catalyst prepared by this embodiment is denoted as: Pd-PdH 0.706 @PdO-NiO x h y / C-10.

[0026] Embodiment 4: In the second step of the preparation process, the amount of 1M KOH aqueous solution is 11 ml; other preparation conditions remain unchanged. The catalyst prepared by this embodiment is denoted as: Pd-PdH 0.706 @PdO-NiO x h y / C-11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com